A kind of preparation method of ceramic copper clad laminate

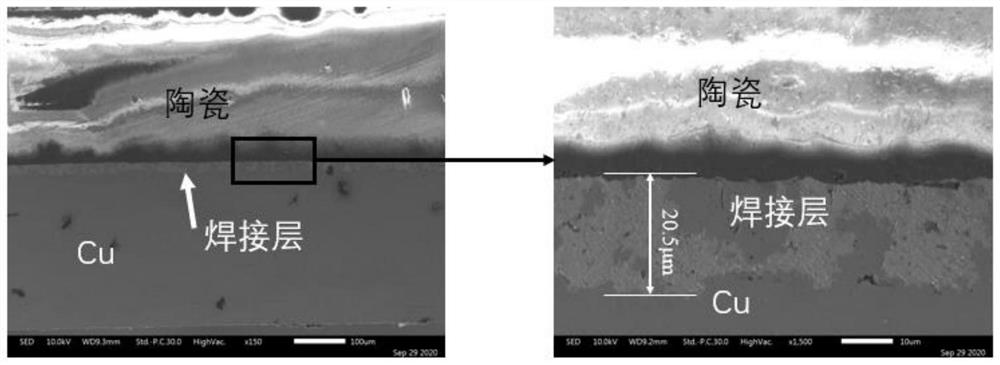

A technology of ceramic copper clad laminate and ceramic substrate, used in chemical instruments and methods, metal layered products, layered products, etc., can solve the problem of unreliable connection between ceramics and copper foil, holes in the welding layer, low thermal cycle life, etc. problem, to achieve the effect of reducing porosity, reducing sintering temperature, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of a ceramic copper clad laminate of the present invention comprises the following steps:

[0023] (1) Active metal solder composition design, vacuum high-pressure gas atomization, powder sieving: After powdering the active metal solder, sieve the powder to obtain an active metal solder powder with a particle size of 5 μm-20 μm; the components of the active metal solder Its mass percentage is: Cu21%-24%, Sn 5%-10%, In 5%-10%, Ti 3%-5%, the balance is Ag, and the proportion of alloy; wherein, the purity of Cu is greater than 99.99wt%, the purity of Sn is greater than 99.99wt%, the purity of In is greater than 99.99wt%, the purity of Ti is greater than 99.99wt%, and the purity of Ag is greater than 99.99wt%. The active metal solder is pulverized by vacuum high-pressure gas atomization. The process conditions of vacuum high-pressure gas atomization are: the vacuum degree of the pulverizing equipment is raised to higher than 1×10 -1 Pa, then heat the a...

Embodiment 1

[0030]The active metal solder is vacuum cast, and the components and mass percentages of the active metal solder are: Cu22.5%, In10%, Sn 5%, Ti 4.5%, and the balance is Ag. The purity of each metal is higher than 99.99wt%; raise the vacuum degree of the milling equipment to higher than 1×10 -2 Pa, then the active metal solder was heated to 1000°C, and after reaching the temperature, the temperature was maintained for 20min.

[0031] Then carry out vacuum high pressure gas atomization powder, the atomization temperature is 1100 ℃, and the atomization gas flow rate is 35m 3 / min, the melt flow rate of the active metal solder is 9.0 kg / min, and the atomizing gas pressure is 0.8 MPa to obtain alloy powder. Using an ultrasonic vibration sieve powder machine, sieve out the active metal solder powder with a particle size of 5μm-20μm.

[0032] According to the weight percentage, take 42% terpineol, 28% diethylene glycol monobutyl ether, 10% polyethanol 2000, 10% modified hydrogenate...

Embodiment 2

[0038] The active metal solder is vacuum casted. The components and mass percentage of the active metal solder are: Cu21.5%, In10%, Sn 10%, Ti 4%, and the balance is Ag. The purity of each metal is higher than 99.99wt%; raise the vacuum degree of the milling equipment to higher than 1×10 -2 Pa, then the active metal solder was heated to 1000°C, and after reaching the temperature, the temperature was maintained for 20min.

[0039] Then carry out vacuum high pressure gas atomization powder, the atomization temperature is 1100 ℃, and the atomization gas flow rate is 35m 3 / min, the melt flow rate of the active metal solder is 9.0 kg / min, and the atomizing gas pressure is 0.8 MPa to obtain alloy powder. Using an ultrasonic vibration sieve powder machine, sieve out the active metal solder powder with a particle size of 5μm-20μm.

[0040] According to the weight percentage, take 42% terpineol, 28% diethylene glycol monobutyl ether, 10% polyethanol 2000, 10% modified hydrogenated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com