Gas-liquid two-phase flow uniform distribution device

A technology of gas-liquid two-phase flow and uniform distribution, which is applied in the direction of gas/liquid distribution and storage, feeding devices, pipeline systems, etc. Low momentum and other issues, to achieve good environmental adaptability, maintenance-free, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

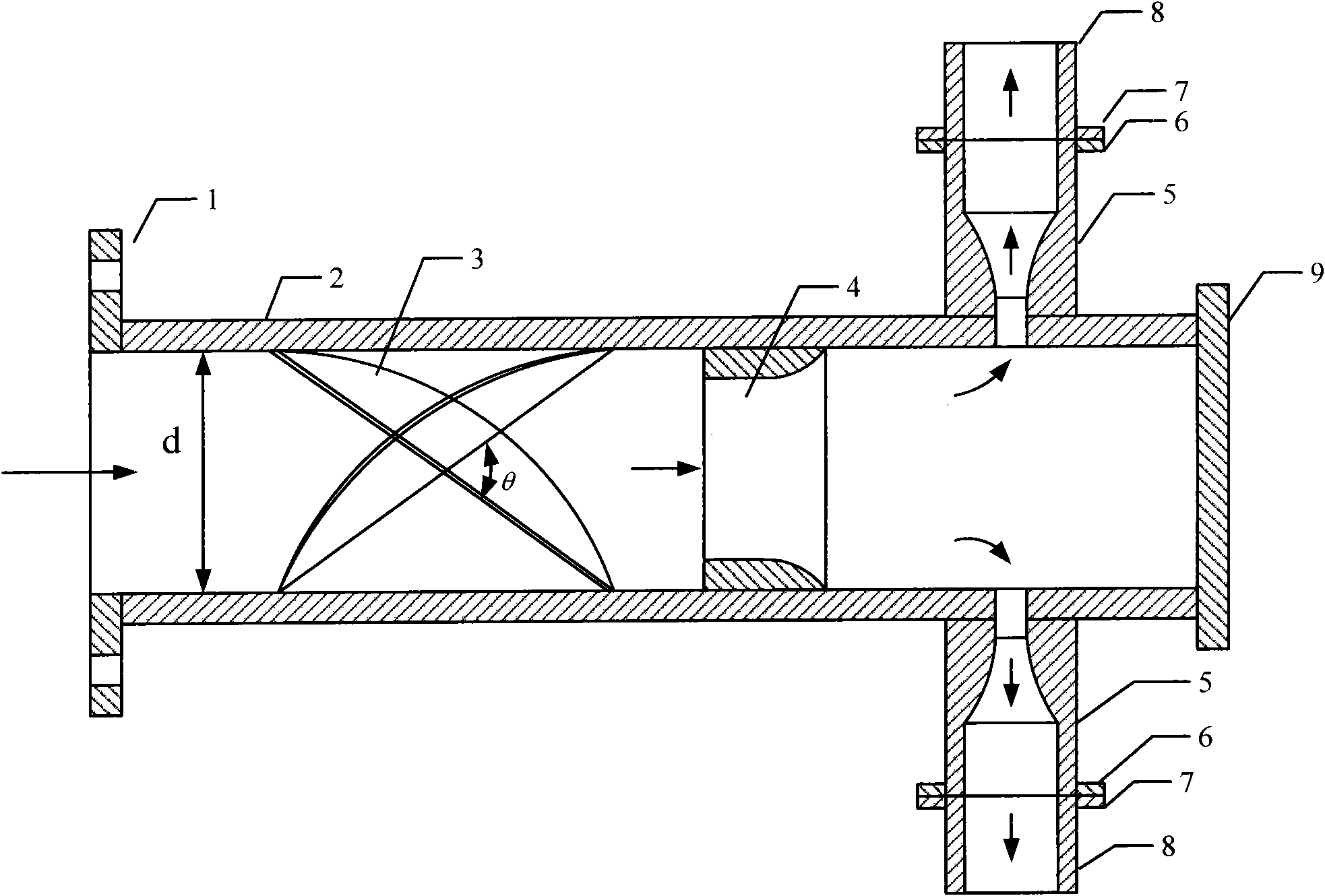

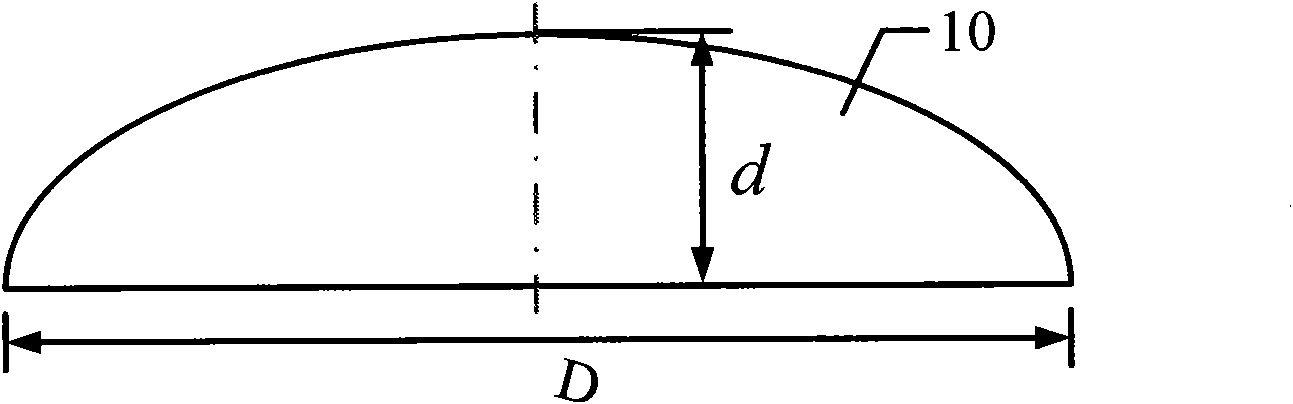

[0025] The structure of the gas-liquid two-phase flow uniform distribution device is as follows: figure 1 shown. It is composed of distribution main pipe 2, cyclone 3, rectifier 4, critical nozzle 5, distribution branch pipe 8, three connecting flanges 1, 6, 7, and a sealing blind plate 9 and other components.

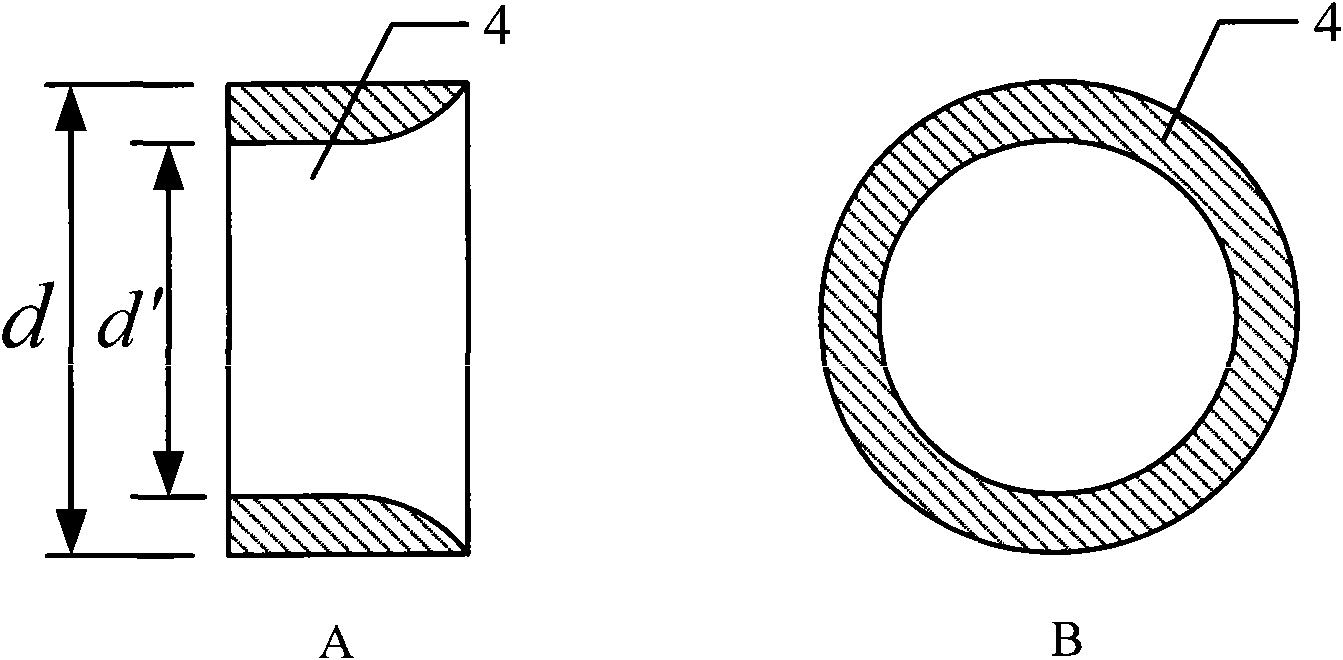

[0026] The specific connection is described as follows: the inlet of the distribution main pipe is connected to the two-phase flow pipeline through the distributor flange 1, the swirler 3 is arranged inside the distribution main pipe 2, the rectifier 4 is located downstream of the swirler 3, and the critical nozzle 5 is installed on the rectifier On the pipe wall downstream of 4, the outlet of the critical nozzle is connected with the upstream flange 7 of the distribution branch pipe through the downstream flange 6 of the critical nozzle, and the end of the distribution main pipe 2 is blocked by a sealing blind plate 9.

[0027] The function of the swirler 3 and the r...

Embodiment 2

[0036] Figure 6 Shown is the critical nozzle structure and installation diagram of the second embodiment of the gas-liquid two-phase distributor. In the second embodiment, the number of critical nozzle throat nozzles 11 of the distributor is two, and the two critical nozzles are arranged asymmetrically on the pipe wall. The inner diameter of the throat of the critical nozzle 11 is 1 / 20 of the diameter d of the distribution main pipe 2 . The number of distribution branch pipes 8 is also two, and they are connected downstream of the critical nozzle 11 through flanges 6 and 7 . The other structures of the gas-liquid two-phase uniform distributor in Embodiment 2 are exactly the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com