Flat hydraulic torque converter with pitched blade for saloon car

A technology of torque converter and blade, applied in fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as multi-space, save space and solve the effect of limited layout

Inactive Publication Date: 2010-09-15

ZHEJIANG NORMAL UNIVERSITY +1

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

German ZF Company, LUK Company, and American Daimler-Chrysler Company have all developed flat hydraulic torque converters used in car automatic transmissions. 0.25 to 0.4 times, but the drive train of front-wheel drive and front-engine cars needs more space, and the hydraulic torque converter should be flatter

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

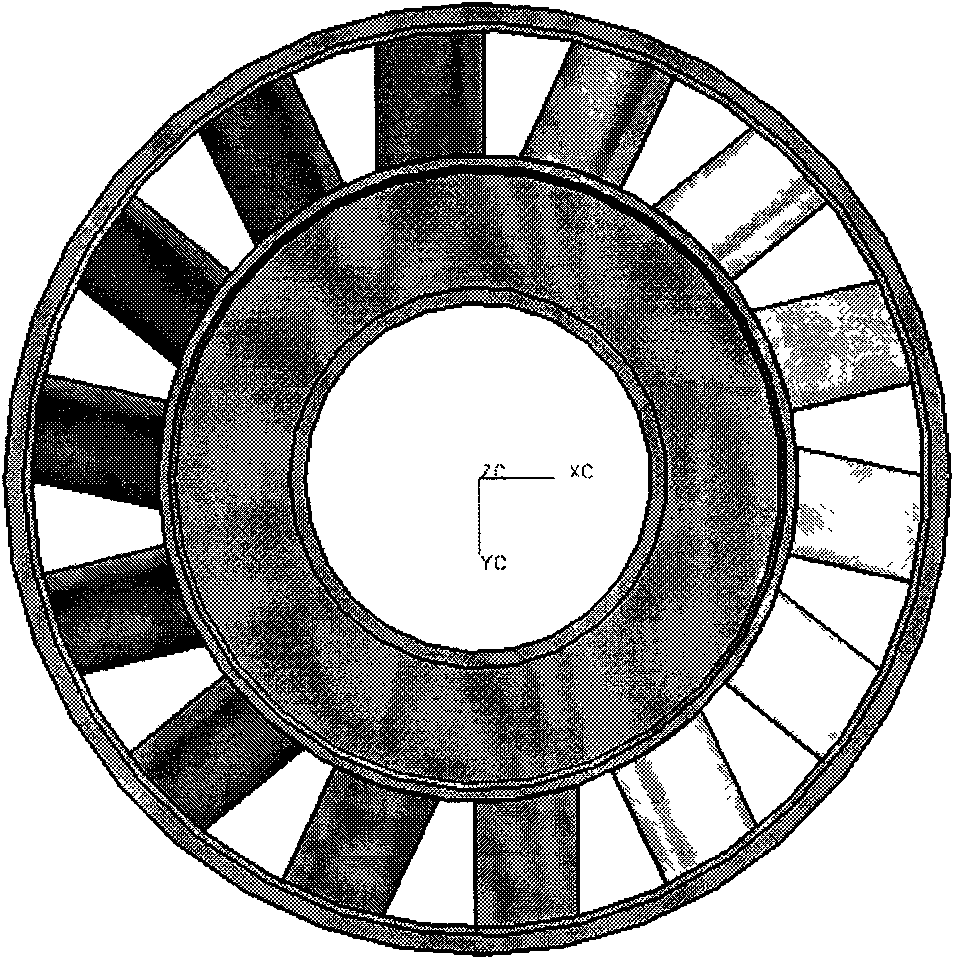

Login to View More Abstract

The invention relates to a flat hydraulic torque converter with a pitched blade for a saloon car. In the flat hydraulic torque converter with the pitched blade for the saloon car, a hydraulic torque converter cover wheel and a pump pulley are welded into a whole and are connected with an engine through connecting claws to drive the pump pulley to rotate; turbines are connected with an output shaft; a guide wheel is fixed at a guide wheel seat through a one-way clutch; fluid transmission oil circularly flows in the three impellers; and a lock-up clutch pressure plate is provided with an anti-vibrating spring, an end face thrust bearing is arranged between the pump pulley and the guide wheel, and end face thrust bearings are arranged among turbines. The loop circle of the hydraulic torque converter is flatter, the width of the loop circle is only 0.21 times of the effective diameter of the hydraulic torque converter. The flat hydraulic torque converter with the pitched blade saves precursor transmission system space of the saloon car, and effectively solves the problem that the arrangement space of the transmission system is limited. The C0 before leaning and the C0 after leaning are shown in the specification, and the nominal torque TBg0 before leaning and the nominal torque TBg0 after leaning respectively are 3.65N.m and 40N.m. The capacity coefficient of the torque converter is decreased, the nominal torque is increased, and the invention can adopt smaller effective diameter to meet the matching requirement of an engine with the same power of the saloon car.

Description

technical field The invention relates to a hydraulic transmission device for a vehicle, in particular to a flat hydraulic torque converter with inclined blades for a car. Background technique With the continuous development of my country's car industry, the output of all kinds of medium and high-end cars with automatic transmission has increased sharply. At present, the most widely used and most mature car automatic transmission is the automatic transmission with hydraulic torque converter. With the continuous improvement of car power, fuel economy, and ride comfort, the performance requirements for the automatic transmission of the car transmission system are also getting higher and higher, and the hydraulic torque converter, which is the core component of the automatic transmission, must also be developed accordingly. Change. Especially in recent years, for front-engine front-wheel-drive cars, due to the limitation of drive train space, the hydraulic torque converter ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16H41/04F16H41/26

Inventor 朱喜林刘春宝马文星邓洪超仵晓强黄伟王丽娟

Owner ZHEJIANG NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com