Drive circuit for load current of high-power controllable LED

A load current and drive circuit technology, applied in the field of high-power controllable LED load current drive circuits, can solve problems such as failure, affecting LED reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

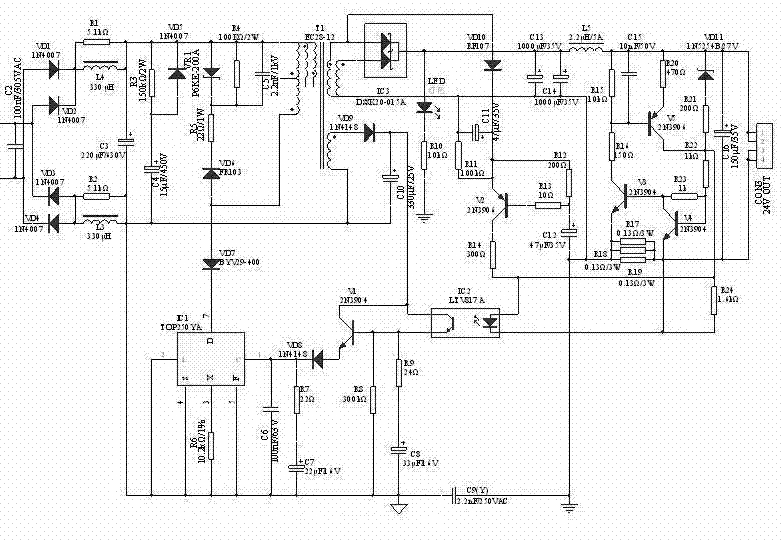

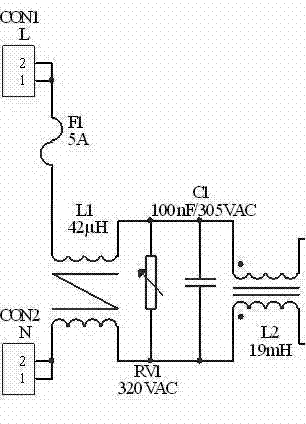

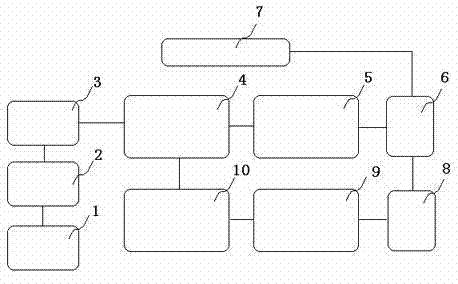

[0027] Such as figure 1 As shown, a high-power controllable LED load current drive circuit is characterized in that: a high-power controllable LED load current drive circuit at least includes: EMC and surge current control circuit 2, a primary rectification and filter circuit 3. Single-ended flyback DC / DC power converter 4, secondary rectification and filter circuit 5 and constant current and constant voltage output circuit 6, the constant current and constant voltage output circuit 6 is electrically connected to the two electrodes of the LED array 7, It is characterized in that an overcurrent, overvoltage, overheat and undervoltage signal sampling circuit 8, a photoelectric coupling isolation circuit 9 and Over-current, over-voltage, over-heat and under-voltage protection circuit 10, over-current, over-voltage, over-heat and under-voltage signal sampling circuit 8 amplifies the over-current, over-voltage, over-heat and under-voltage signals and passes them through the photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com