Fan and guide structure thereof

A fan and airflow technology, which is applied in the field of fans and their guide structures, can solve the problems of high noise, low air volume, and low efficiency, and achieve the effects of protecting circuits, large air volume, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

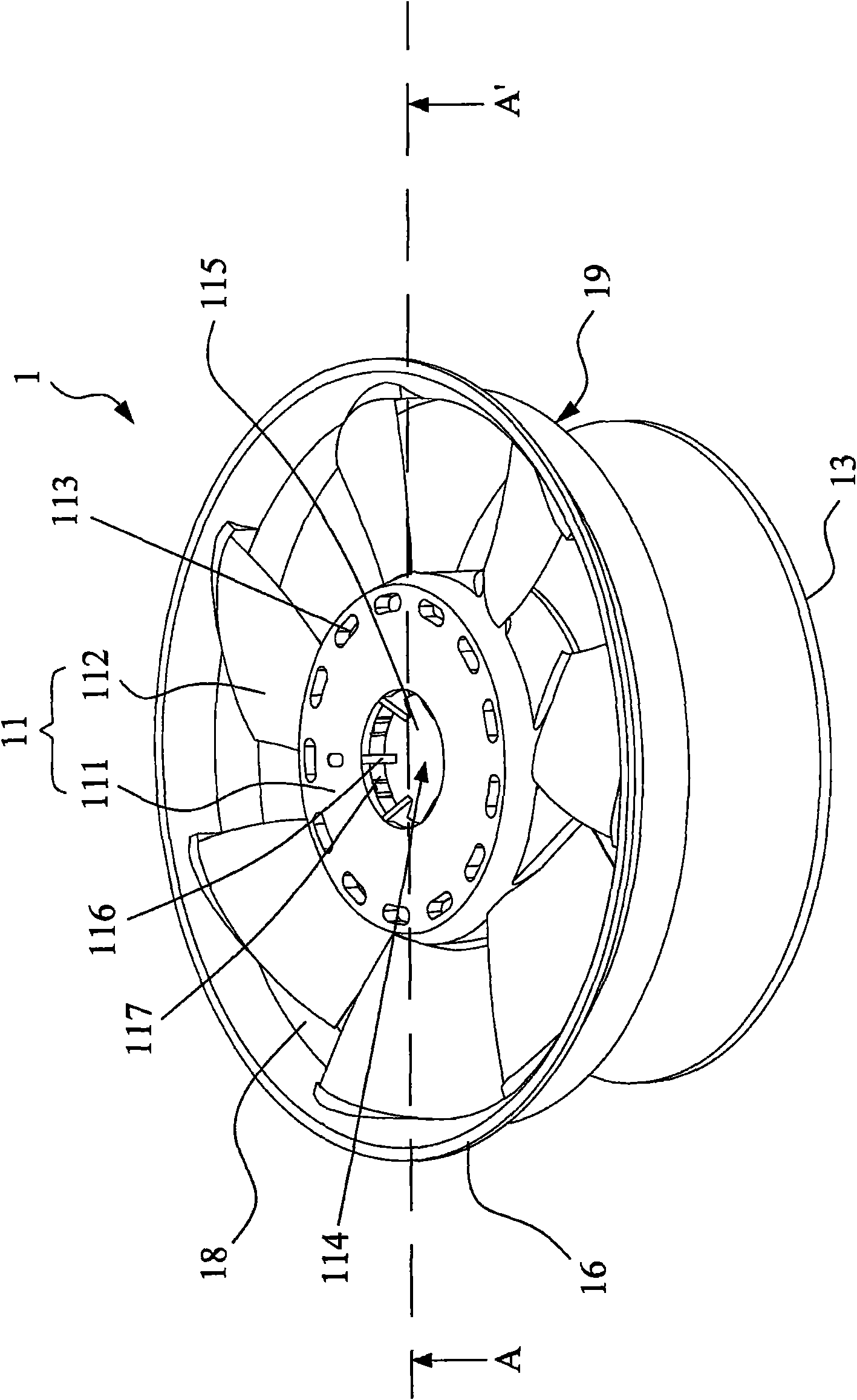

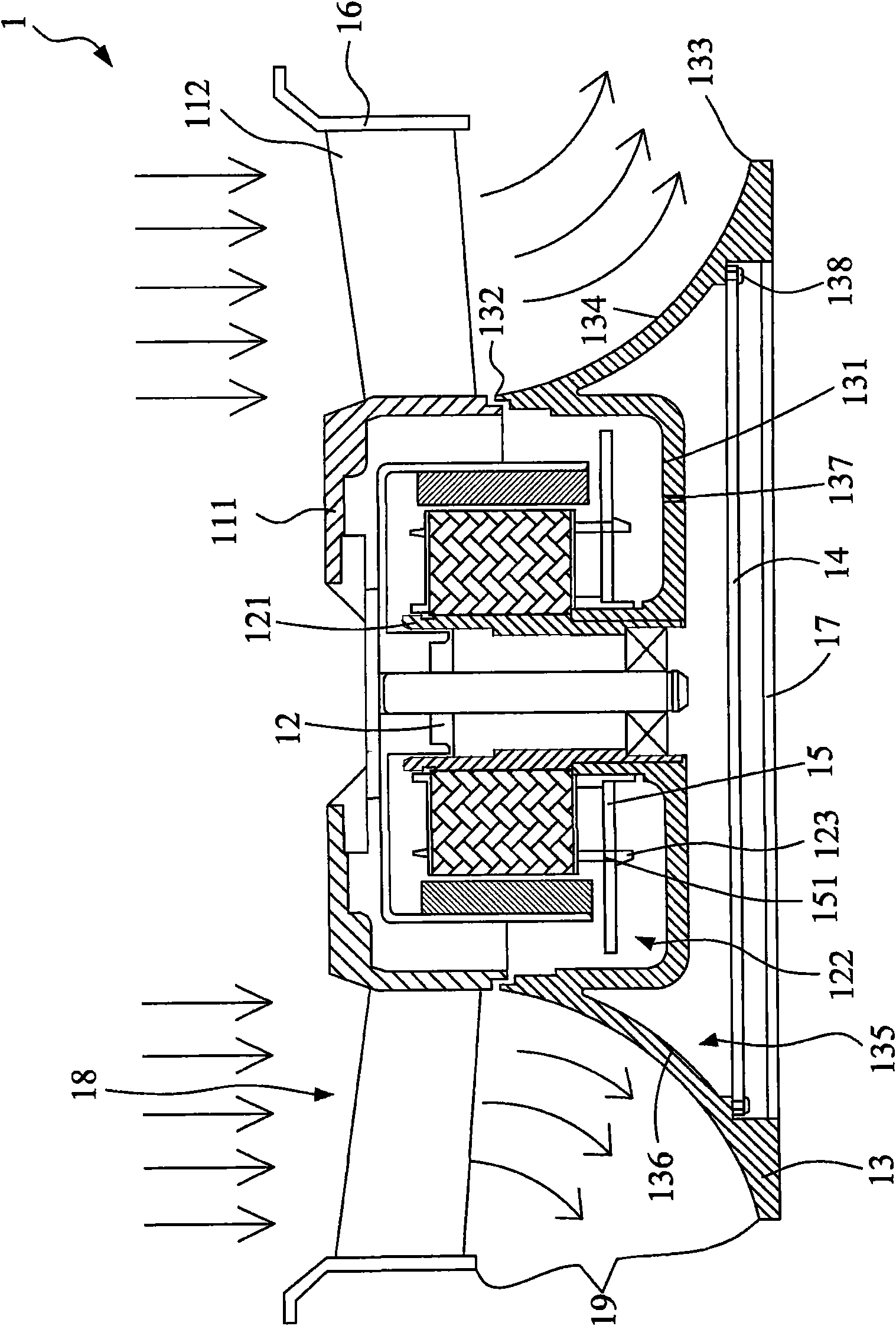

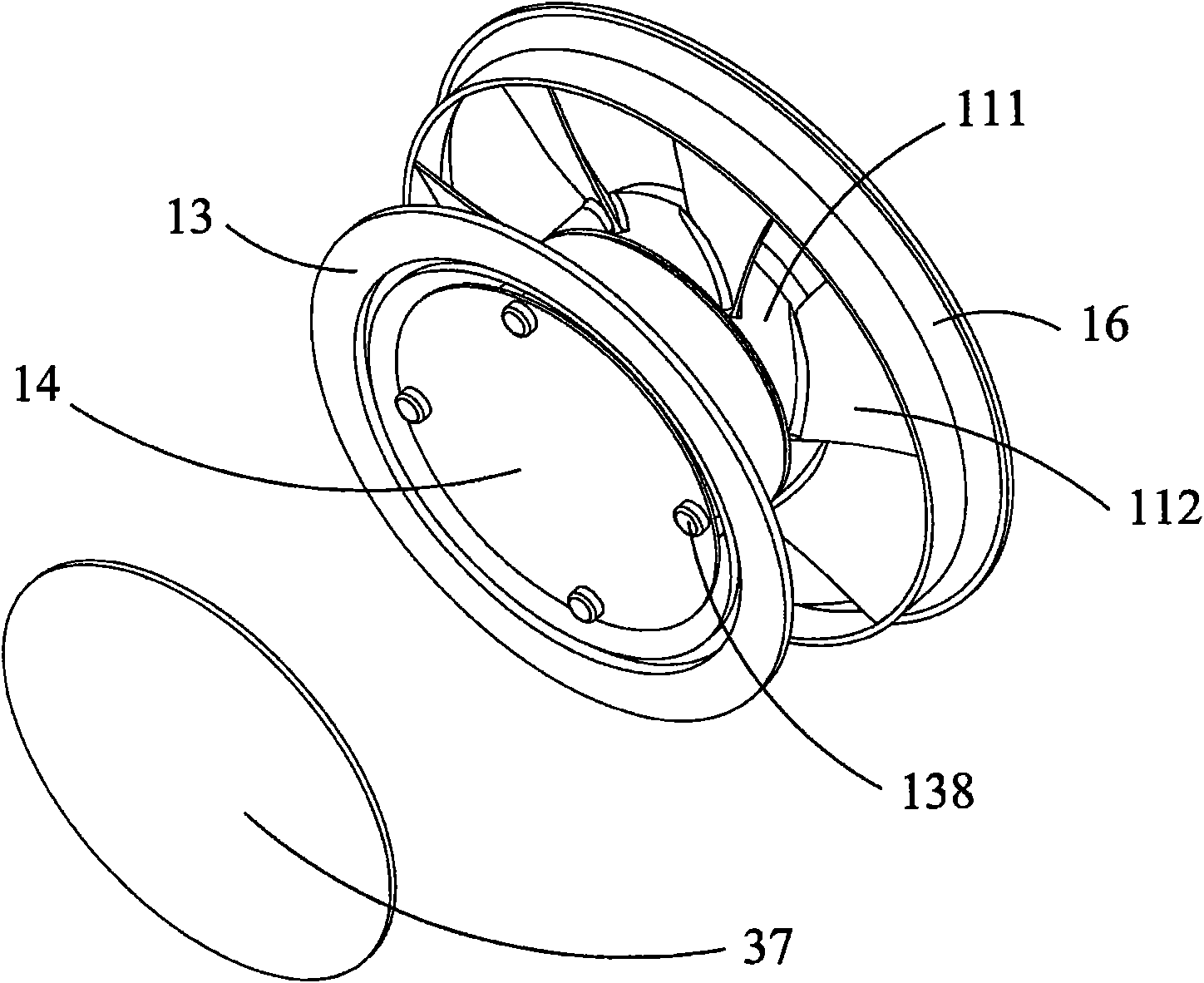

[0029] Please also refer to figure 1 and image 3 As shown, the fan 1 of the present invention can be an axial fan, and includes an impeller 11, a motor 12, a flow guide structure 13, a first circuit device 14, a second circuit device 15, and a guide ring 16. And a cover 17.

[0030] The impeller 11 has a hub 111 and a plurality of fan blades 112. The fan blades 112 are arranged on the outer ring surface of the hub 111, and the motor 12 is connected with the impeller 11 to drive the impeller 11 to rotate. Furthermore, the upper surface of the hub 111 has a plurality of balance holes 113. When the impeller 11 of the fan 1 is unbalanced, the balance hole 113 can be filled with appropriate balance materials according to the shaking state of the impeller 11 to make the fan The impeller 11 of 1 can rotate in a balanced manner without shaking.

[0031] In addition, the center of the hub 111 of the fan 1 has an air inlet groove 114. The inner wall of the air inlet groove 114 is hollowed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com