Gas boiler

A gas boiler and gas technology, applied in the field of gas boilers, can solve problems such as explosion and fire easily, and achieve the effect of avoiding inconvenience and danger and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

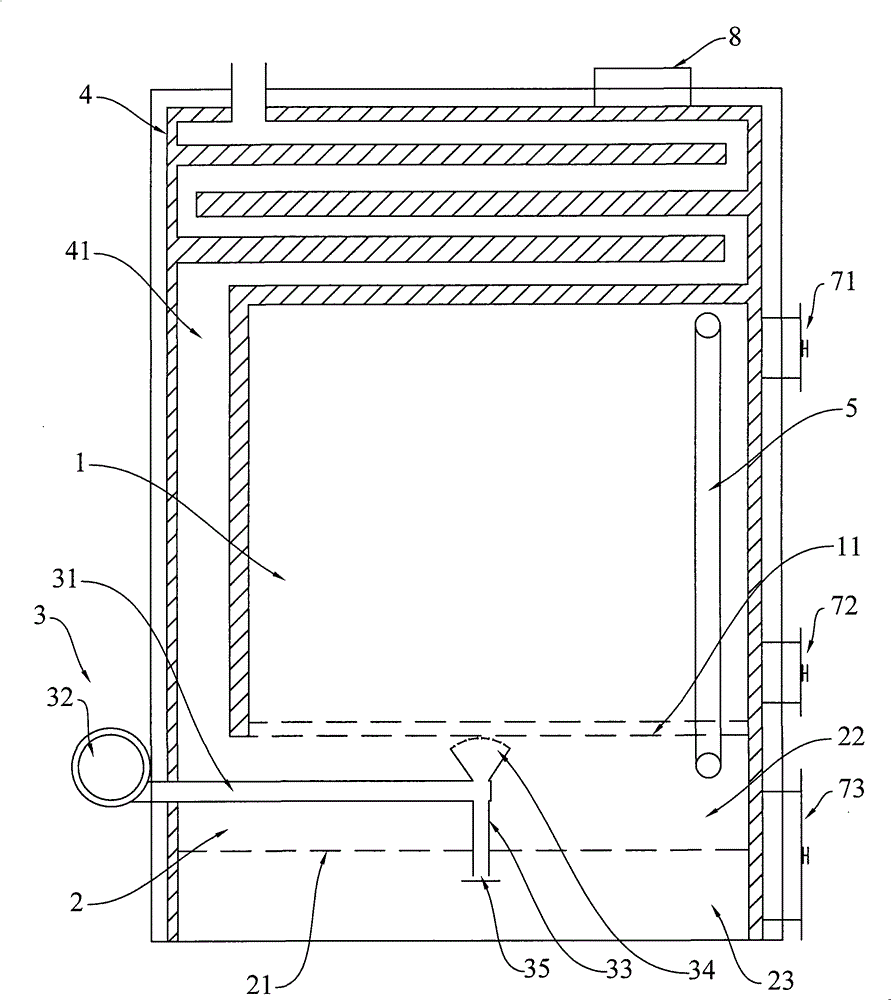

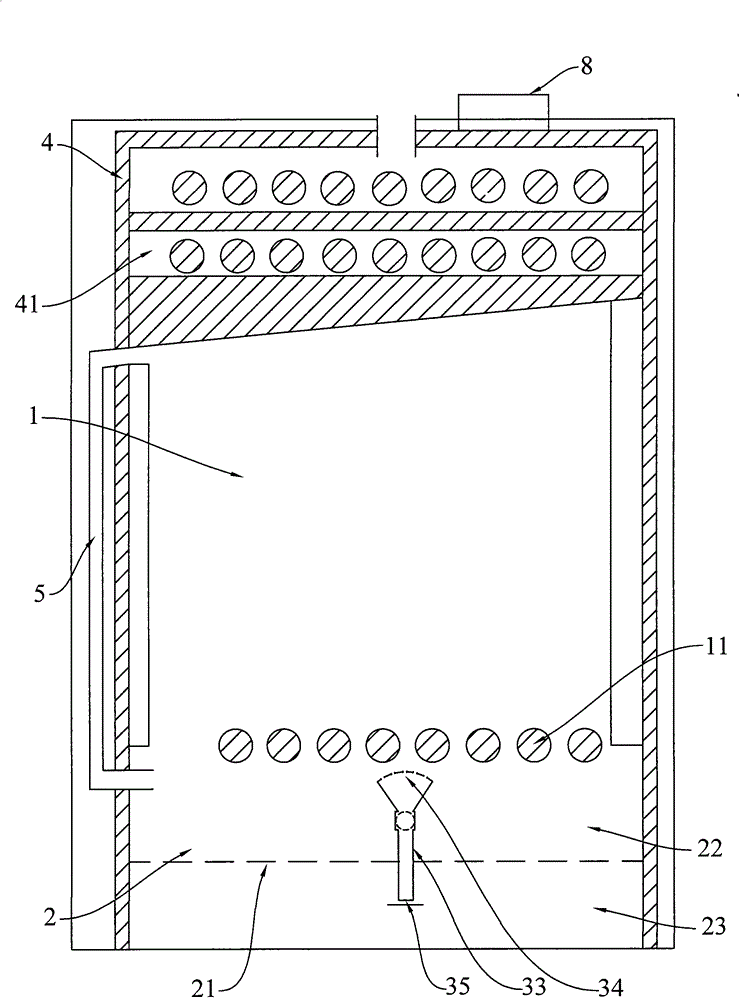

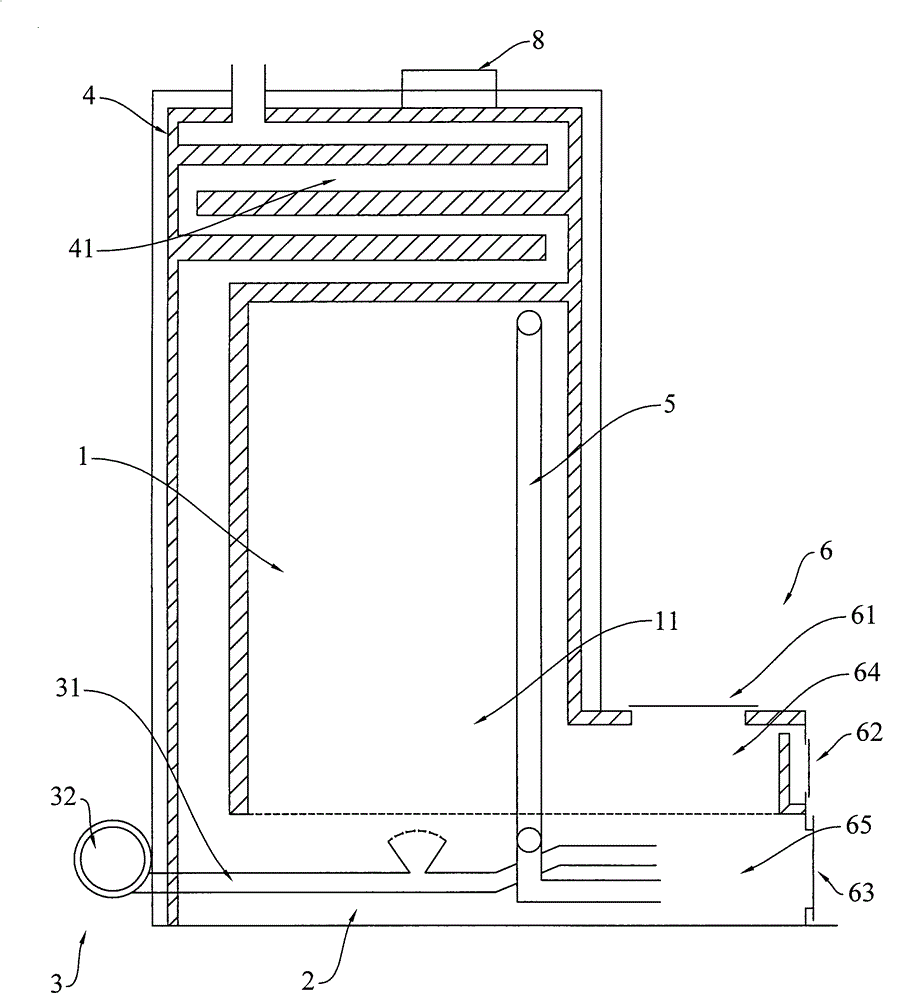

[0046] figure 1 with figure 2A specific embodiment of the present invention is shown, a gas boiler, comprising: a coal gas generating chamber 1 with incomplete combustion of coal, and a substantially closed side wall and top; a gas combustion chamber 2 communicating with the gas generating chamber 1 ; an air supply device 3 for providing combustion-supporting air to the gas generating chamber 1 and the gas combustion chamber 2; and a heat exchange device 4 for deriving the hot gas in the gas combustion chamber 2 for heat exchange. On the side wall of the gas generating chamber 1, a first furnace door 71 and a second furnace door 72 are respectively provided near the upper and lower ends, wherein the upper first furnace door 71 is mainly used to generate heat from the gas. Coal lumps are added in the chamber 1; and the second furnace door 72 below can be used to ignite coal lumps in its position in addition to being used for adding coal. The gas combustion chamber 2 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com