Uniaxial compression creep experiment device and method for soft rock-soil material

A uniaxial compression, geotechnical material technology, applied in measurement devices, analytical materials, electromagnetic measurement devices, etc., can solve the problem of soft and weak geotechnical materials unable to carry out creep experiments, etc., and achieves compact structure, high degree of automation, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

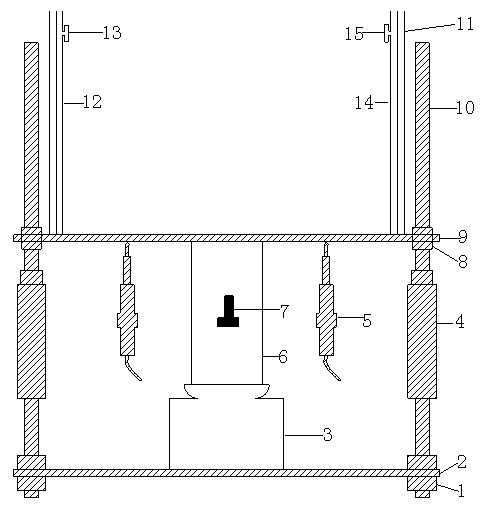

[0047] Such as figure 1 , 2 As shown, a uniaxial compression creep test device for weak rock and soil materials includes a support device, a loading and unloading device and a measuring device. 6, the material test piece 6 and the lower part of the loading and unloading device are provided with measuring devices.

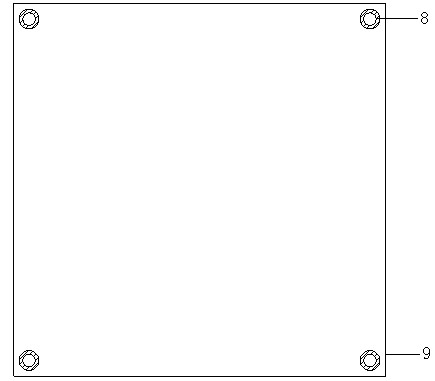

[0048] The support device includes a pressure plate 2, and a pressure plate positioning hole is respectively provided on the four corners of the pressure plate 2, and a support rod 10 is passed through each pressure plate positioning hole, and the support rod 10 passes through the leveling bolt 1 Fixed in the positioning hole of the pressure bearing plate, the upper part of the support rod 10 passes through the loading device, and the support rod 2 between the loading device and the pressure bearing plate 2 is covered with a movable flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com