Non-rust electroplating process

An electroplating process and process technology, applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of electroplating environmental pollution, pollution, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

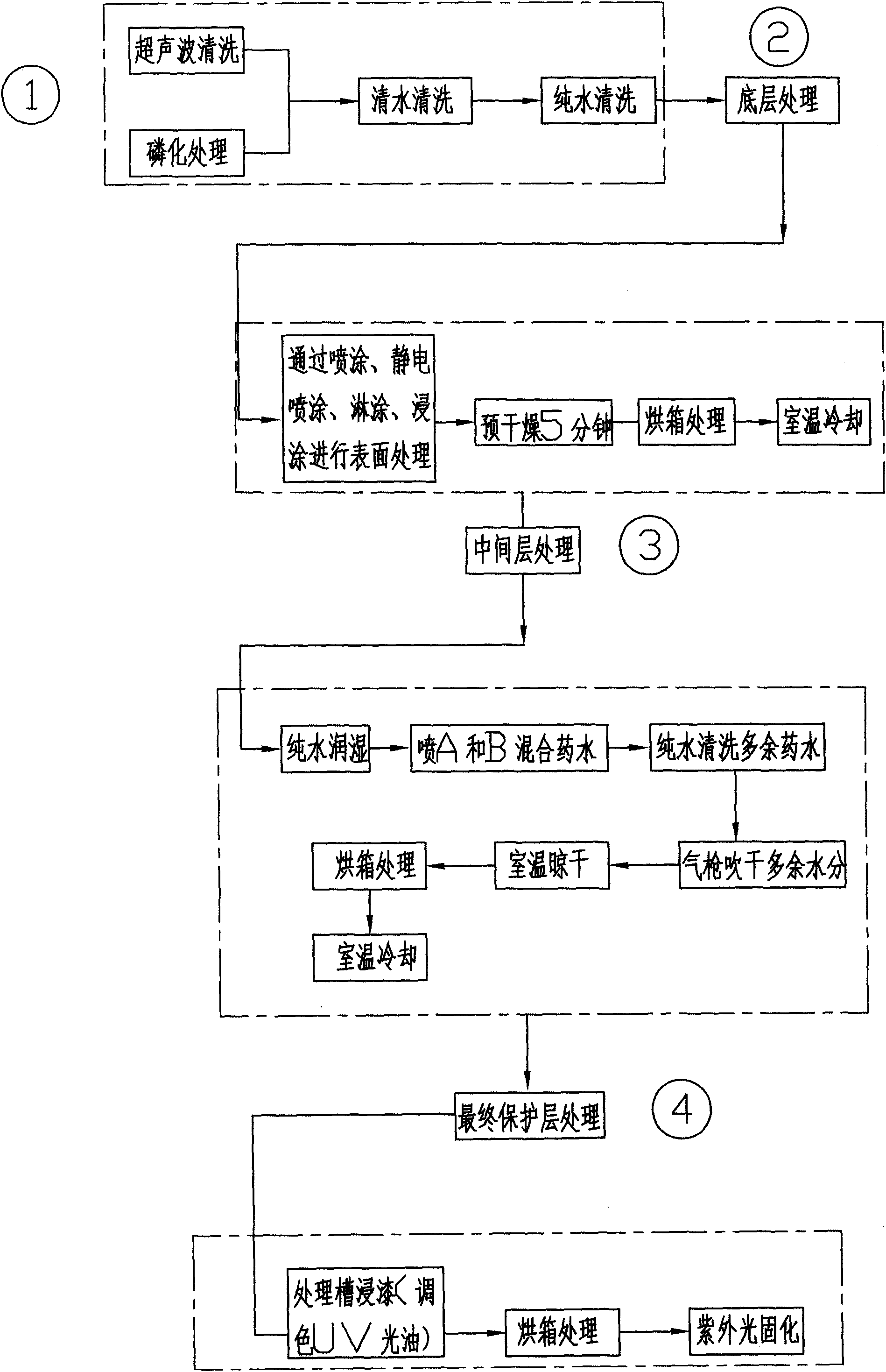

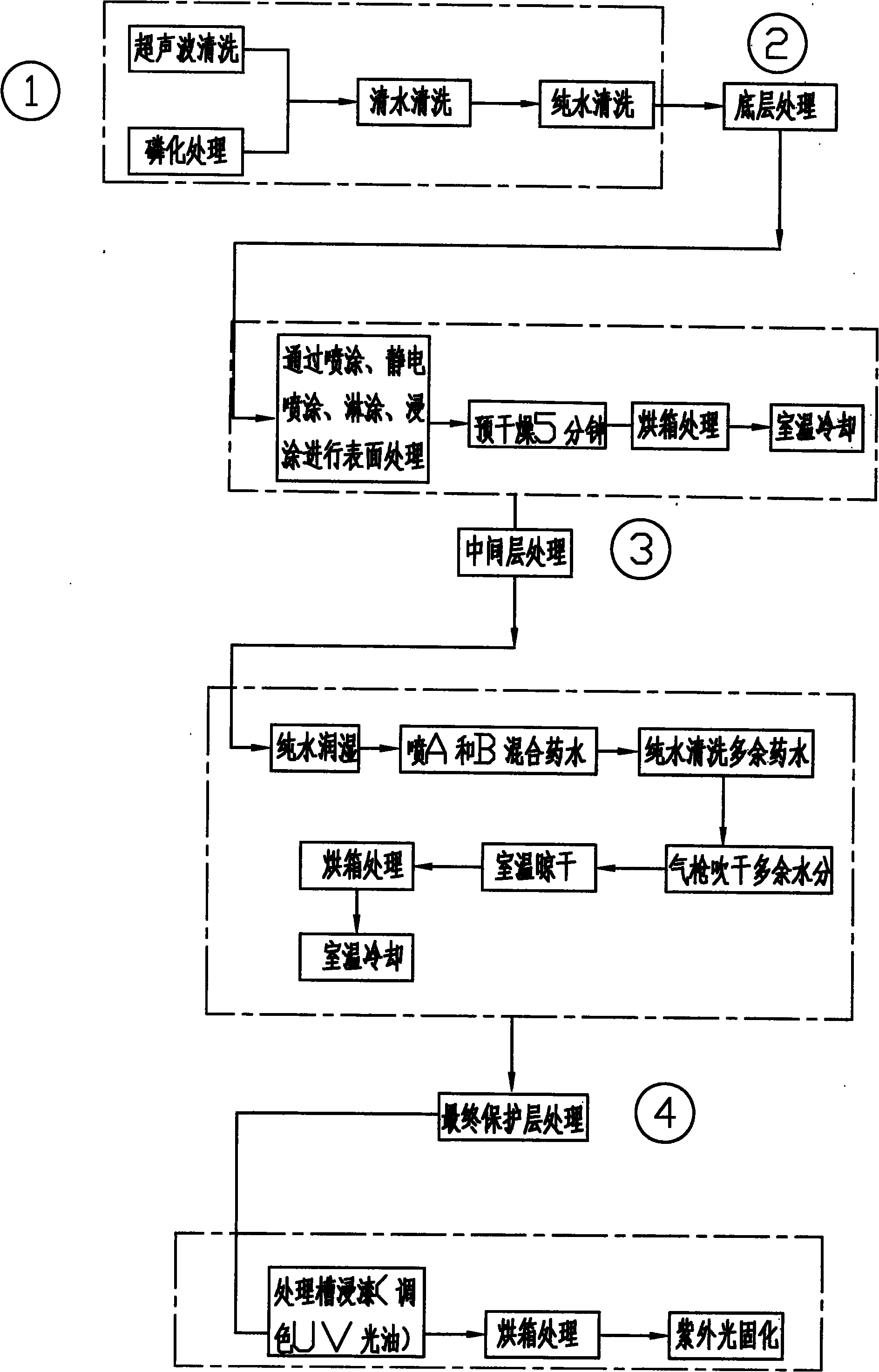

[0021] Example 1: Process flow of stainless electroplating

[0022] 1) Clean the product: put the product on a special hanger and clean it with ultrasonic waves a. Configure the cleaning solution. b. Heating the cleaning liquid to improve the cleaning effect (using environmentally friendly steam heating) the product is installed on the hanger and cleaned directly. c. Turn on the ultrasonic wave for 1 minute vibration treatment. d. Then wash it twice in clean water. Wash it once in pure water with conductivity ≤0.1μS. (Phosphating treatment is also required for steel products)

[0023] 2) Bottom treatment: a. Dilute the transparent or non-transparent paint with high brightness. b. Install the product on the hanger and then use spraying, electrostatic spraying, shower coating, dip coating and other methods for surface treatment. The construction temperature should not be greater than 8% relative to the temperature above 5°C. c. After surface treatment, pre-dry at room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com