Method and system for realizing balanced production of whole-automobile general assembly shop

A technology of equalization in the assembly workshop, which is applied in the field of balanced production in the automobile assembly workshop, which can solve the problems of missing materials at the production line, wasting time, and uneven load of production line stations, so as to improve the ability of balanced production and ensure balance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and example the invention is described in further detail.

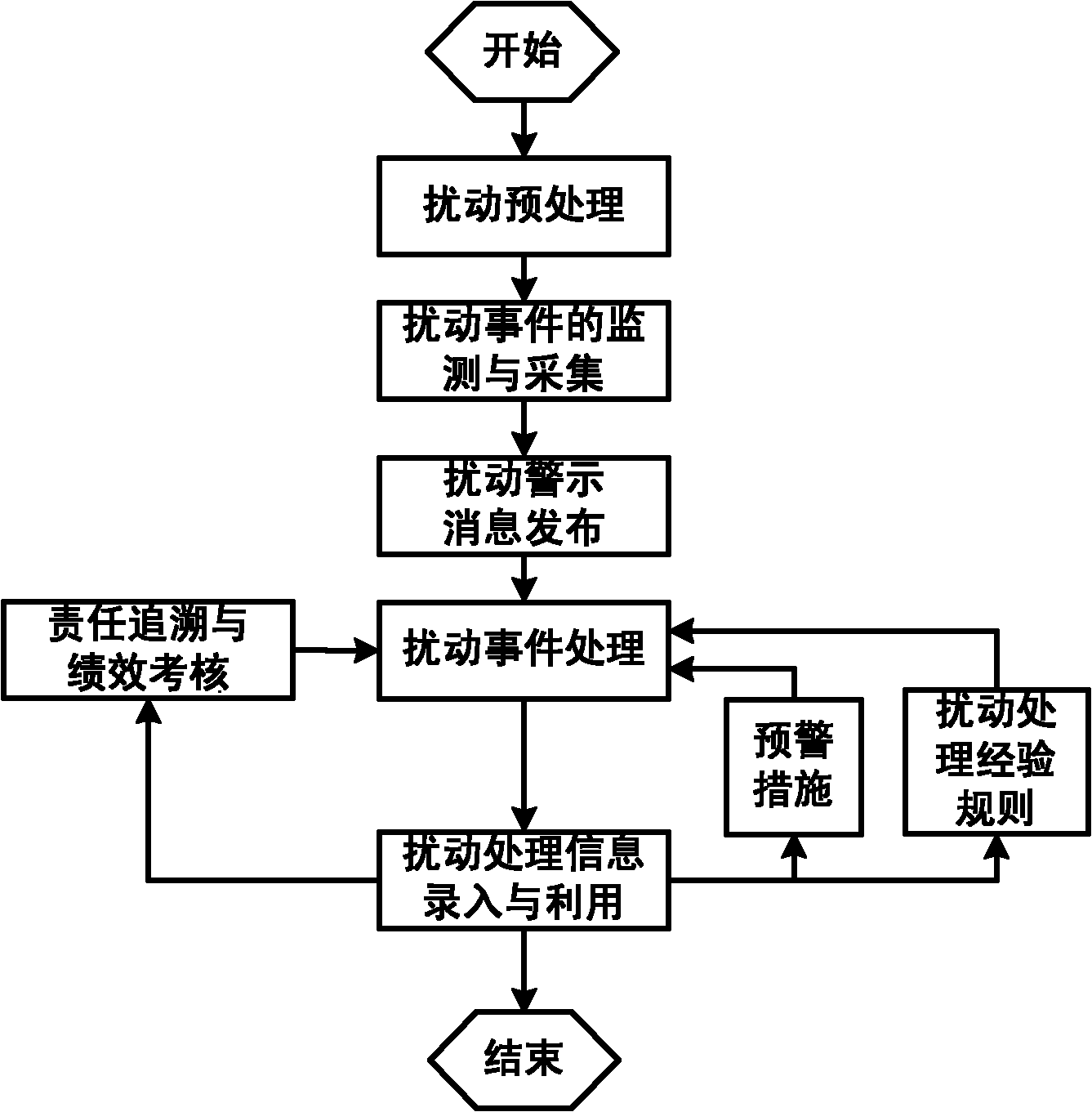

[0028] A method for realizing the balanced production of a vehicle assembly workshop, comprising the steps of ( figure 1 shown):

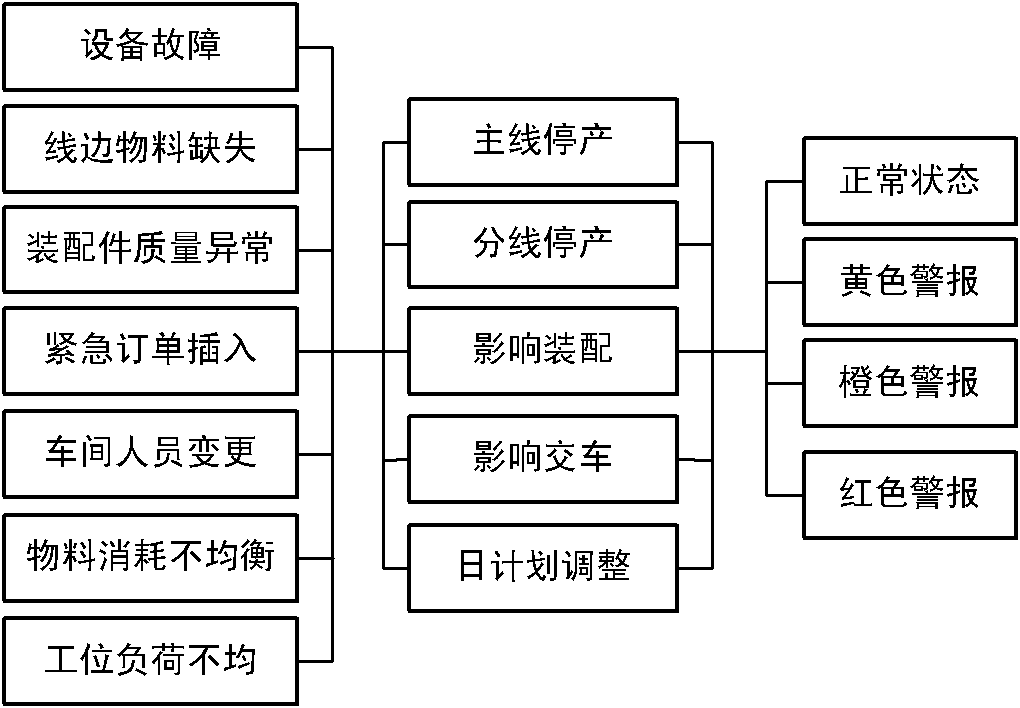

[0029] Step (1) The preprocessing step is to predetermine and classify various common disturbance factors that affect the balanced production in the production operation of the automobile assembly workshop, and determine the corresponding alarm levels of various disturbance factors.

[0030] Predetermine the various disturbance factors that affect the balanced production in the production and operation of the automobile assembly workshop, and then divide the disturbance factors into dominant disturbances and recessive disturbances according to the impact intensity of the disturbance factors on the balanced production of the assembly workshop, and determine the The alarm level of the assembly shop deviating from the balanced production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com