Disc permanent-magnet synchronous multi-combination power DC motor group

A permanent magnet synchronous, combined power technology, applied in synchronous motors with static armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc., can solve the problem of shortened vehicle mileage and shortened battery life. , the speed-up time of the whole vehicle is prolonged, etc., to achieve the effect of fast start-up speed-up time, reduced power consumption, and shortened discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

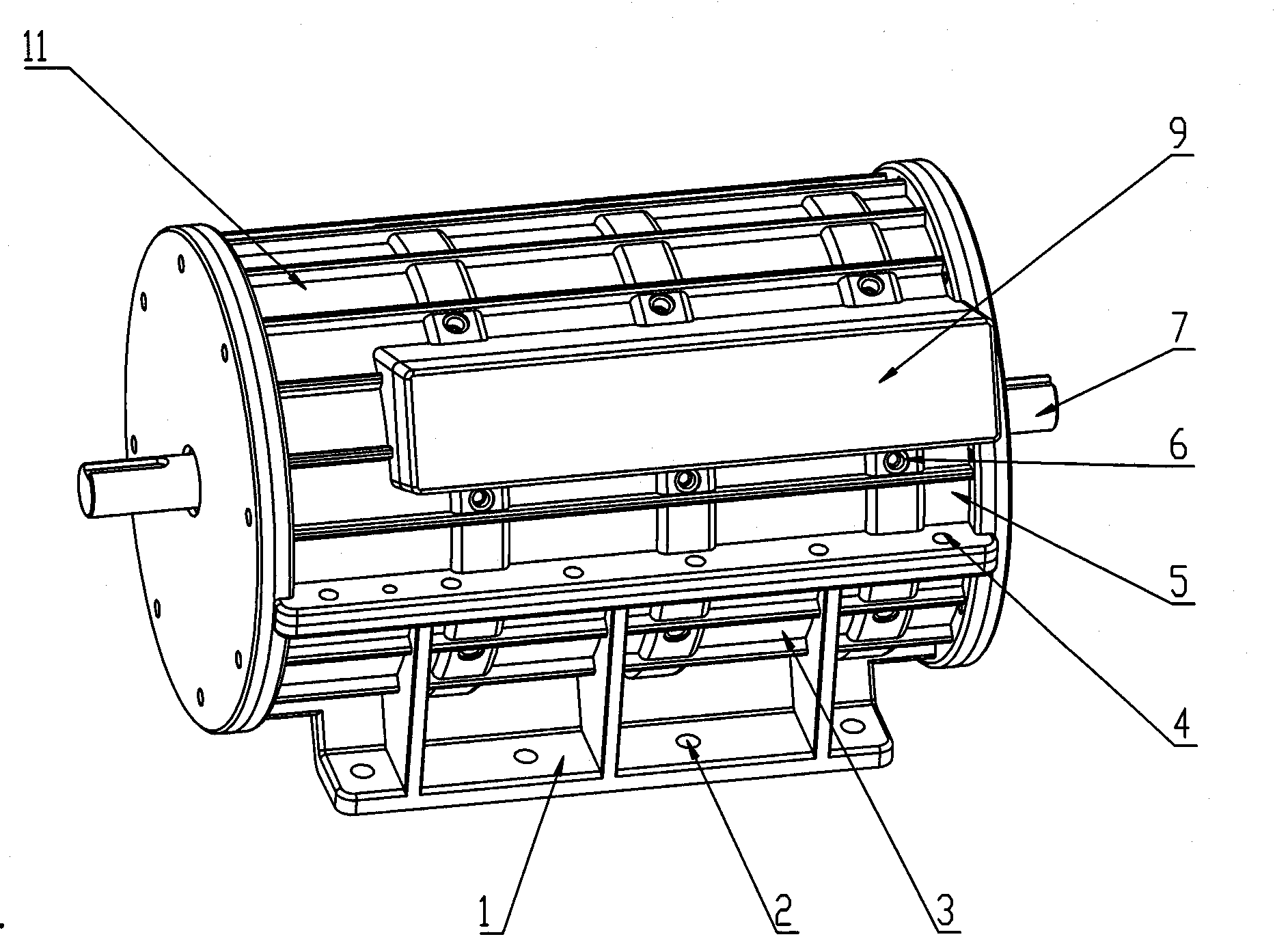

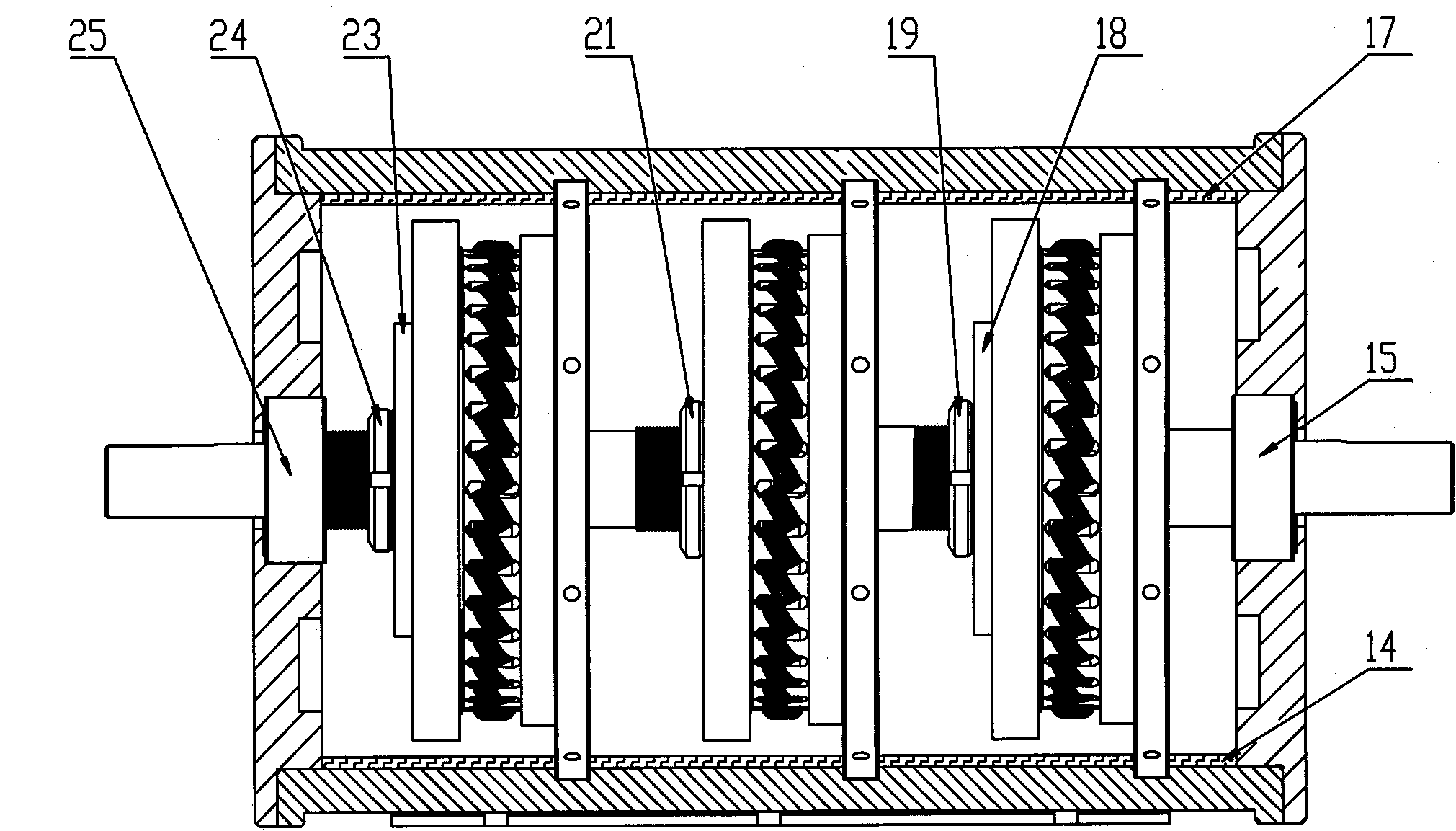

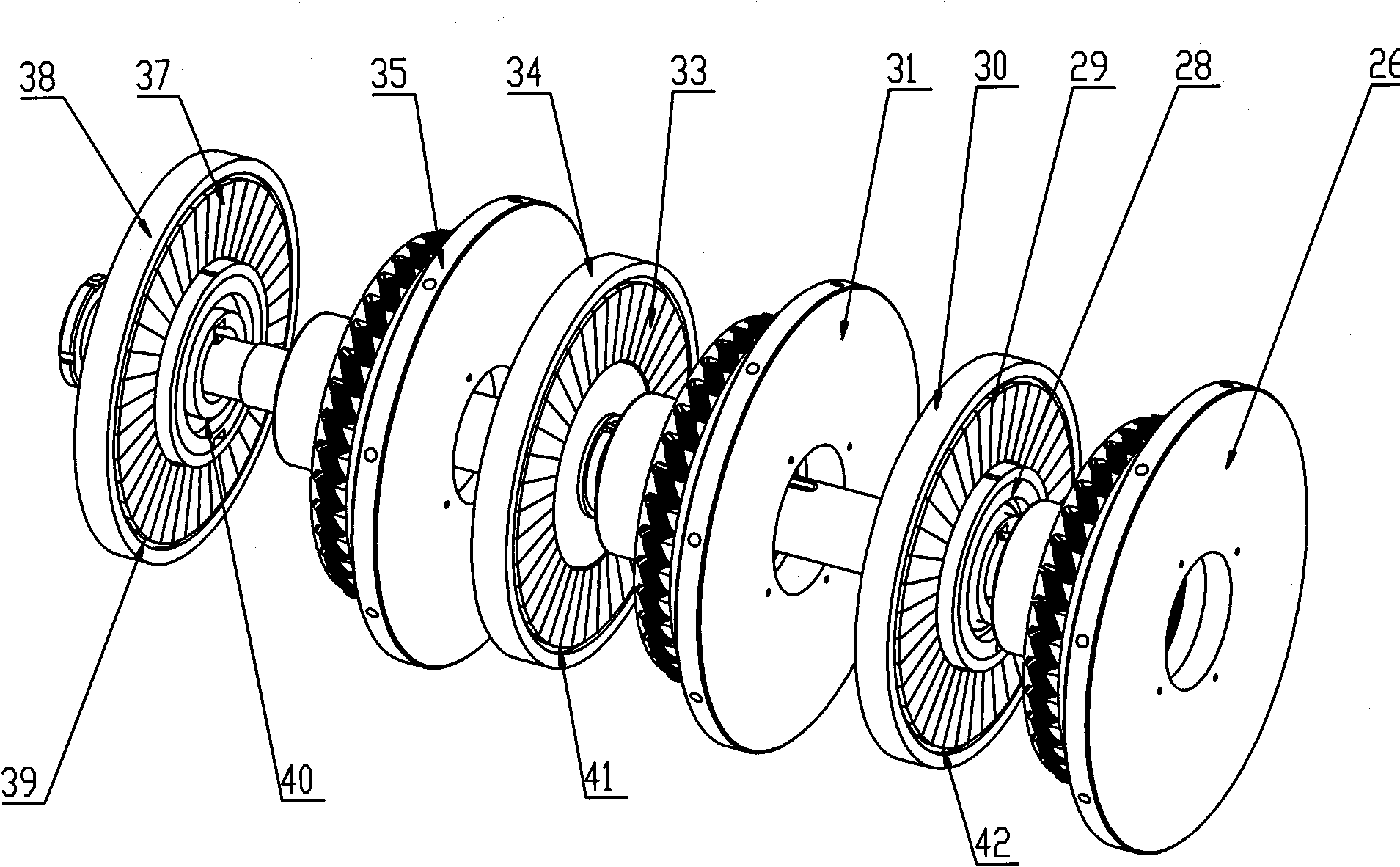

[0025] Such as figure 1 , 2 , 3, and 4, the disc permanent magnet synchronous multi-combination power DC motor unit 11 includes a casing, the casing is composed of a lower casing 3 and an upper casing 5, and the lower casing 3 and the upper casing 5 are provided with The fixing screw 4, the lower casing 3 is provided with a base 1, the casing 3, 5 is also provided with a synchronous multi-combination power motor stator fixing screw 6 and plays a fixing role, and an insulating material 14, 17 is also provided with an insulating effect, The junction box 9 is provided with a power cord, and the whole motor is fixed by the fixing screws 2 on the base 1 . The pole pairs of the three motors are 10-40 pairs, and uneven air gaps are used. Of course, the number of motors here can be increased or decreased according to needs, but there must be at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com