POM/PET alloy material and preparation method thereof

An alloy material, POM55% technology, applied in the field of POM/PET alloy material and its preparation, can solve the problem of short service life, achieve the effect of low shrinkage, high impact resistance, and increase impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

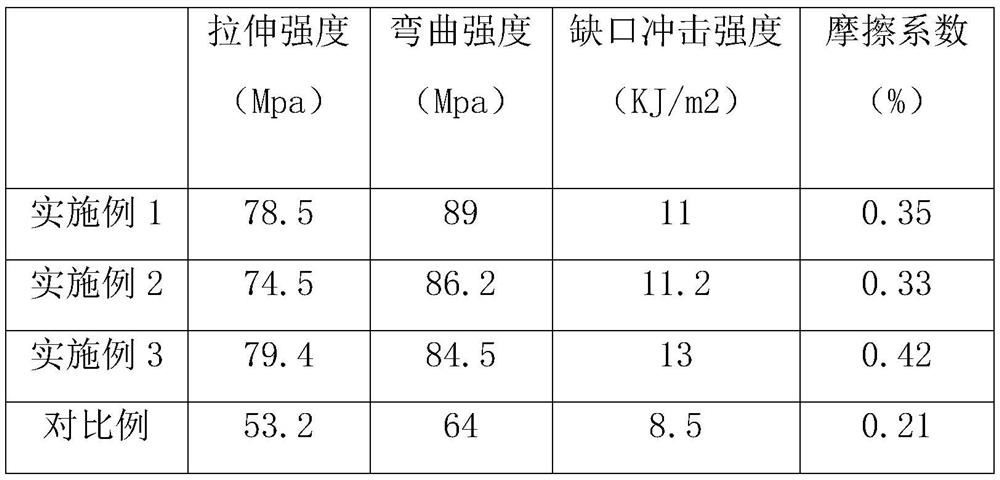

Examples

Embodiment 1

[0015] The POM / PET alloy material of this embodiment is composed of the following components by weight fraction: POM55%; PET15%; blending agent 5%; phase solvent 3%; antioxidant 0.5%; Chain agent 0.1; coupling agent 0.1%.

[0016] A kind of preparation method of POM / PET alloy material, comprises the steps:

[0017] S1. Add POM, PET, blending agent, phase solvent, antioxidant, formaldehyde absorbent, chain extender and coupling agent to the high-speed mixer for high-speed pre-mixing according to the above weight fraction components;

[0018] S2. Take the mixture obtained in step S1 and add it from the feeding port of the screw extruder, the processing temperature is 160°C, the screw speed is 250r / min, the pressure of the extruder is 10MPa, and then granulated by twin-screw melt extrusion A finished product of POM / PET alloy material is obtained.

Embodiment 2

[0020] The POM / PET alloy material of this embodiment is composed of the following components by weight fraction: POM75%; PET25%; blending agent 17%; phase solvent 5%; antioxidant 1%; formaldehyde absorbent 0.7%; Chain agent 0.3%; coupling agent 0.3%.

[0021] A kind of preparation method of POM / PET alloy material, comprises the steps:

[0022] S1. Add POM, PET, blending agent, phase solvent, antioxidant, formaldehyde absorbent, chain extender and coupling agent to the high-speed mixer for high-speed pre-mixing according to the above weight fraction components;

[0023] S2. Take the mixture obtained in step S1 and add it from the feeding port of the screw extruder, the processing temperature is 180°C, the screw speed is 300r / min, the pressure of the extruder is 13MPa, and then granulated by twin-screw melt extrusion Obtain POM / PET alloy material finished product 2.

Embodiment 3

[0025] The POM / PET alloy material of this embodiment is composed of the following components by weight fraction: POM90%; PET40%; blending agent 20%; phase solvent 7%; antioxidant 2%; Chain agent 0.6%; coupling agent 0.5%.

[0026] A kind of preparation method of POM / PET alloy material, comprises the steps:

[0027] S1. Add POM, PET, blending agent, phase solvent, antioxidant, formaldehyde absorbent, chain extender and coupling agent to the high-speed mixer for high-speed pre-mixing according to the above weight fraction components;

[0028] S2. Take the mixture obtained in step S1 and add it from the feeding port of the screw extruder, the processing temperature is 200°C, the screw speed is 350r / min, the pressure of the extruder is 15MPa, and then granulated by twin-screw melt extrusion Obtain POM / PET alloy material finished product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com