Liquid weighing device and automatic control method thereof

A weighing device and liquid technology, applied in liquid level control, non-electric variable control, measuring devices, etc., can solve the problems of material waste and product quality, and achieve the effects of avoiding waste, improving competitiveness, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

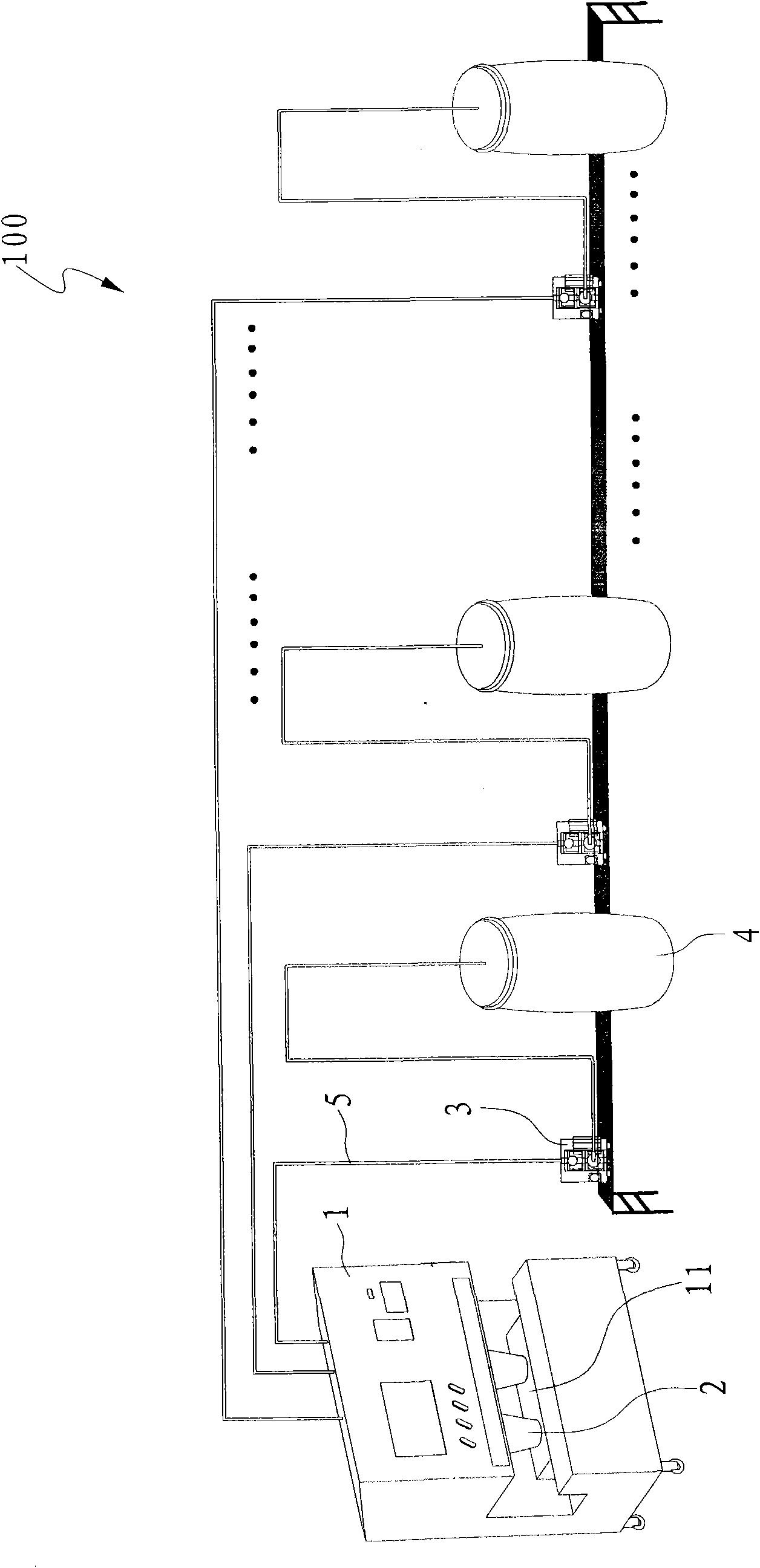

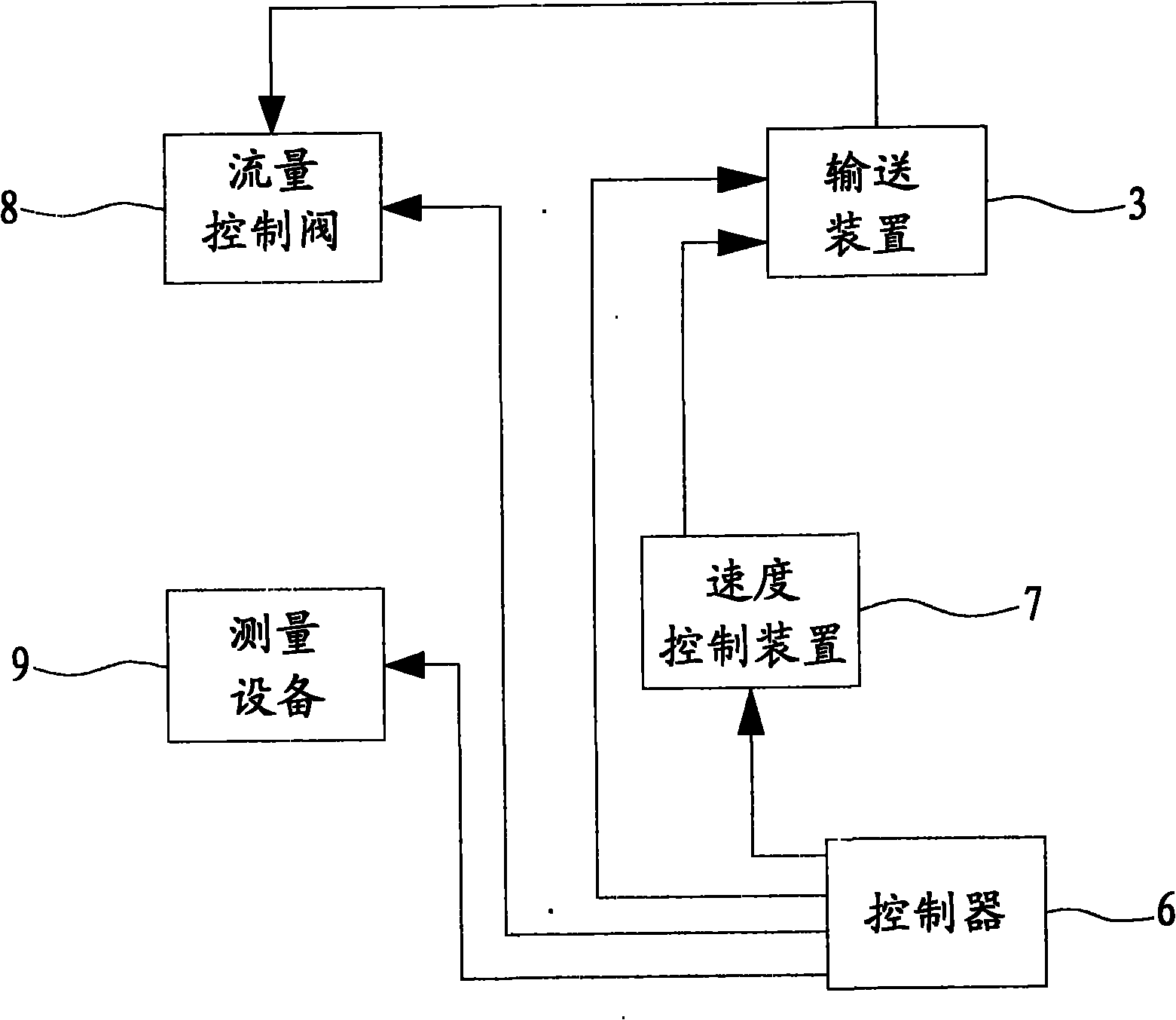

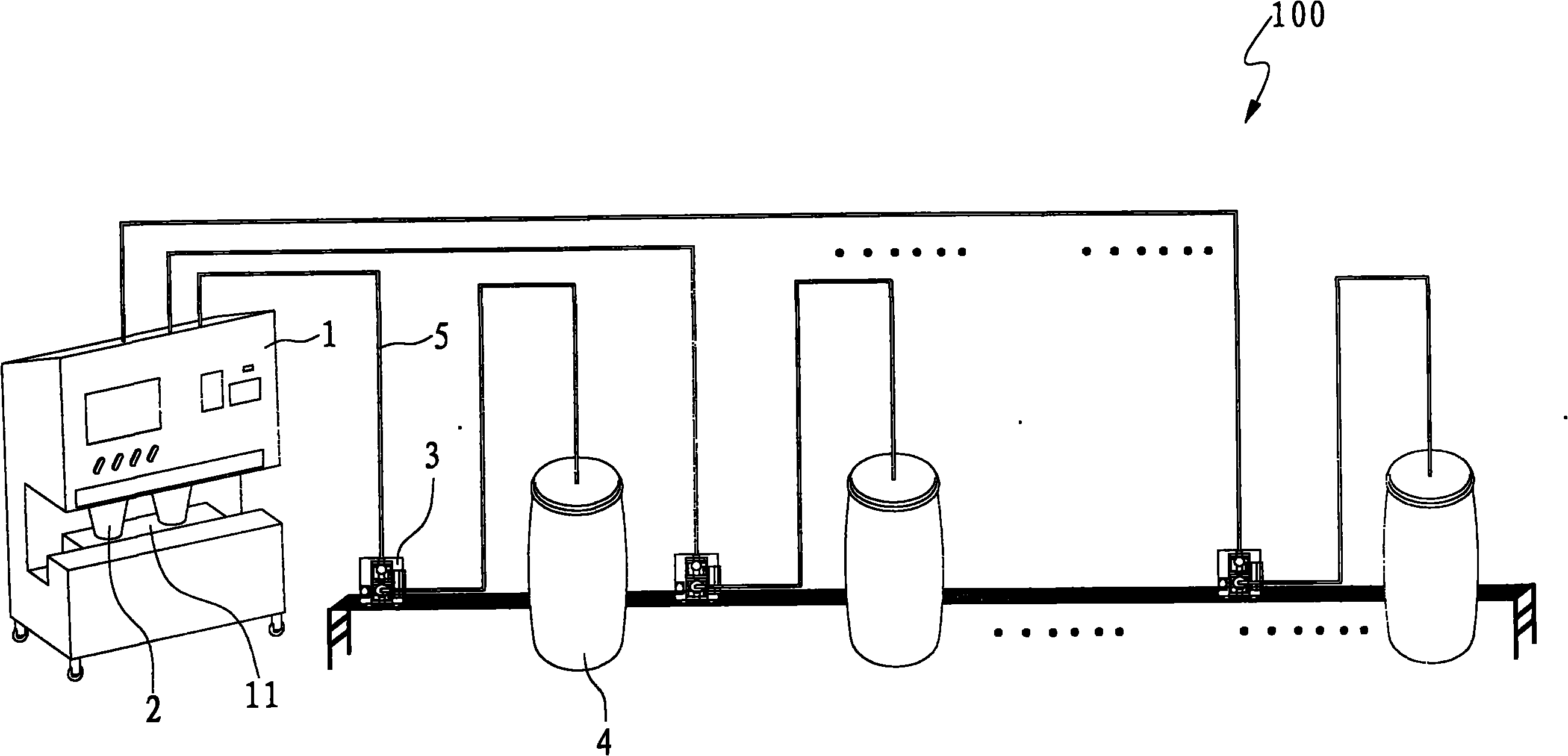

[0033] Such as figure 1 and figure 2 As shown, it shows a liquid weighing device 100 related to the present invention, including a machine platform 1, a storage tank 2, at least one delivery device 3 and a flow control valve 8 matching the number of delivery devices 3, in:

[0034] The machine platform 1 is provided with a measuring device 9 and a controller 6. In this embodiment, the measuring device 9 adopts an electronic scale 11. Of course, other weighing or weighing devices commonly used in the art, such as a flow meter, etc., can also be used; The electronic scale 11 is used to place the filling bucket 2 and to weigh the filling bucket 2. The filling bucket 2 is connected to one end of each conveying device 3 through a pipeline 5 through each flow control valve 8, The other end of each conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com