Pipeline electric heating rapid water boiler

A water boiler and pipe heater technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of inability to provide boiling water in time and quickly, residual water in the machine, and slow heating speed, etc. The effect of waiting time, preventing dry burning, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

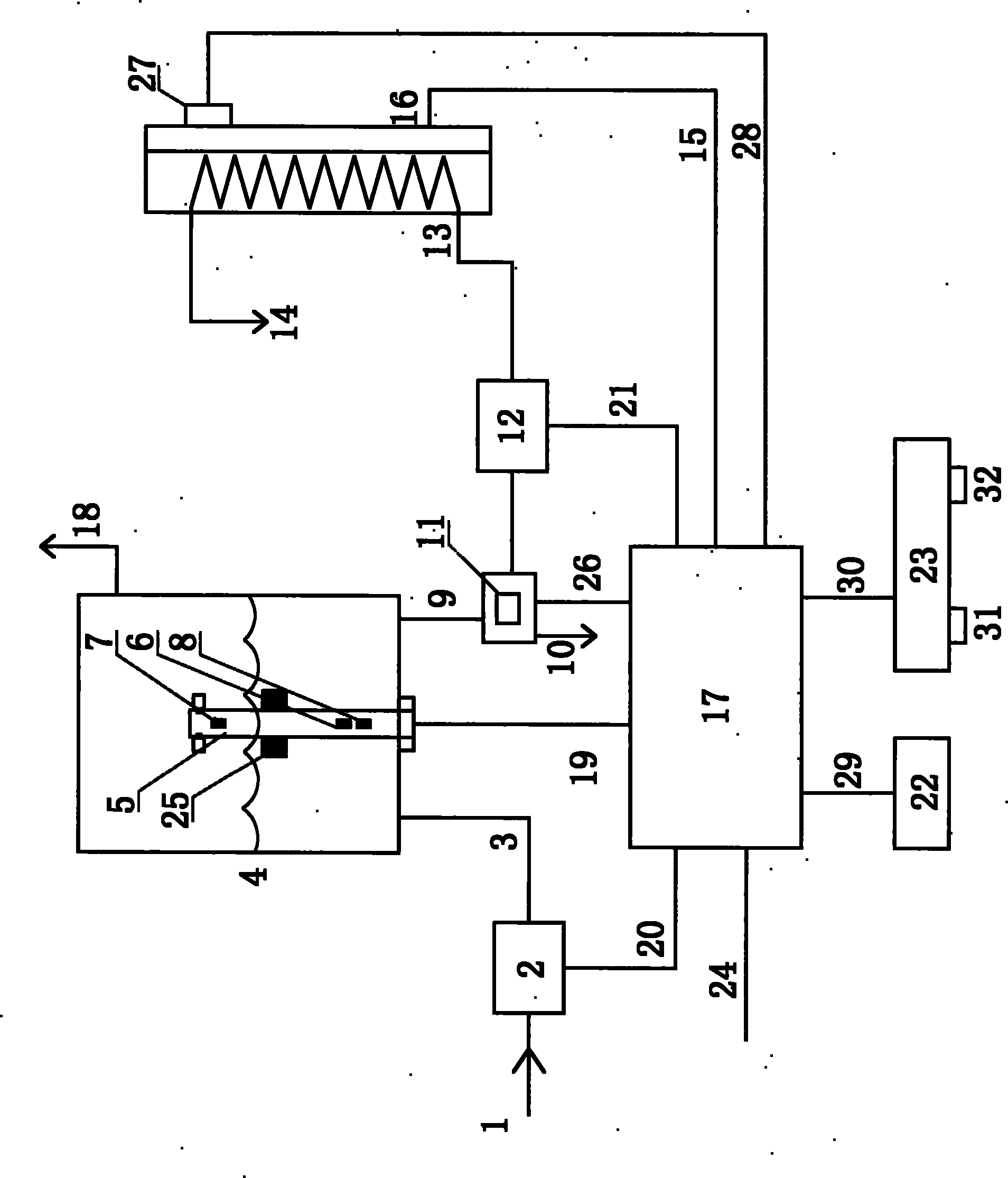

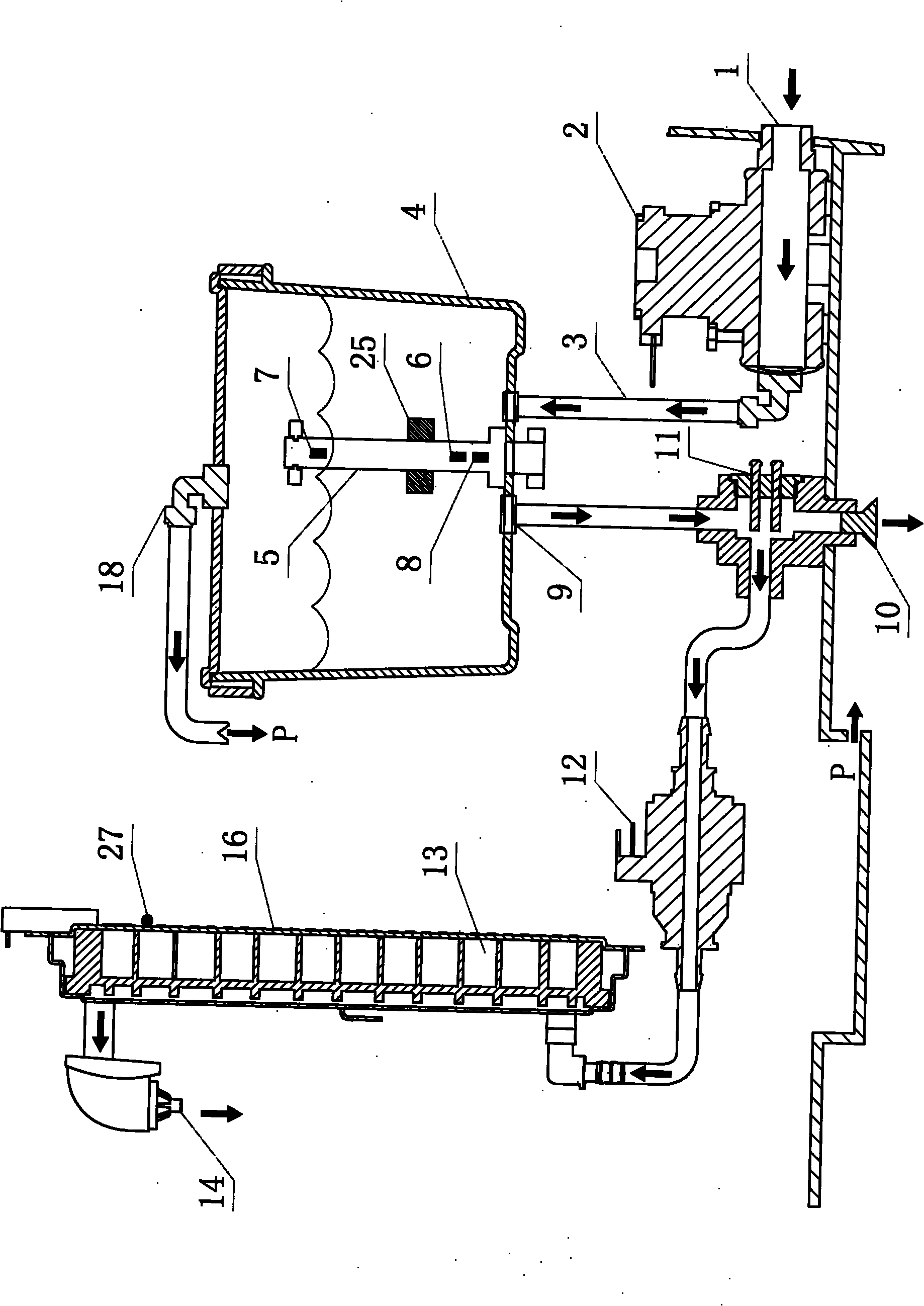

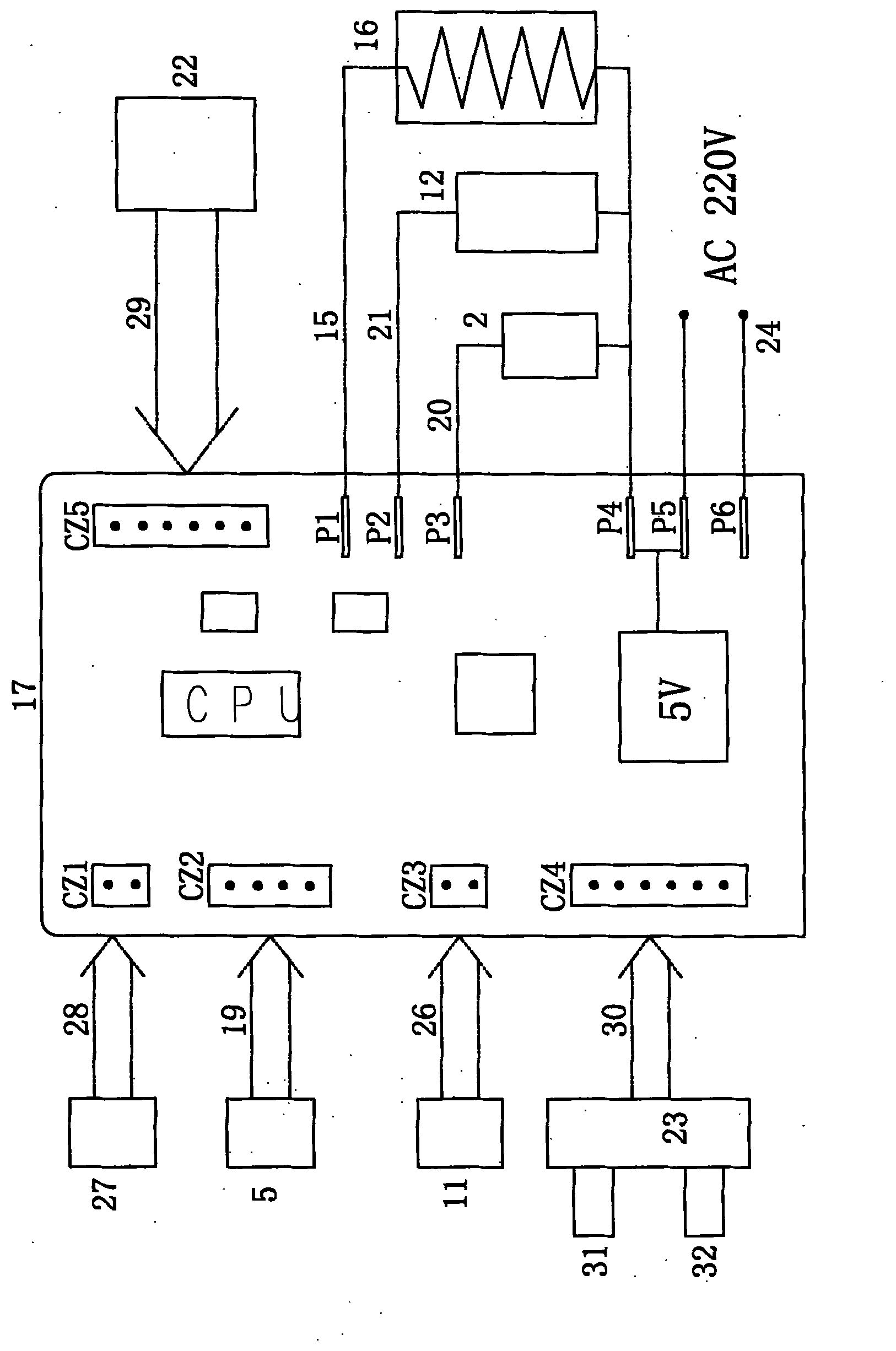

[0013] The electric heating box of the present invention is as figure 1 with figure 2 Shown, comprise water inlet solenoid valve 2, water level control box 4, water quality sensor 11, water inlet pump 12 and pipe heater waterway 13, electrothermal film 16, main control panel 17, water quality indicator 22, control panel 23. The water flow path is connected by the water inlet 1 and the solenoid valve 2, through the water tank inlet pipe 3, connected to the water level control box 4, and the water outlet 9 of the water level control box is connected to the water quality sensor 11, and then connected to the heater water channel 13 through the water pump 12, and the water flows out from the boiling water outlet 14 . Electromagnetic valve 2 controls water inlet pipe 3 and water flows into water level control box 4, and water level sensor 5 is set in water level control box 4, and a magnetic buoy 25 is set in water level sensor cover, and high water level switch 7 (normally discon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com