Manufacturing method of heat collection element of selective absorption film with slightly uneven surface

A selective, absorbing film technology, used in solar collectors, solar collectors using working fluids, heating devices, etc., can solve the problems that performance cannot be greatly developed or breakthrough, difficult to obtain, etc., and achieve low emission. efficiency, prolong life, and efficiently collect heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

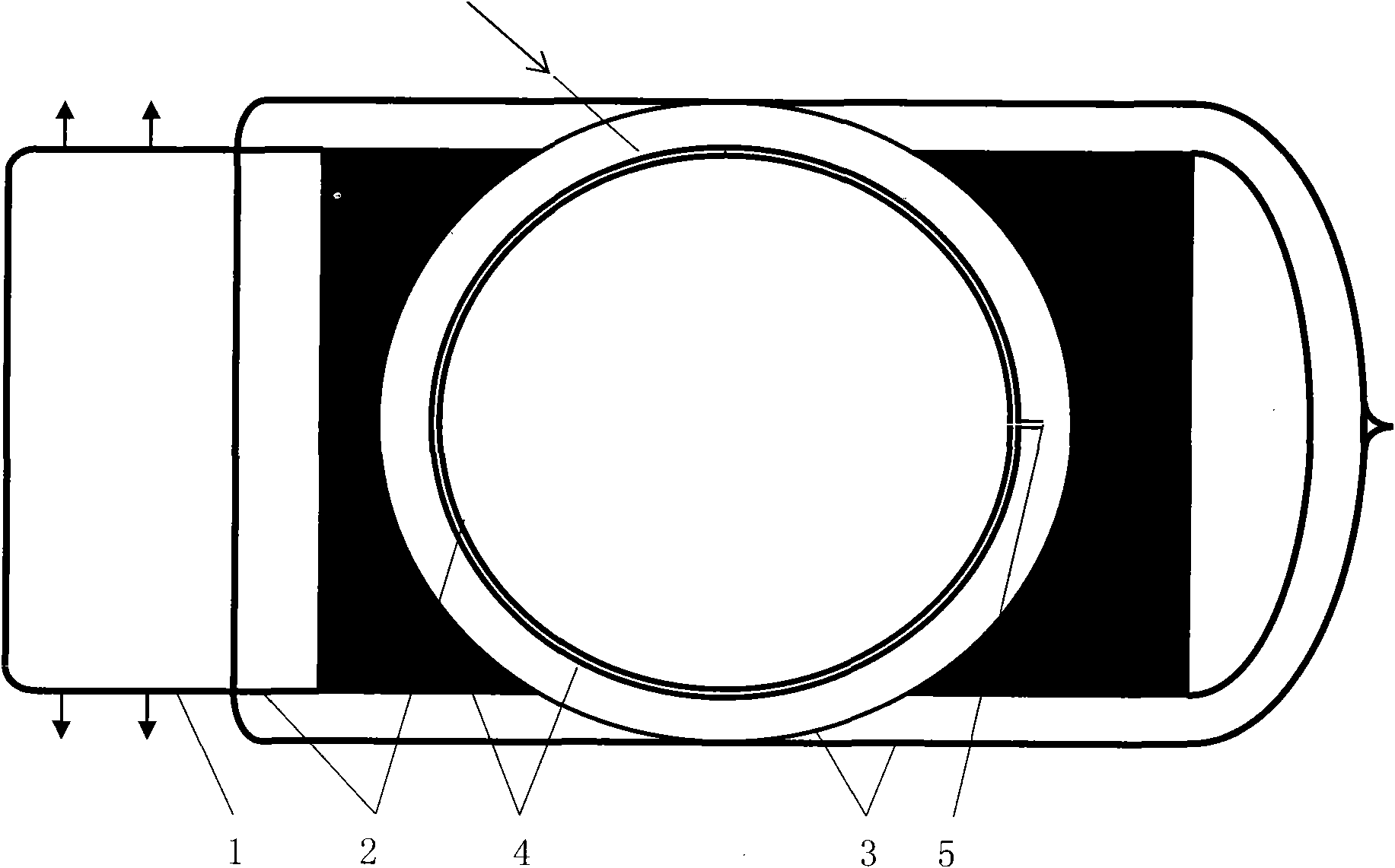

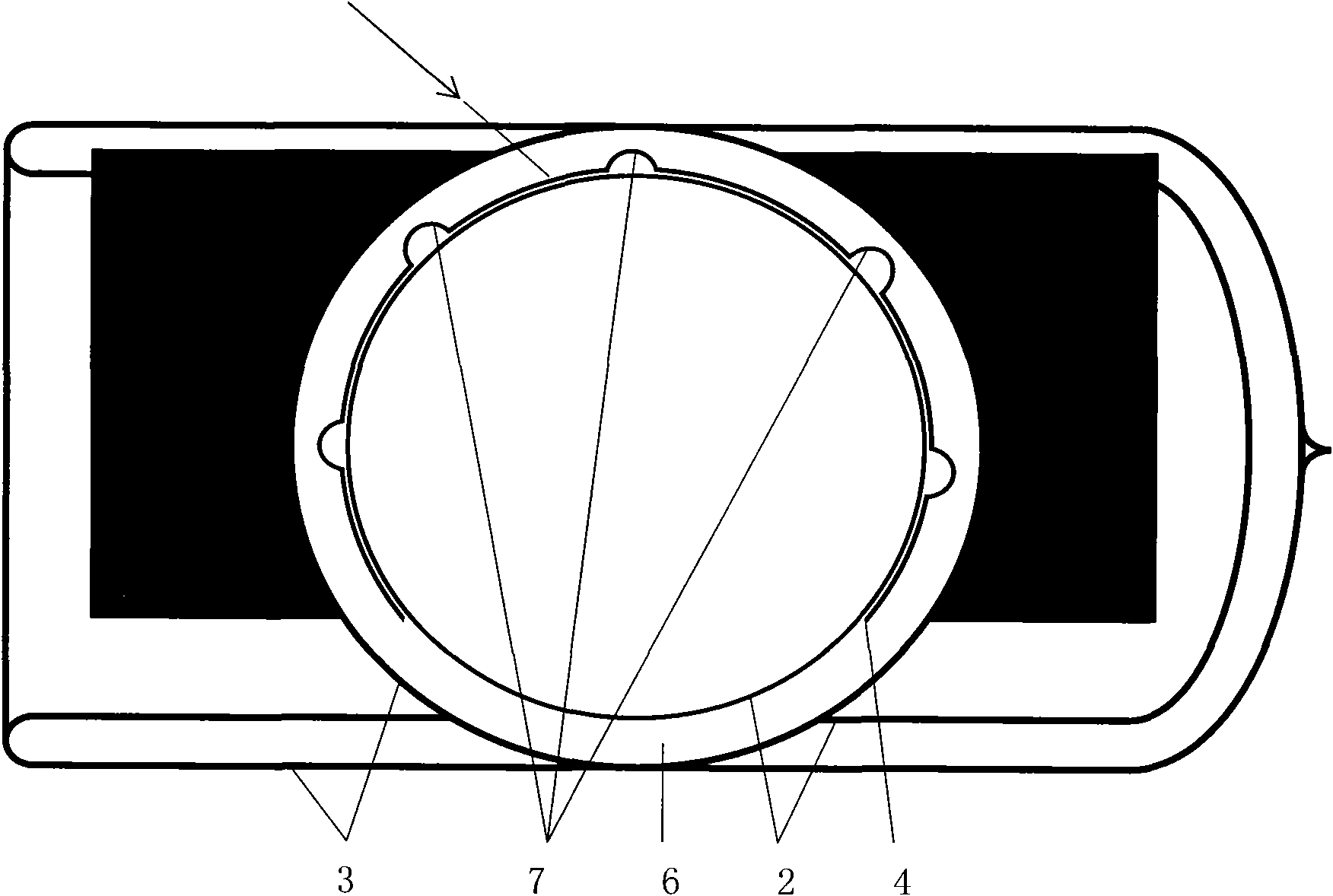

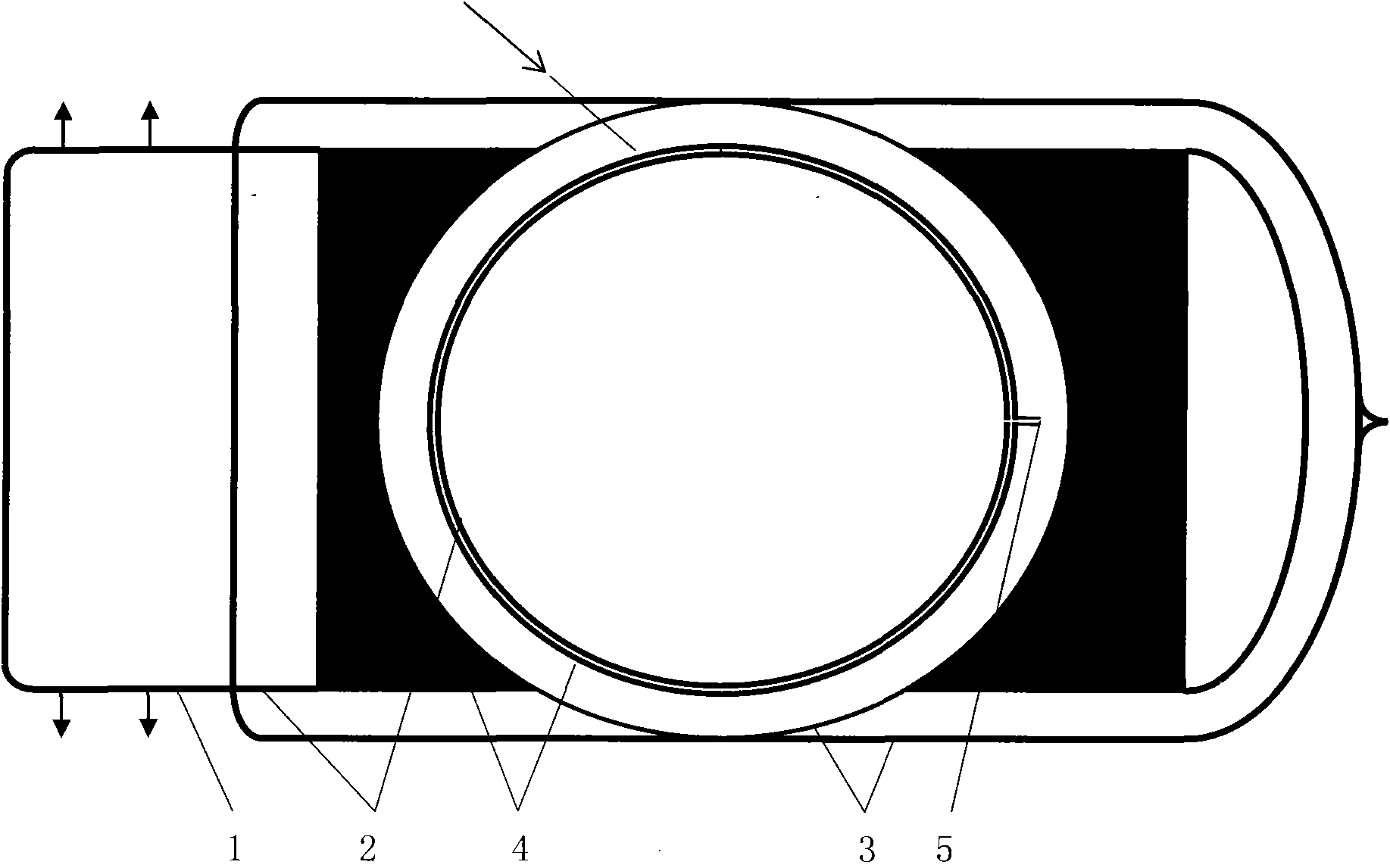

[0019] figure 1 In the process, the inner glass tube 2 and the cover glass tube 3, which also serve as the cold end 1 of the heat pipe, are melted and sealed to form a vacuum heat collecting element of the heat pipe with a selective absorption film on a slightly uneven surface. The low thermal resistance connection is closely attached to the metal coil 4 that wraps the inner glass tube 2, and a slightly uneven surface selective absorption film is formed on it, and each of its two straight sides contains a section of folded plate 5. The two sections of the folded plate 5 can be connected by resistance welding and stitch welding, so that the coiled plate 4 is 360°. The inner glass tube 2 is completely wrapped by the circumferential corners. It is required that the edge of the coiled plate 4 is not in contact with the cover glass tube 3 after welding. Welding can form a greater pressure of the coiled plate 4 on the inner glass tube 2, which helps to reduce the thermal resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com