Bio-safety disposal method for dispelling dichlorodifluoromethane by induction heating and pyrolysis induction heating furnace

An induction heating furnace and induction heating technology, applied in lighting and heating equipment, furnaces, crucible furnaces, etc., can solve problems such as difficulty in popularization and application, hidden safety hazards, and increased processing costs, and achieve convenient start-up operation and high energy utilization. , the effect of fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

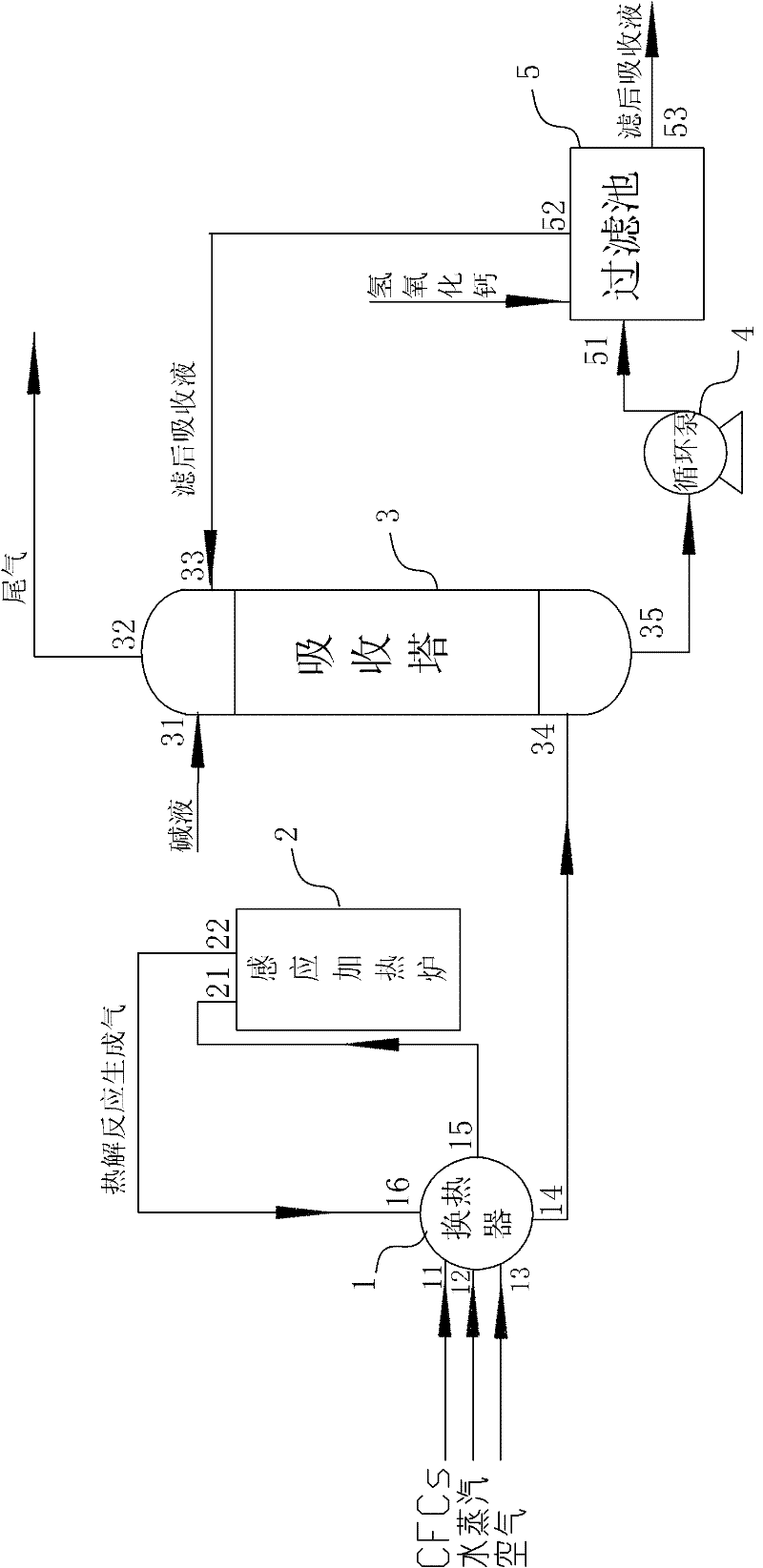

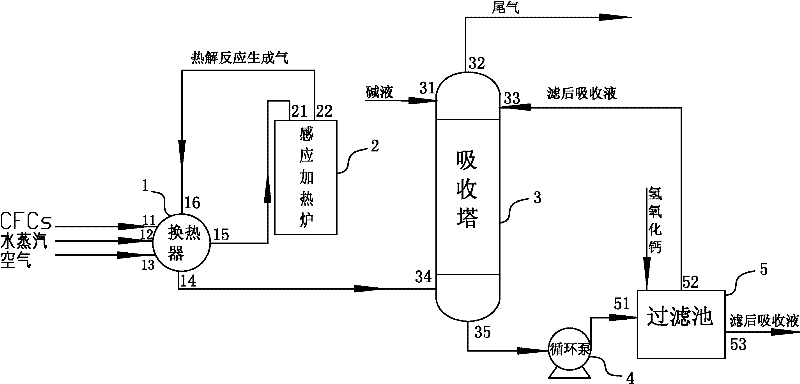

Method used

Image

Examples

Embodiment 1

[0028] Using commercially available Freon F-11, namely CCl 3 F. The processing steps are as follows:

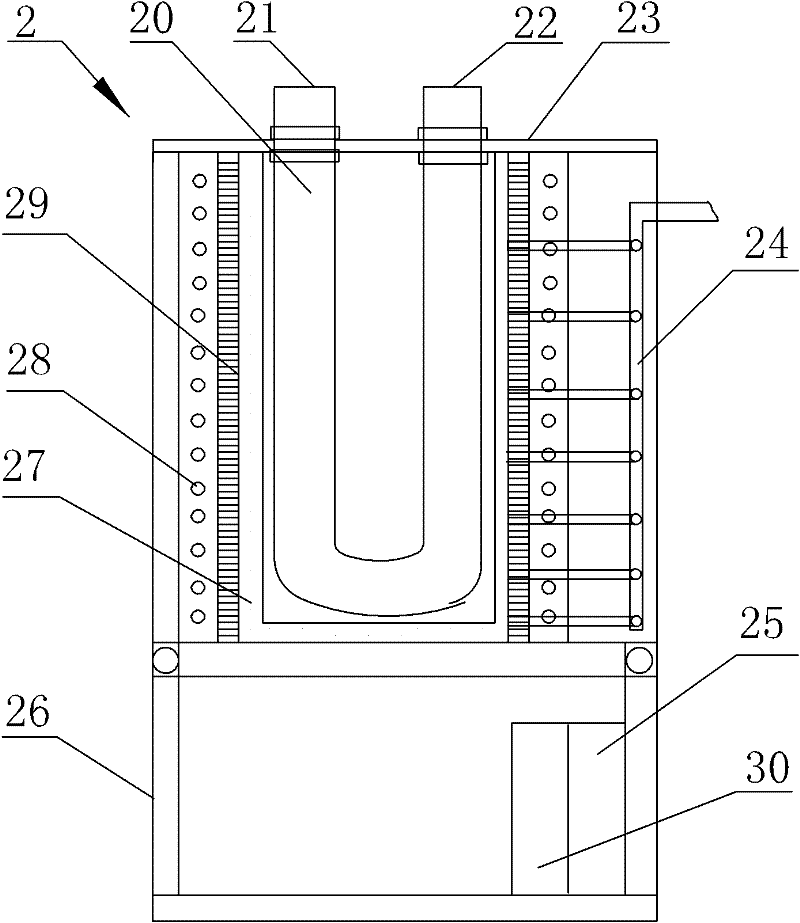

[0029] (1) Heat the temperature of the metal coil in the cavity of the pyrolysis induction heating furnace 2 to 1000°C and maintain a constant temperature;

[0030] (2) According to the design processing capacity range of the pyrolysis induction heating furnace 1mol / min, the processing capacity of CFCs is determined to be 0.25mol / min. 0.25mol / minCCl 3 F and 0.75 mol / min water vapor are respectively introduced into the heat exchanger 1 through the heat exchanger tube side inlets 11 and 12, and through the heat exchanger 1, the gas inlet 21 of the metal coil 20 of the pyrolysis induction heating furnace 2 Into the metal coil after constant temperature, the residence time of the gas in the metal coil is 1min, and the pyrolysis reaction formula is shown in formula (2):

[0031] CCl 3 F+2H 2 O→CO 2 +3HCl+HF (2); After a full pyrolysis reaction, the pyrolysis reaction gas is discharge...

Embodiment 2

[0036] Using commercially available Freon F-152, namely C 2 ClF 5 . The processing steps are as follows:

[0037] (1) Heat the temperature of the metal coil in the cavity of the pyrolysis induction heating furnace 2 to 1300°C and maintain a constant temperature;

[0038] (2) According to the design processing capacity range of the pyrolysis induction heating furnace 1mol / min, the processing capacity of CFCs is determined to be 0.1mol / min. Make up 0.1mol / minC of raw gas 2 ClF 5 , 0.6mol / min water vapor and 0.3mol / min air are respectively introduced into the heat exchanger 1 through the heat exchanger tube side inlets 11, 12, and 13, and through the heat exchanger 1, the metal in the pyrolysis induction heating furnace 2 The inlet port 21 of the coil 20 is led into the metal coil 20 after a constant temperature, the residence time of the gas in the metal coil is 7 minutes, and the pyrolysis reaction formula is shown in formula (3):

[0039] 2C 2 ClF 5 +6H 2 O+O 2 →4CO 2 +10HF+2HCl ...

Embodiment 3

[0044] Using commercially available Freon F-12, namely CCl 2 F 2 . The processing steps are as follows:

[0045] (1) Heat the temperature of the metal coil in the cavity of the pyrolysis induction heating furnace 2 to 1200°C and maintain a constant temperature;

[0046] (2) According to the design processing capacity range of the pyrolysis induction heating furnace 1mol / min, the processing capacity of CFCs is determined to be 0.14mol / min. The 0.14mol / min CCl that constitutes the raw gas 2 F 2 And 0.84mol / min water vapor are respectively passed into the heat exchanger 1 through the heat exchanger tube side inlets 11 and 12, and passed through the heat exchanger 1 through the inlet 21 of the metal coil 20 of the pyrolysis induction heating furnace 2. Into the metal coil 20 after the constant temperature, the residence time of the gas in the metal coil is 5 minutes, and the pyrolysis reaction formula is shown in formula (5):

[0047] CCl 2 F 2 +2H 2 O→CO 2 +2HCl+2HF (5); after full ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com