Reinforced concrete frame node

A technology of reinforced concrete and reinforced concrete beams, which is applied to building components, floor slabs, buildings, etc., can solve the problems of difficult cross-sectional size and longitudinal reinforcement ratio, and achieve the effect of preventing continuous collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

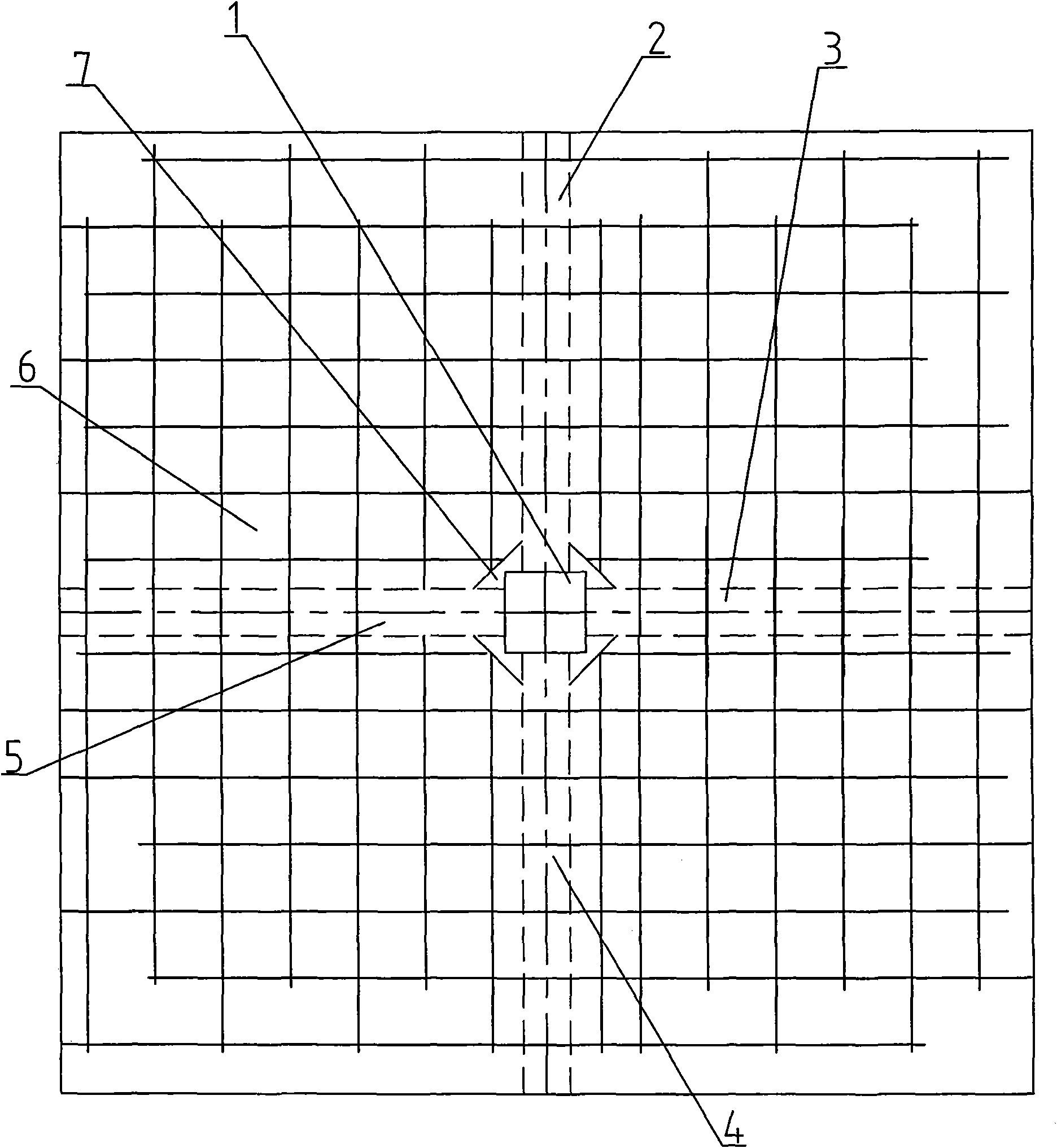

[0019] A reinforced concrete frame joint, see attached figure 1 , in the figure, a reinforced concrete column 1, a first reinforced concrete beam 2, a second reinforced concrete beam 3, a third reinforced concrete beam 4, a fourth reinforced concrete beam 5, a reinforced concrete floor 6, and a corner joint 7.

[0020] The reinforced concrete floor 6 around the intersection of the reinforced concrete column 1 and the reinforced concrete beam is provided with open angle joints 7 on the steel bars, and the open angle joints 7 are broken with the steel bars at the intersection of the reinforced concrete column 1 and the reinforced concrete beam. open state.

[0021] In this embodiment, the intersection points between the reinforced concrete column 1 and the first reinforced concrete beam 2, the second reinforced concrete beam 3, the third reinforced concrete beam 4 and the fourth reinforced concrete beam 5 are in the shape of a "cross" cross structure, and The corner joint 7 is ...

Embodiment 2

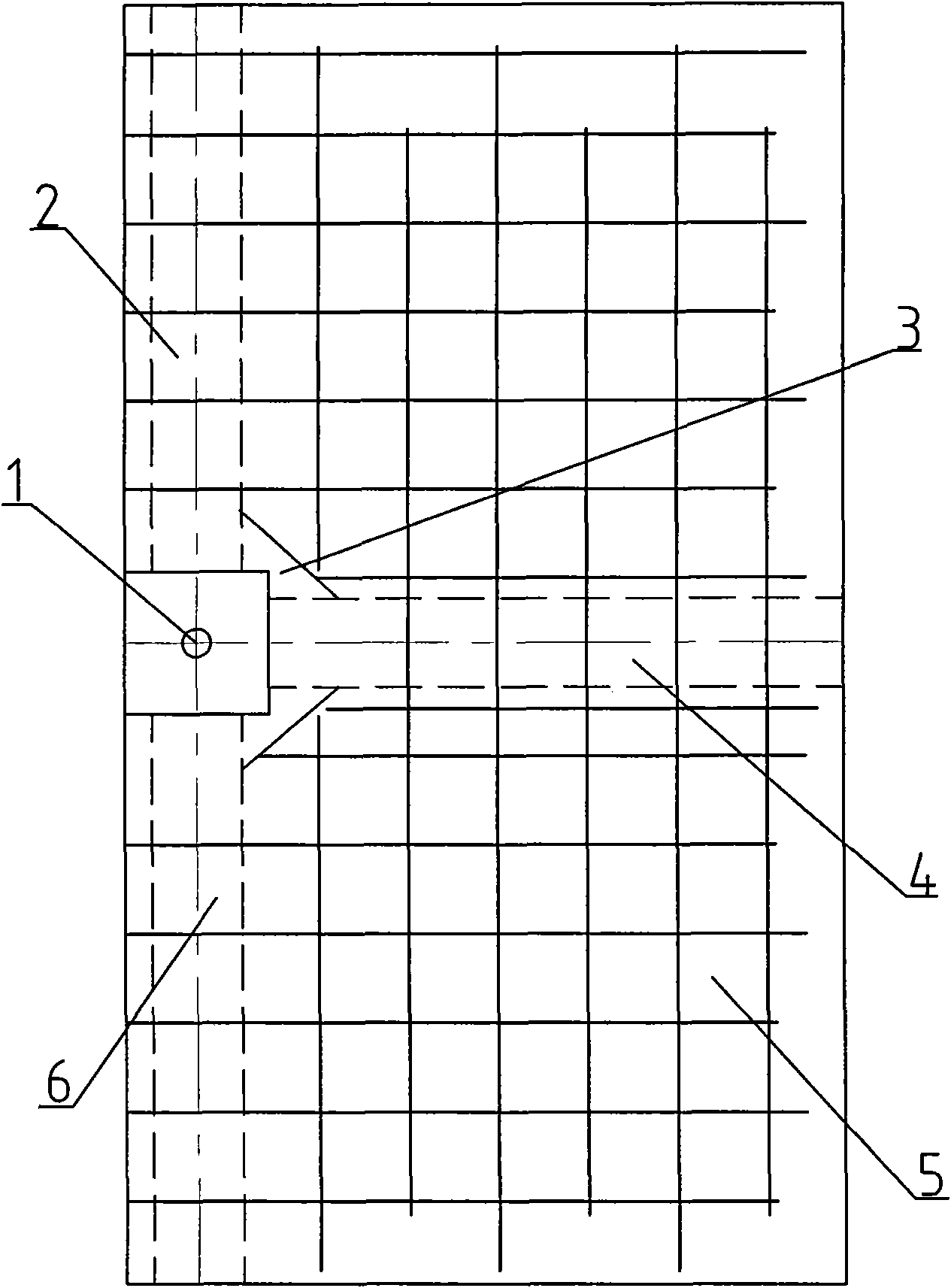

[0026] A reinforced concrete frame joint, see attached figure 2 , in the figure: reinforced concrete column 1, first reinforced concrete beam 2, open angle joint 3, second reinforced concrete beam 4, reinforced concrete floor slab 5, third reinforced concrete beam 6.

[0027] The reinforced concrete floor slab 5 around the intersection of the reinforced concrete column 1 and the reinforced concrete beam is provided with open angle joints 3 on the steel bars, and the open angle joints 3 are broken with the steel bars at the intersection of the reinforced concrete column 1 and the reinforced concrete beam. open state.

[0028] In this embodiment, the intersection of the reinforced concrete column 1 and the first reinforced concrete beam 2, the second reinforced concrete beam 4 and the third reinforced concrete beam 6 is a "T" cross structure, and the open angle joint 3 is placed in the intersecting reinforced concrete beam. Between the angles between the beams; that is: the re...

Embodiment 3

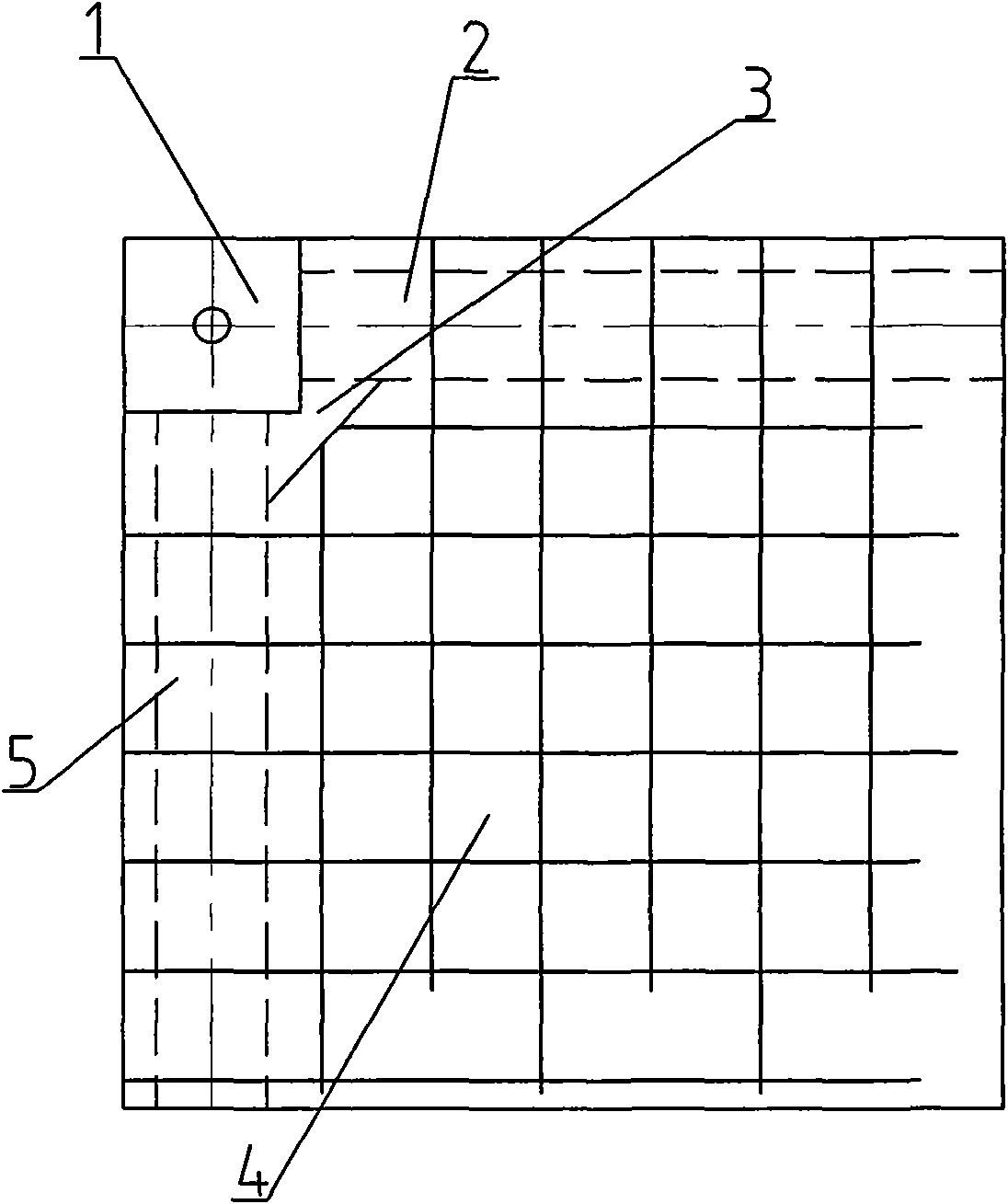

[0033] A reinforced concrete frame joint, see attached image 3 , in the figure: reinforced concrete column 1, first reinforced concrete beam 2, corner joint 3, reinforced concrete floor slab 4, second reinforced concrete beam 5.

[0034] In this embodiment, the reinforced concrete column 1 is located at the intersection of two reinforced concrete beams, that is, as image 3 As shown, the reinforced concrete column 1 is located at the intersection of the first reinforced concrete beam 2 and the second reinforced concrete beam 5, and the open angle joint 3 is placed in the steel bar between the angle between the first reinforced concrete beam 2 and the second reinforced concrete beam 5 Concrete floor 4 on.

[0035]For the existing cast-in-place reinforced concrete frame structure, cutting equipment can be used to cut the corner joint 3 on site, and the top reinforcement on the reinforced concrete floor 4 at the intersection of the reinforced concrete column 1 and the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com