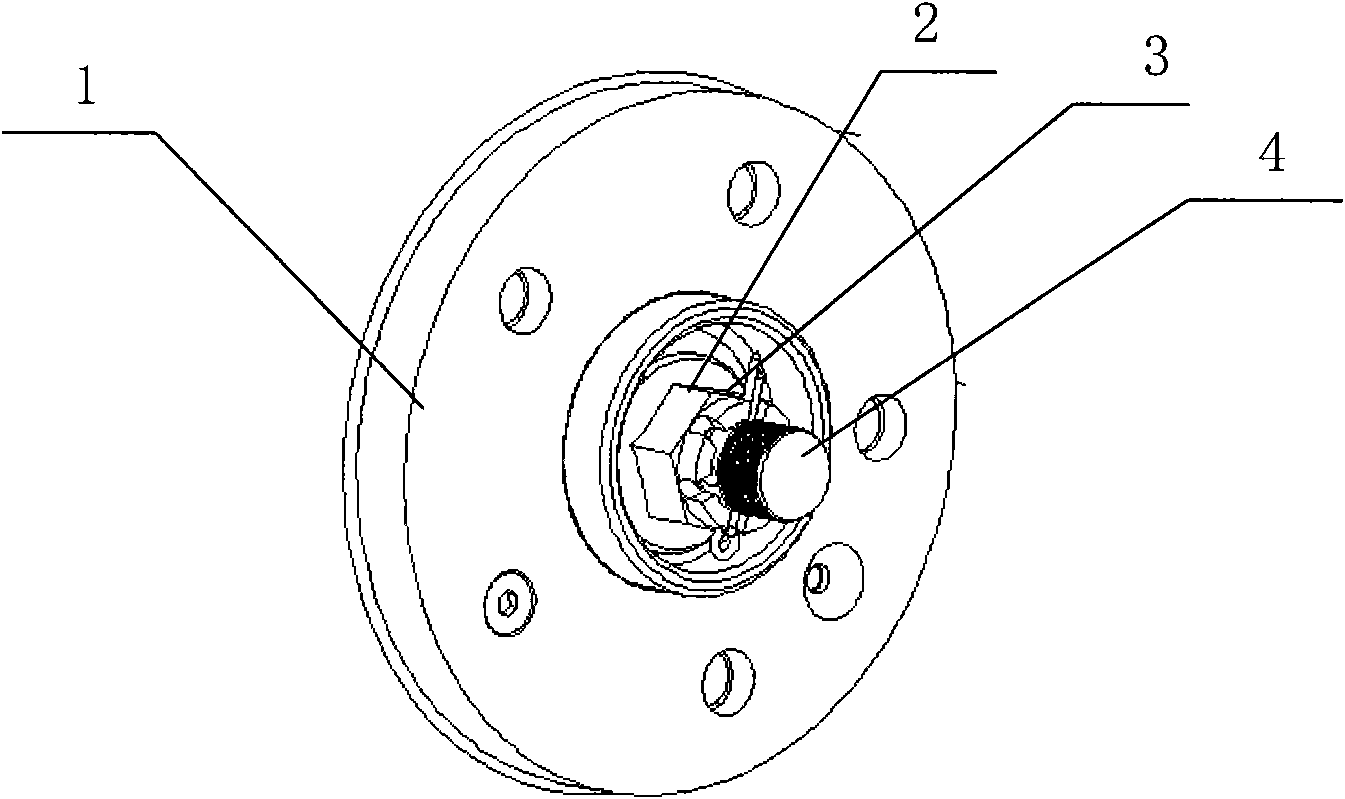

Structure for locking wheel locking nut and drive shaft

A drive shaft and dead nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of damaging the brake 1 bearing, failing to meet the torque requirements of locked wheels and drive shafts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

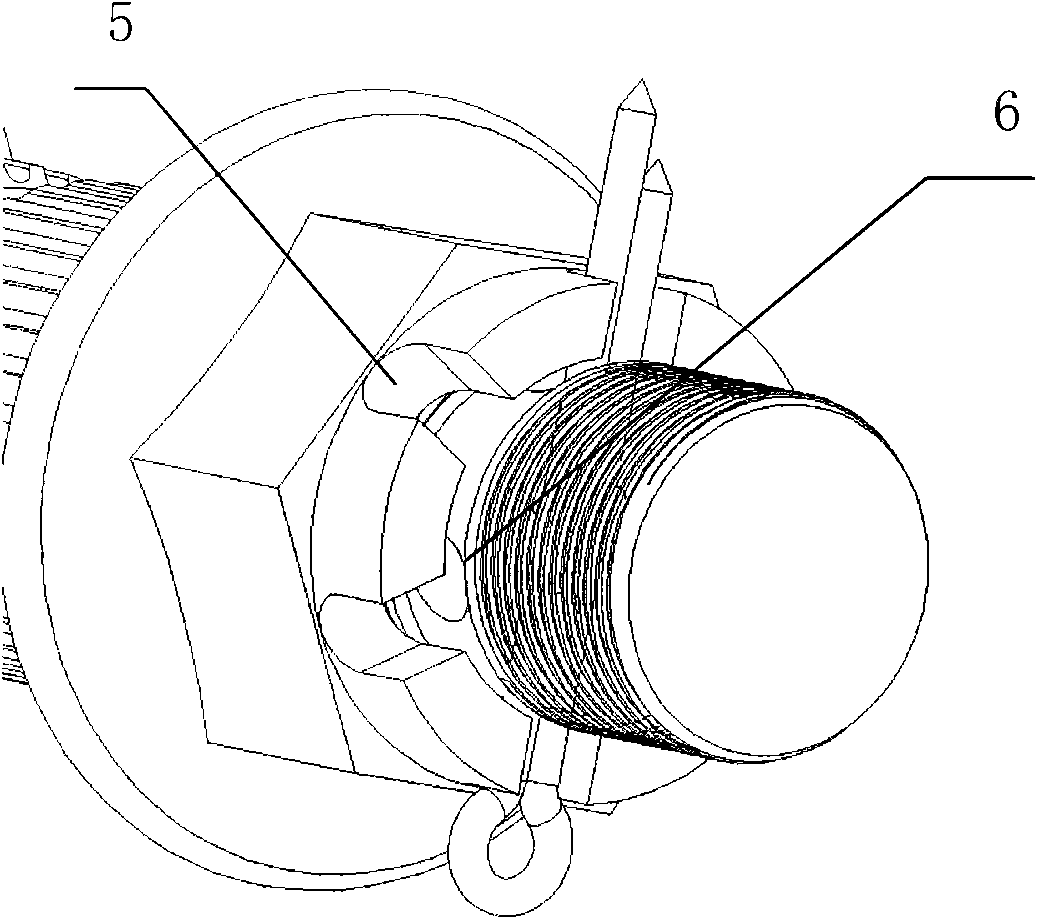

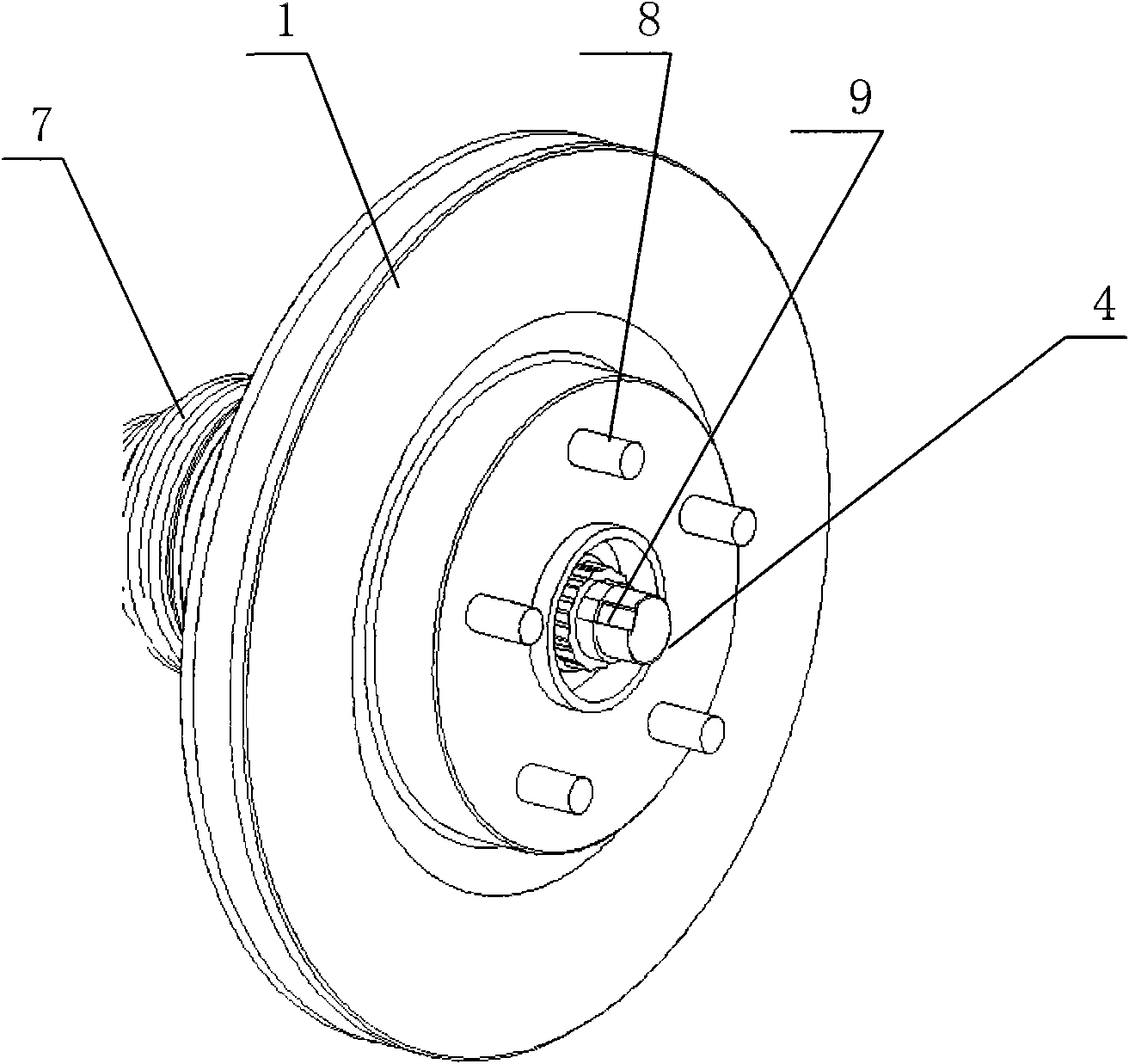

[0013] see Figure 5 The locking structure of the wheel lock nut and the drive shaft proposed by the present invention mainly improves the structure of the lock nut 9 . The outer peripheral surface of the wheel locknut is designed to be divided into three sections by three steps, the bottom section is a disc washer end 91, the middle section is a polygonal cylindrical body 92, and the upper section is a locking edge 93 . Correspondingly, the drive shaft 4 also needs to be improved a bit, and a section of inclined groove 41 is cut on the outer peripheral surface of the drive shaft 4 near the end.

[0014] see image 3 and Figure 4 , in the assembly process, assemble the lock nut 9 on the drive shaft 4, when the torque required for lock is reached, just knock down the lock nut edge 93 until it is in contact with the drive shaft 4 The chute 41 is close to each other, so that the knocked-off locking edge 93 cooperates with the chute 93 at the end of the drive shaft, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com