PCB receiving machine push rod with adjustable thrust

A technology of PCB board and board receiving machine, which is applied in the direction of stacking receiving device, electrical components, and printed circuit manufacturing. Board, improve labor productivity, low cost of transformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

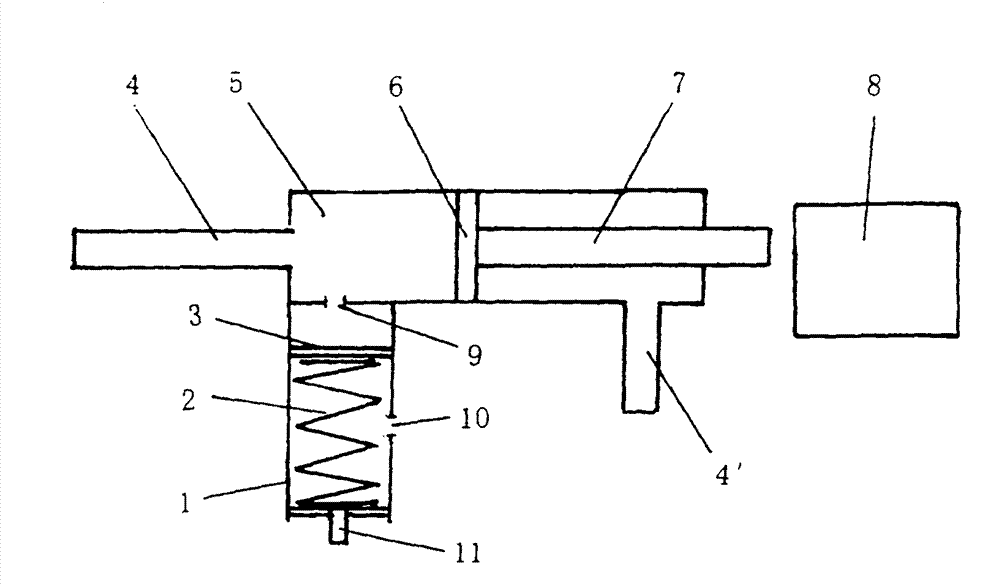

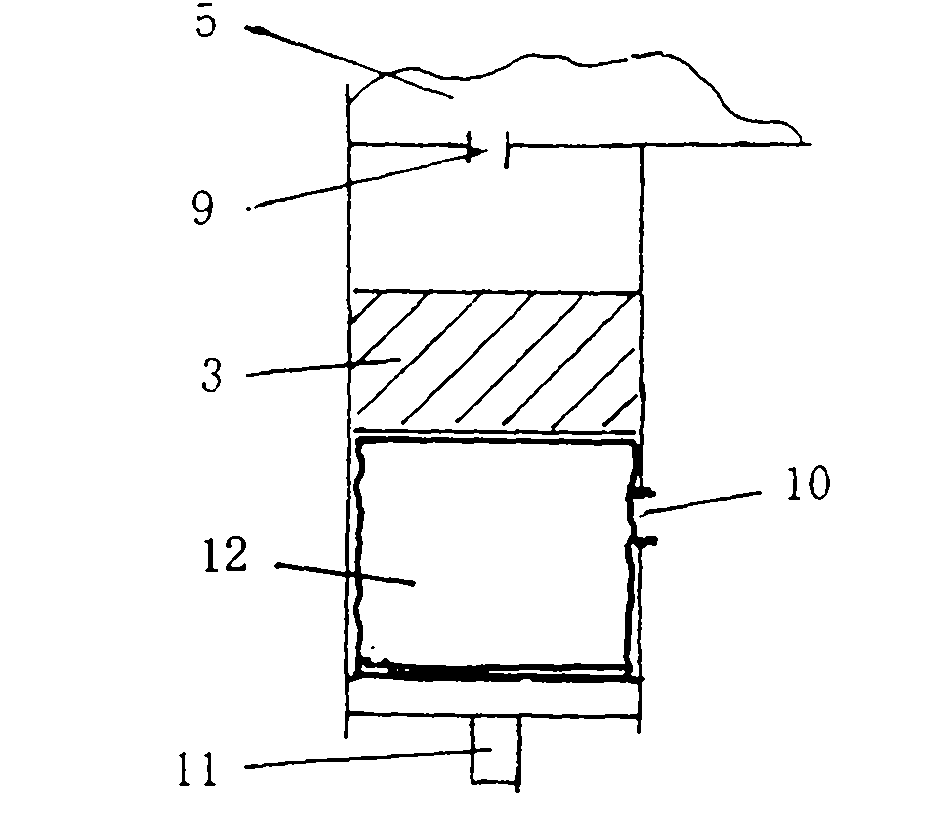

[0014] Such as figure 1 and figure 2 It can be seen from the structural schematic diagram that an adjustable thrust push rod of a PCB board receiving machine includes a cylinder 5, an air supply pipe 4 and an air supply pipe 4', and a push rod 7 connected to the piston 6 placed in the cylinder 5, which is characterized in that : The cylinder 5 is connected to the pressure controller 1, and the gas path is communicated through the air hole 9, the pressure controller 1 has a built-in second piston 3, and the second piston 3 is connected to the bottom of the pressure controller 1 The wall of the pressure controller 1 is provided with an exhaust hole 10 .

[0015] A pressure regulating knob 11 is arranged at the bottom of the pressure controller 1 .

[0016] A spring 2 is placed between the second piston 3 and the pressure regulating knob 11 .

[0017] Or the second piston 3 and the bottom of the pressure controller 1 are provided with magnetic steel or magnetic force coils fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com