Prestressed anchor cable pile sliding wall along river road shoulder and construction method thereof

A technology of prestressed anchor cable and construction method, applied in sheet pile wall, excavation, artificial island, etc., to achieve good quality, reduce the probability of group anchor effect, and reduce the effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0029] 1. Prestressed anchor cable pile-slab wall along the shoulder of the river

[0030] 1. Overall

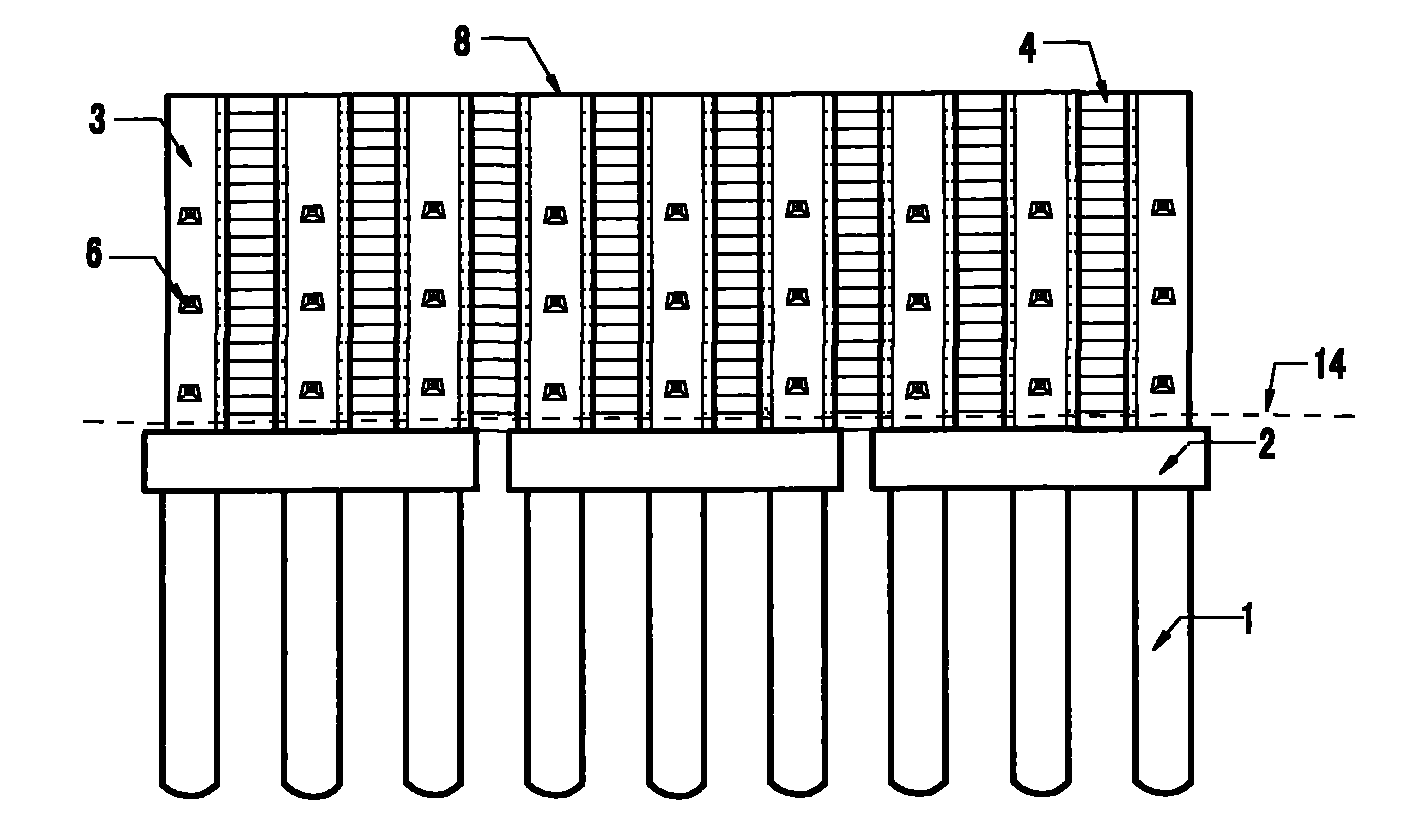

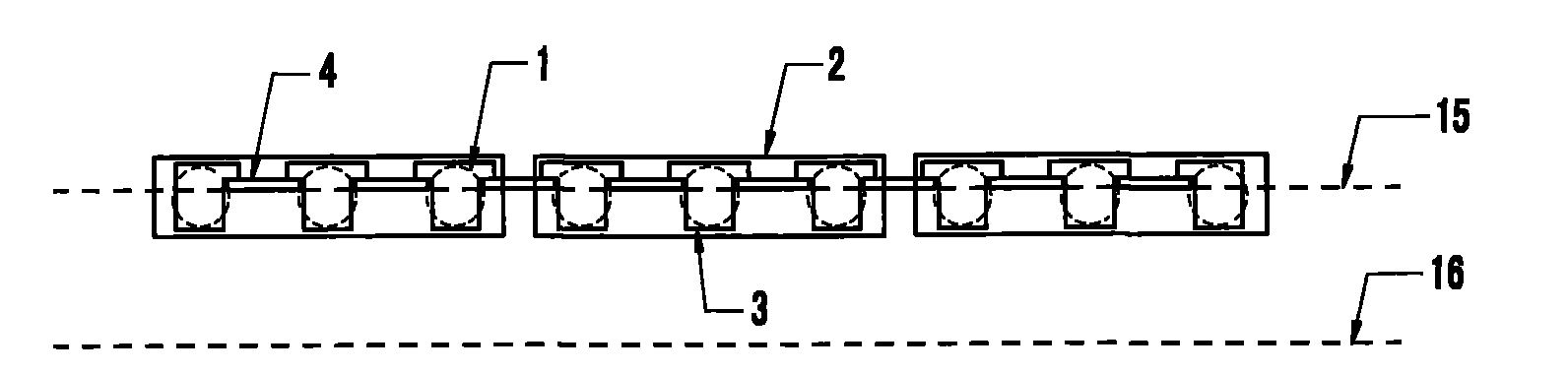

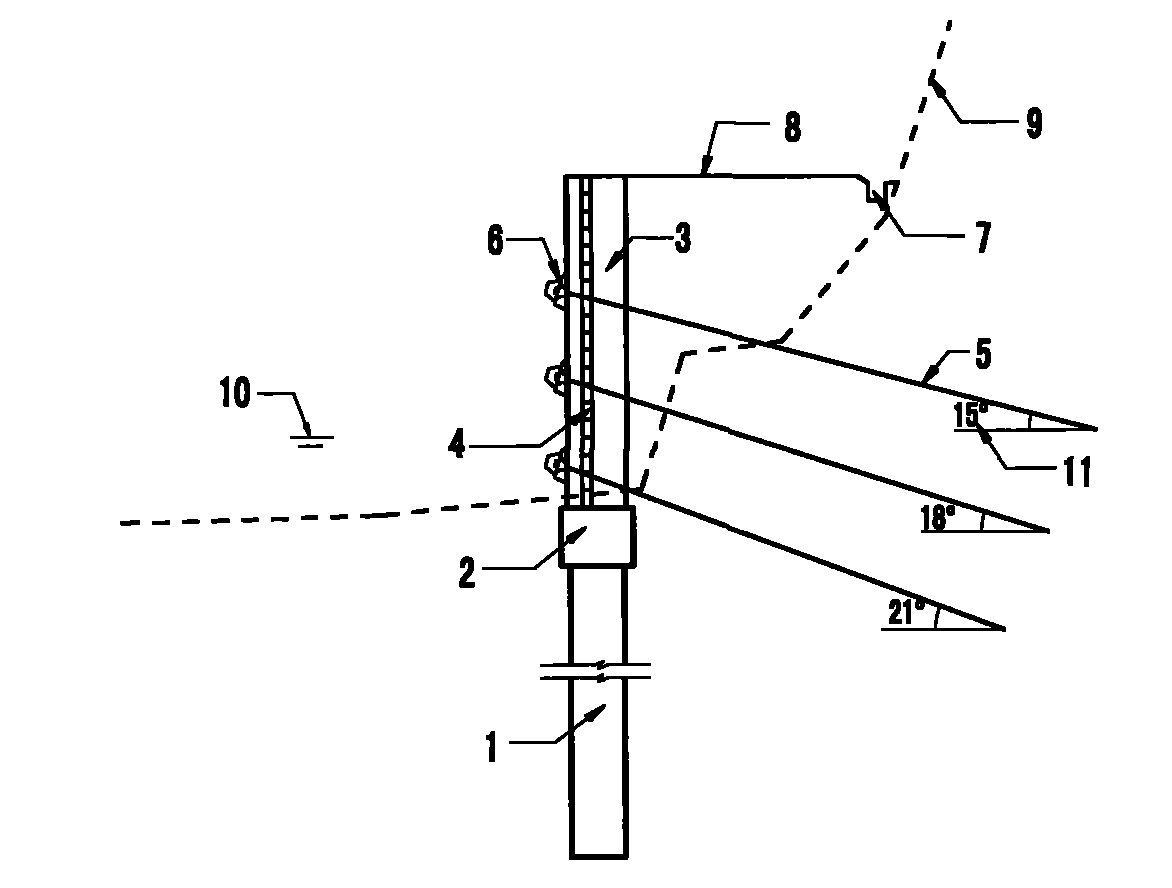

[0031] Such as figure 1 , 2 , 3, 4, the prestressed anchor cable pile-slab wall along the shoulder of the river includes round pile 1, connecting beam 2, T-shaped column 3, retaining plate 4, anchor cable 5 and anchor pier 6;

[0032] From bottom to top, round pile 1, connecting beam 2 and T-shaped column 3 are connected in sequence;

[0033] An earth retaining plate 4 is placed inside every two T-shaped columns 3;

[0034] On the T-shaped column 3, three anchor piers 6, upper, middle and lower, are respectively arranged from top to bottom;

[0035] The anchorage sections of the upper, middle and lower anchor cables 5 are anchored into the rock-soil layer, and after passing through the reserved holes 13 on the T-shaped columns, the three anchor cables 5 are respectively placed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com