Automatic control device for forced draught fan

A technology of automatic control devices and blowers, applied in pump control, machine/engine, mechanical equipment, etc., can solve problems such as potential safety hazards, enterprise losses, increased repair and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

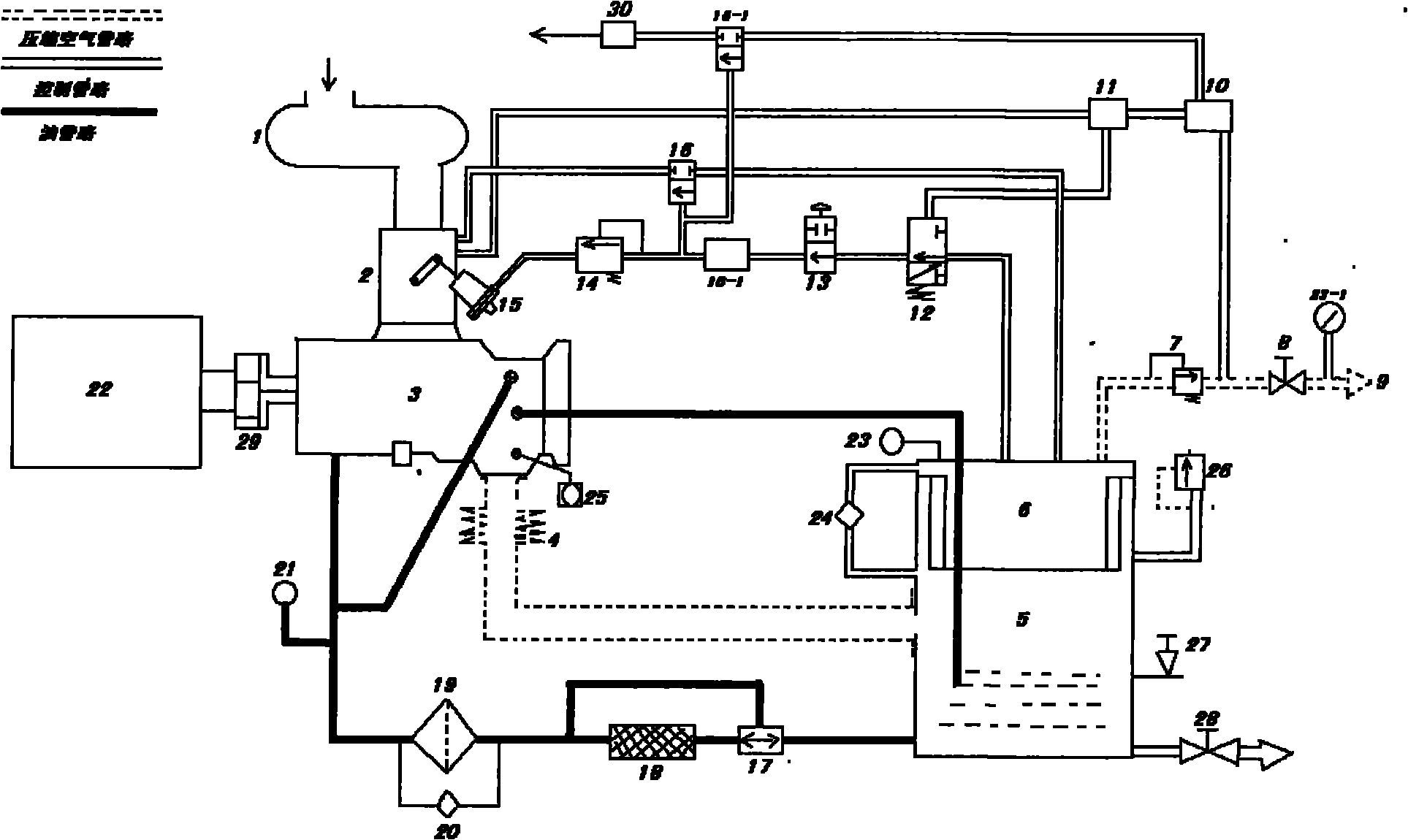

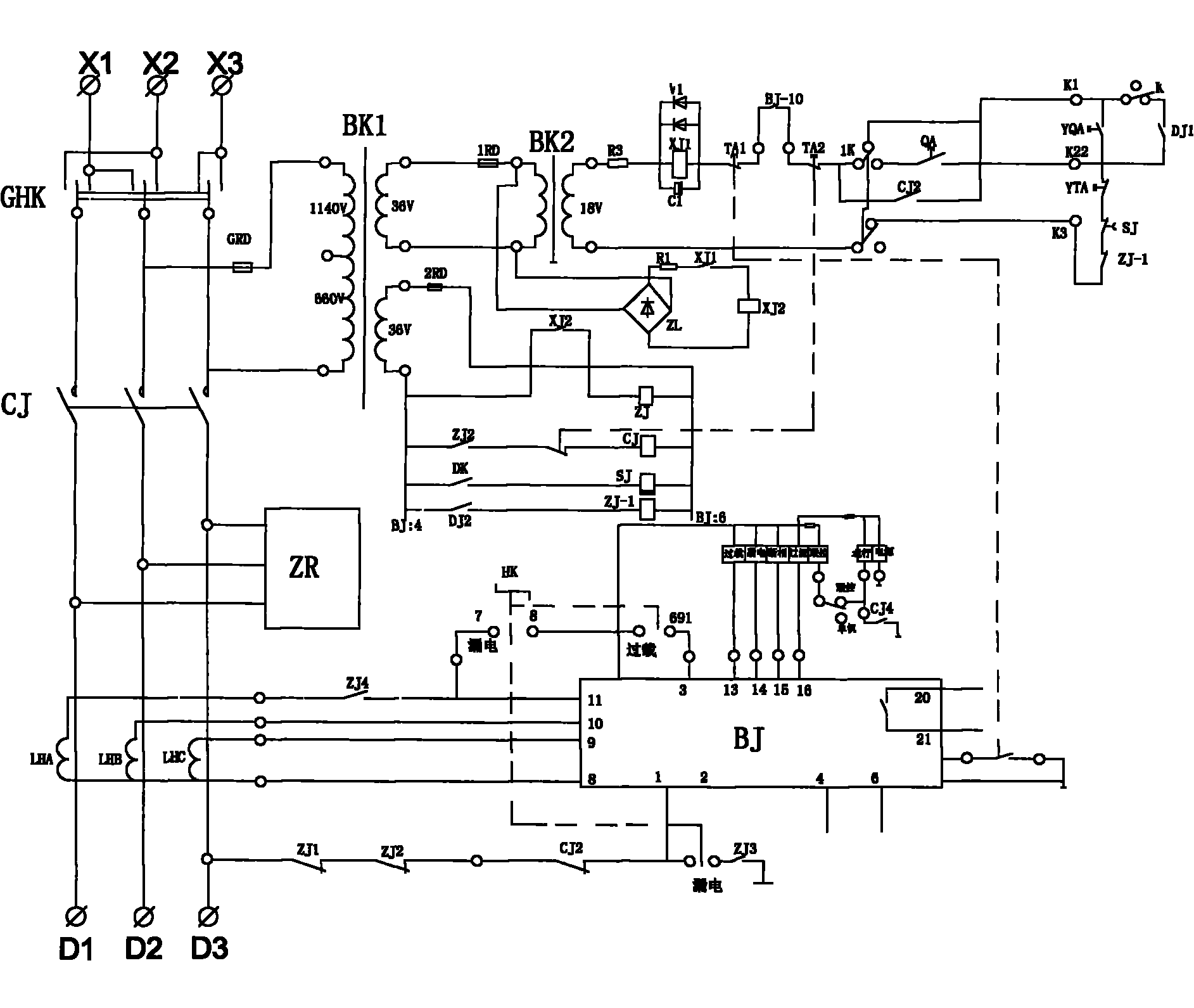

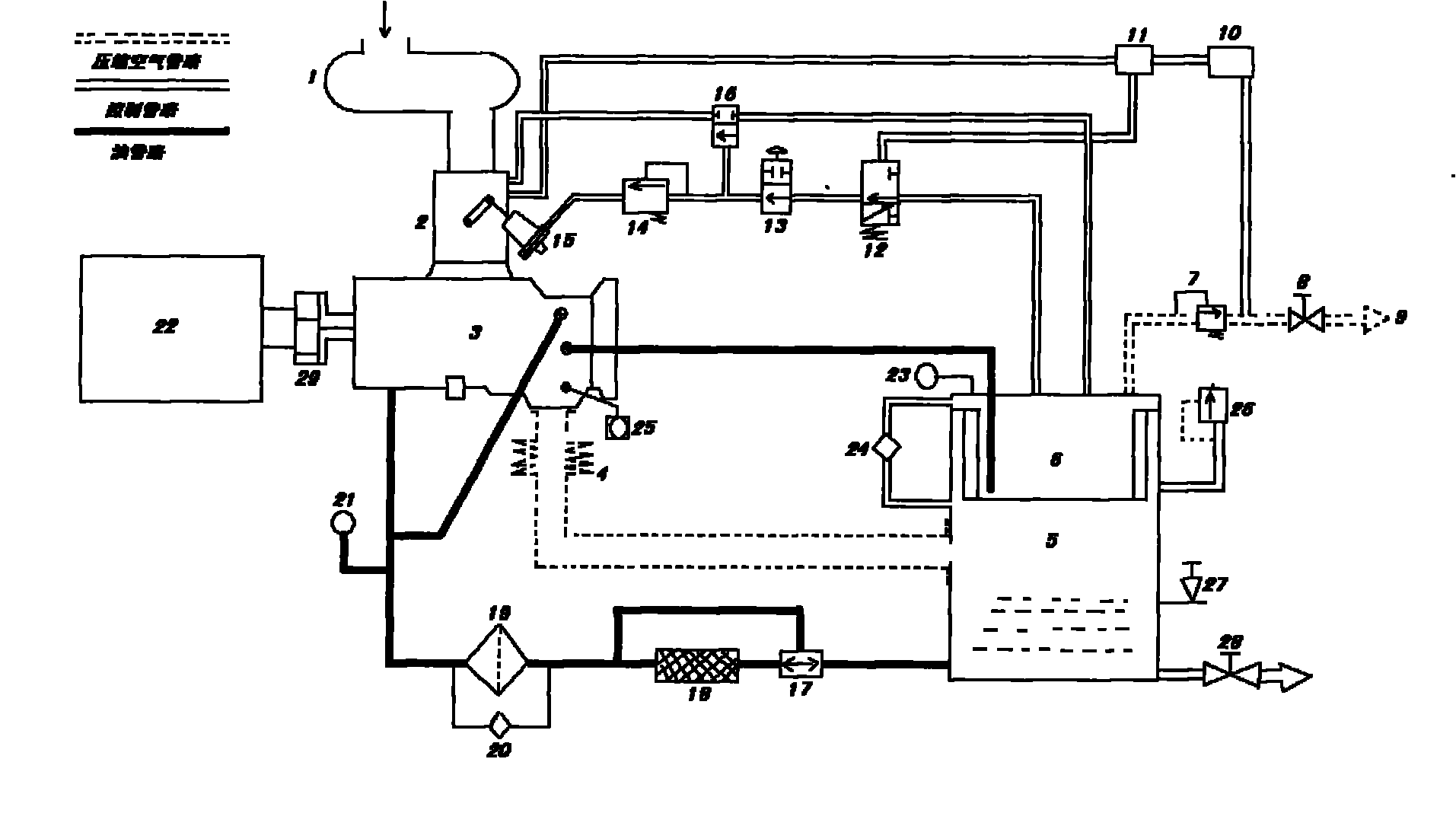

[0041] (1) Basic principle: press the start control button of the compressor, turn on the compressor, and load it manually. During the process of gradually increasing the pressure of the compressor, turn the "manual / automatic" switch of the electrical control of the device to the "automatic" position. When the outlet pressure of the exhaust pipe of the compressor reaches the artificially set "high" pressure value, the pneumatic switch of this device will connect the motor to control the electric stop circuit of the magnetic starter, and the device will automatically stop after a delay. When the pressure of the compressed air system gradually drops to the artificially set self-starting "low" pressure value, after the conversion of the device, the fan is automatically turned on, and the automatic loading is completed, so that the fan operates normally and the system pressure continues to rise. When the system pressure rises and reaches the artificially set "high" pressure value, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com