Man-machine interactive food processing control device capable of preprogramming

A food processing and control device technology, applied in the field of pre-programmable human-computer interaction control devices, can solve the problems of inability to track and understand the processing process, inability to achieve precise process control, inability to automatically save processing parameters, etc., to achieve software defects and hardware errors Clear boundaries, improved software and hardware development efficiency, and convenient debugging and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

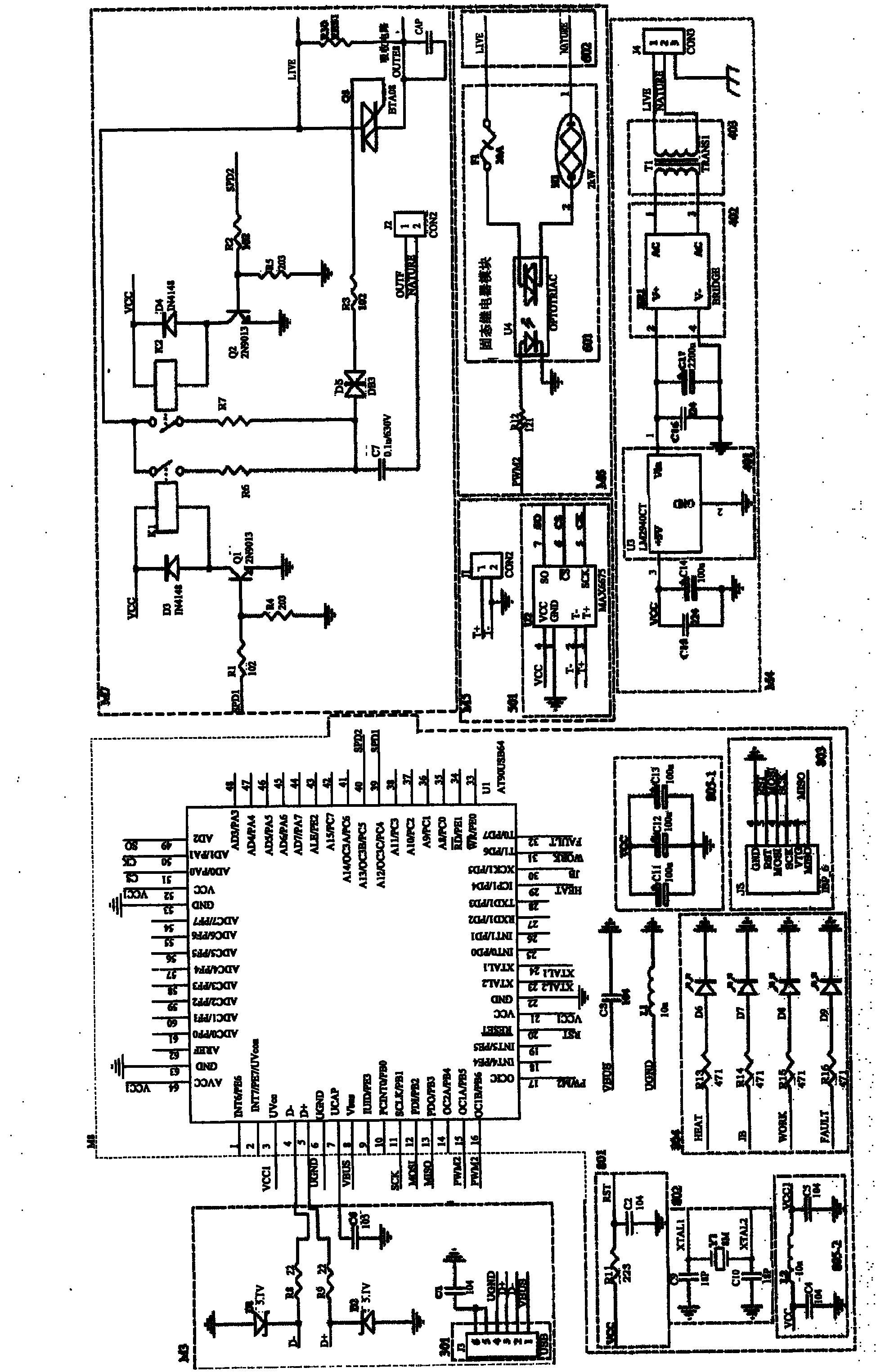

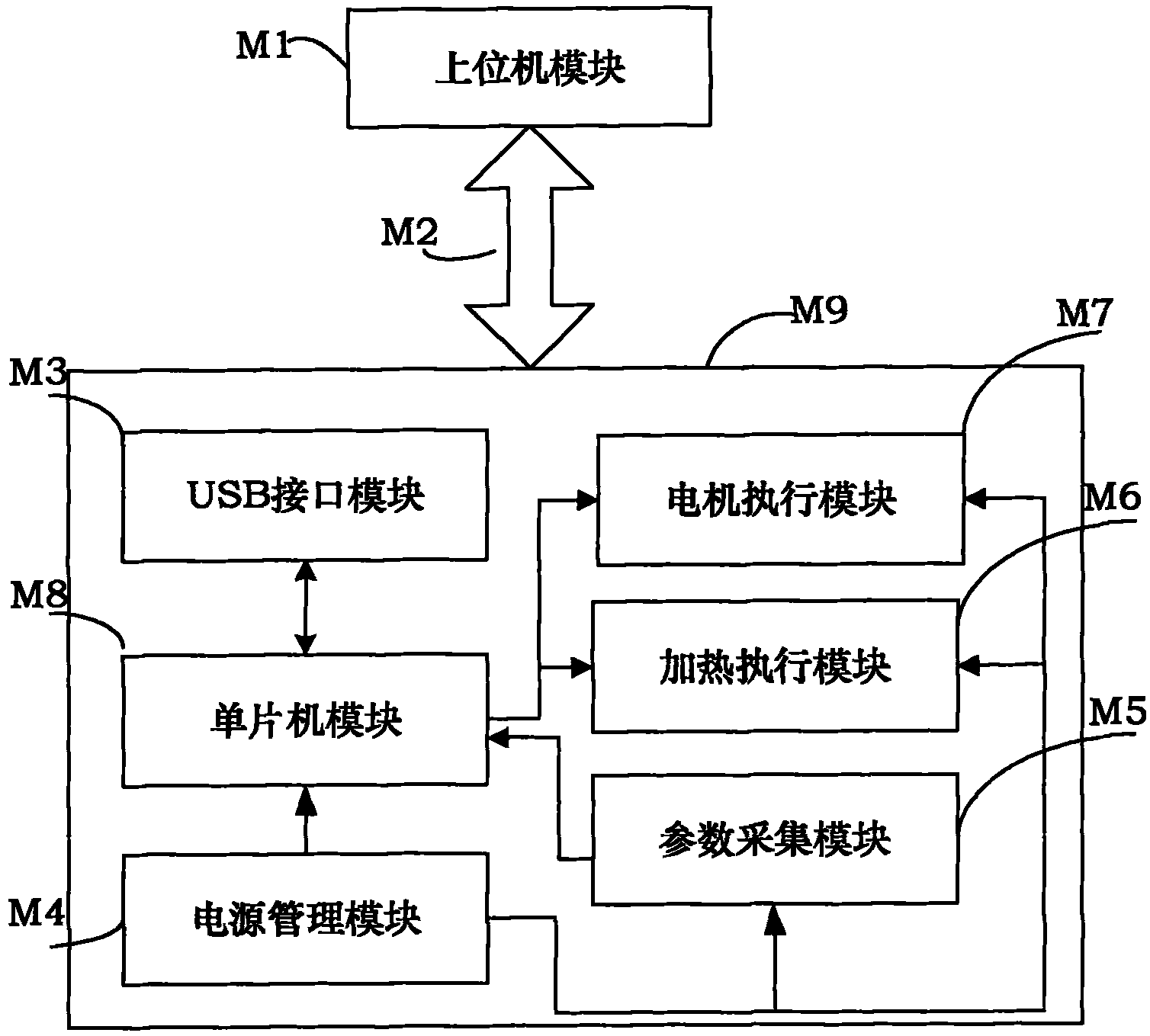

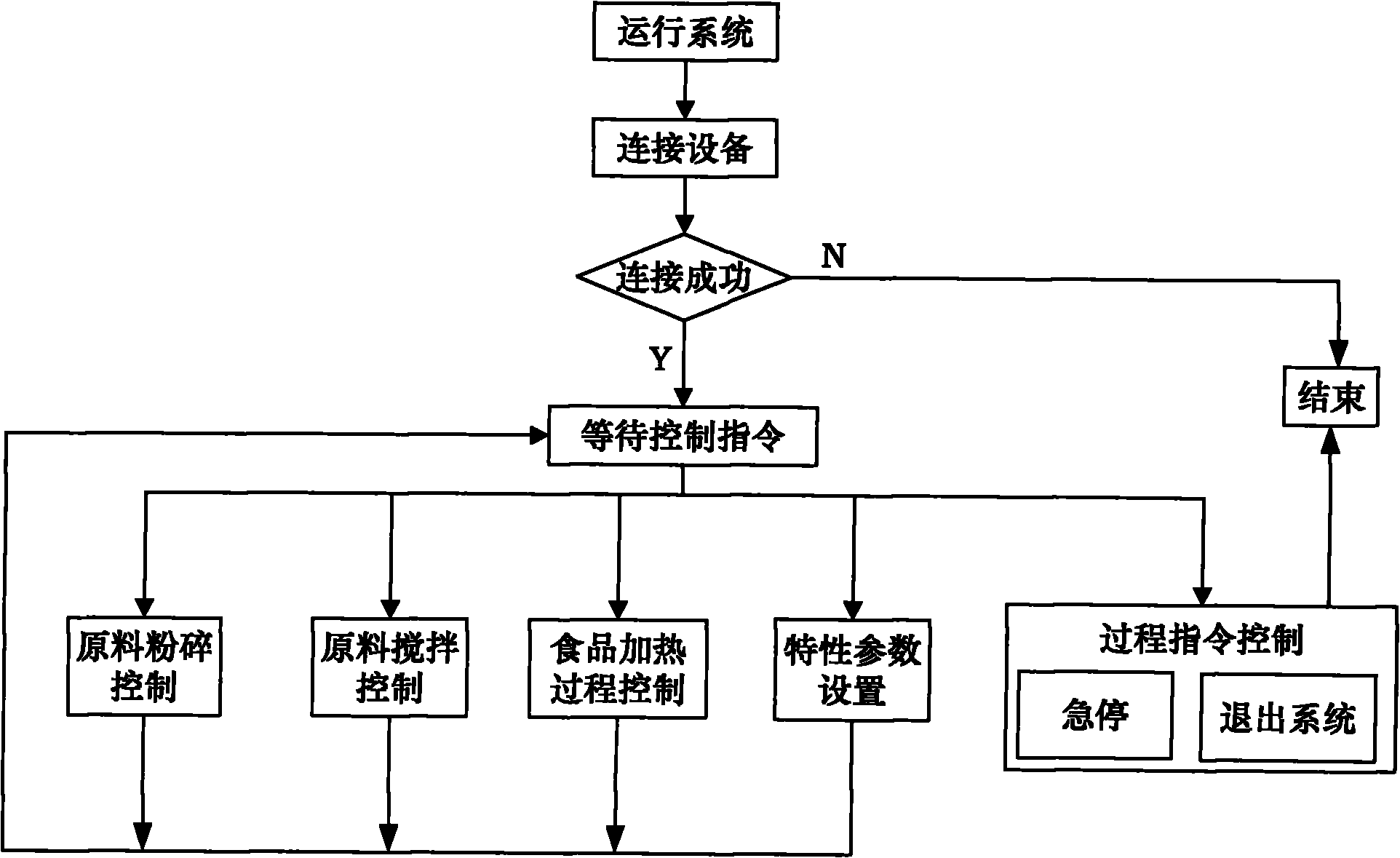

[0030] like figure 1 As shown, the present invention is a preprogrammable human-computer interaction food processing control device, which includes a host computer M1, a USB connection line M2 and a lower computer. The upper computer M1 is an ordinary PC with a USB communication interface; the lower computer includes the lower computer substrate M9 and the USB interface module M3 embedded on the lower computer substrate M9, the power management module M4, the parameter acquisition module M5, the heating execution module M6, the motor Execution module M7 and MCU module M8. The power management module M4 supplies the external 220V AC power of the device to the motor execution module M7 and heating execution module M6 in the lower computer; at the same time, it processes the external 220V AC power into 5V DC power and supplies it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com