Rotary tangential feeding machine

A feeder and thread cutting technology, applied in rotary conveyors, conveyors, transportation and packaging, etc., can solve problems such as rotor failure, motor burnout, shell fragmentation, etc., to ensure normal operation and prolong service life , the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

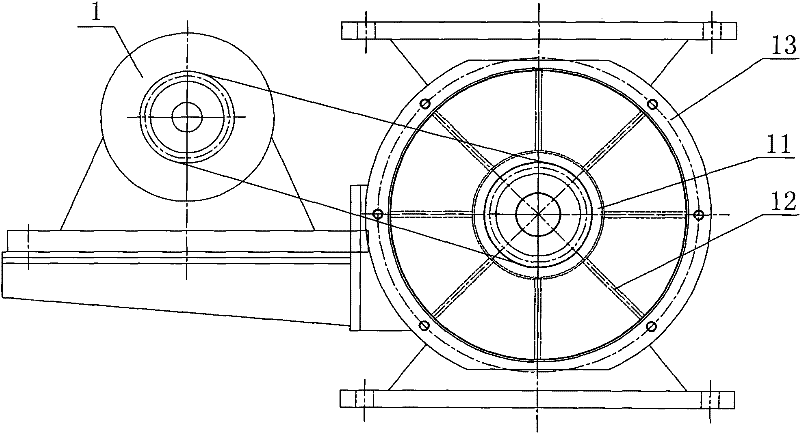

[0019] Rotary valves in the prior art such as figure 2 As shown, it is only suitable for conveying powdery materials and materials with a particle size below 20mm. When bulk materials enter the rotary valve, the material is easily stuck between the casing 13 and the rotor blade 12, causing the rotary valve to fail to rotate and not work properly. , it will cause the motor 1 to burn out or the shell 13 to crack in severe cases.

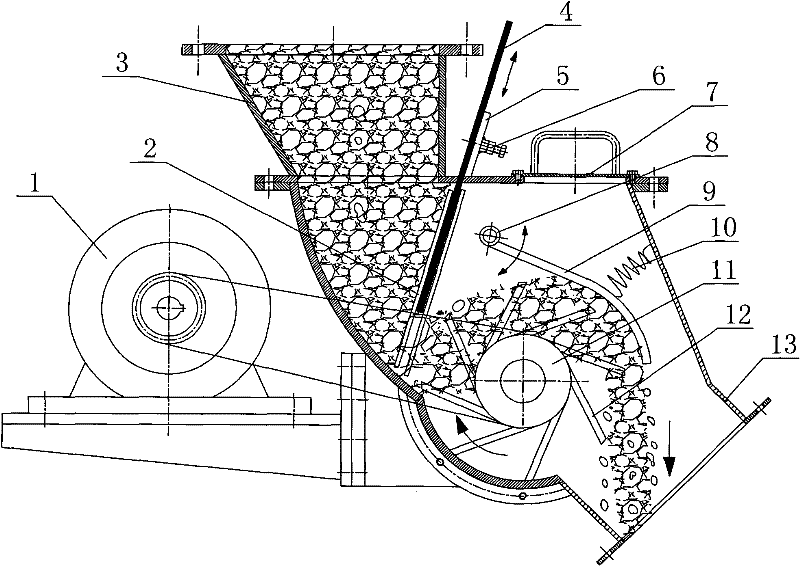

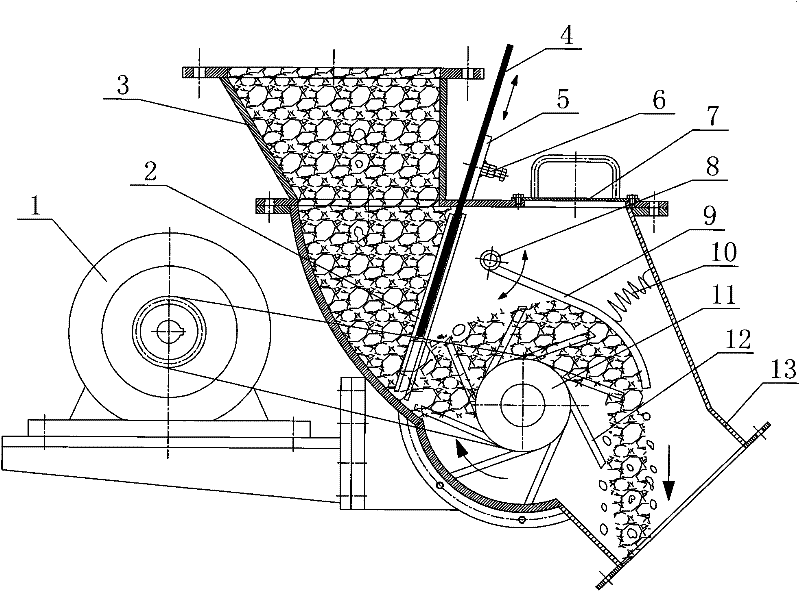

[0020] The present invention improves the feeder, making it suitable for the supply of large particle materials, a rotary tangent feeder, such as figure 1 As shown, it includes a motor 1, a housing 13, a rotor 11, a buffer hopper 3, an arc plate 9 and a spring 10, a rotor 11 is installed in the housing 13, and blades 12 are installed on the rotor 11, and the blades 12 are arranged along the tangential direction of the rotor 11 , the motor 1 is connected to the rotor 11, the top of the housing 13 communicates with the buffer hopper 3, the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com