Pipeline electric heating rapid water boiler

A technology for boiling water machines and pipe heaters, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of inability to provide boiling water in a timely and fast manner, slow heating speed, and large residual water in the machine, and achieve saving Waiting time, increase speed, and prevent dry burning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

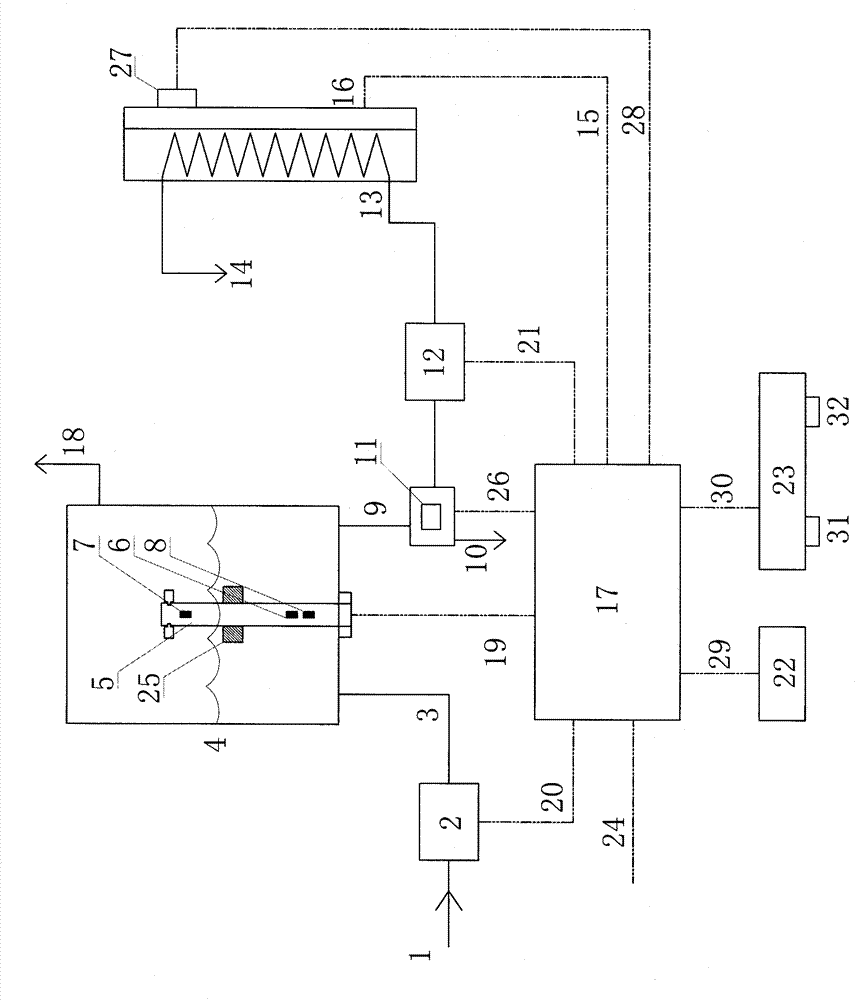

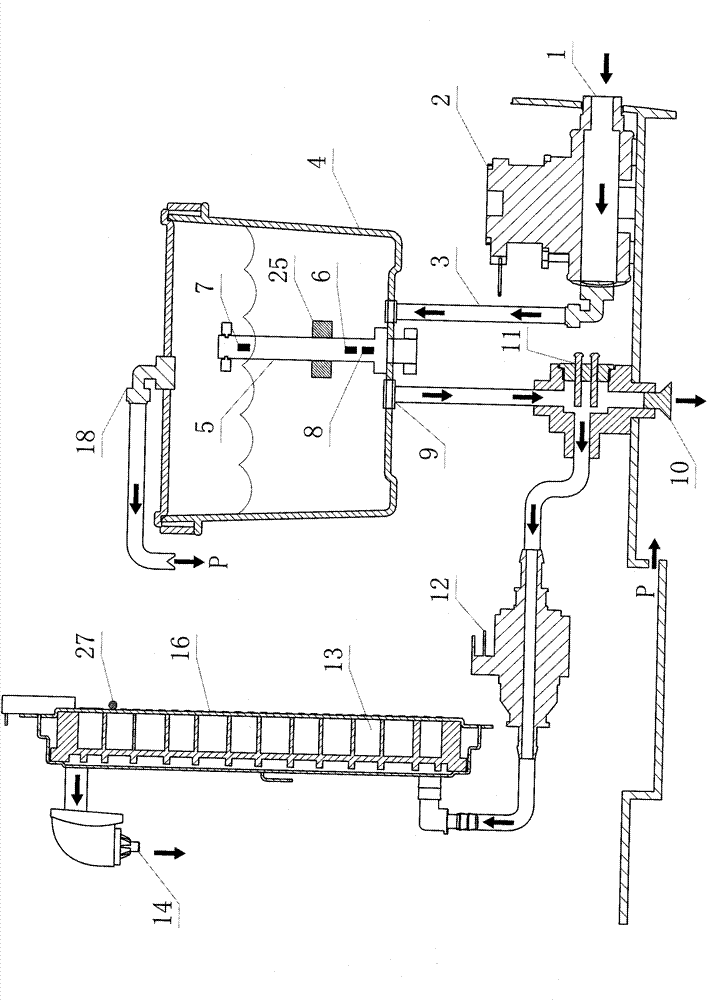

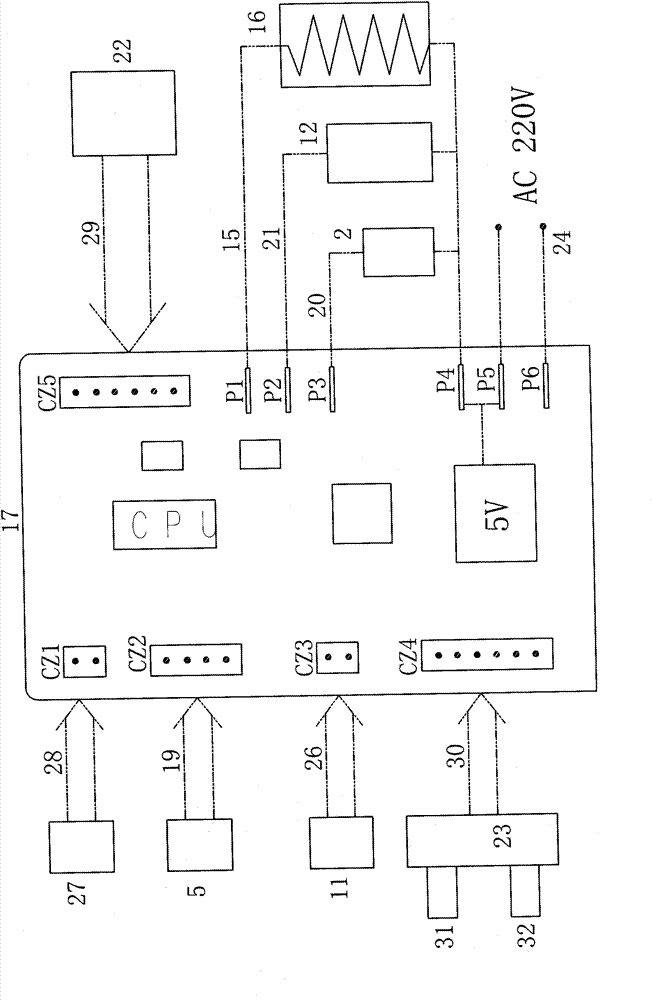

[0013] The electric heating box of the present invention is such as figure 1 with figure 2 As shown, it includes a water inlet solenoid valve 2, a water level control box 4, a conductivity sensor 11 for detecting water quality, a water inlet pump 12 and a pipe heater channel 13, an electric heating film 16, a main control board 17, a water quality display 22, and a control panel 23. The water flow path is connected to the water inlet 1 and the solenoid valve 2 through the water tank inlet pipe 3 to the water level control box 4, the water outlet 9 of the water level control box is connected to the conductivity sensor 11 that detects the water quality, and then the water pump 12 is connected to the heater water channel 13 The boiling water outlet 14 flows out. The solenoid valve 2 controls the water inlet pipe 3 and the water flows into the water level control box 4. The water level control box 4 is equipped with a water level sensor 5, the water level sensor is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com