Flushing arrangement for WC, and method of operating such flushing arrangement

A flushing device and a technology for flushing water tanks, which are applied to flushing equipment with water tanks, water supply devices, and indoor sanitary plumbing installations, etc., which can solve the problems of reduced acceleration of jet nozzles, and achieve the effects of small deflection, stable pulses, and small turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

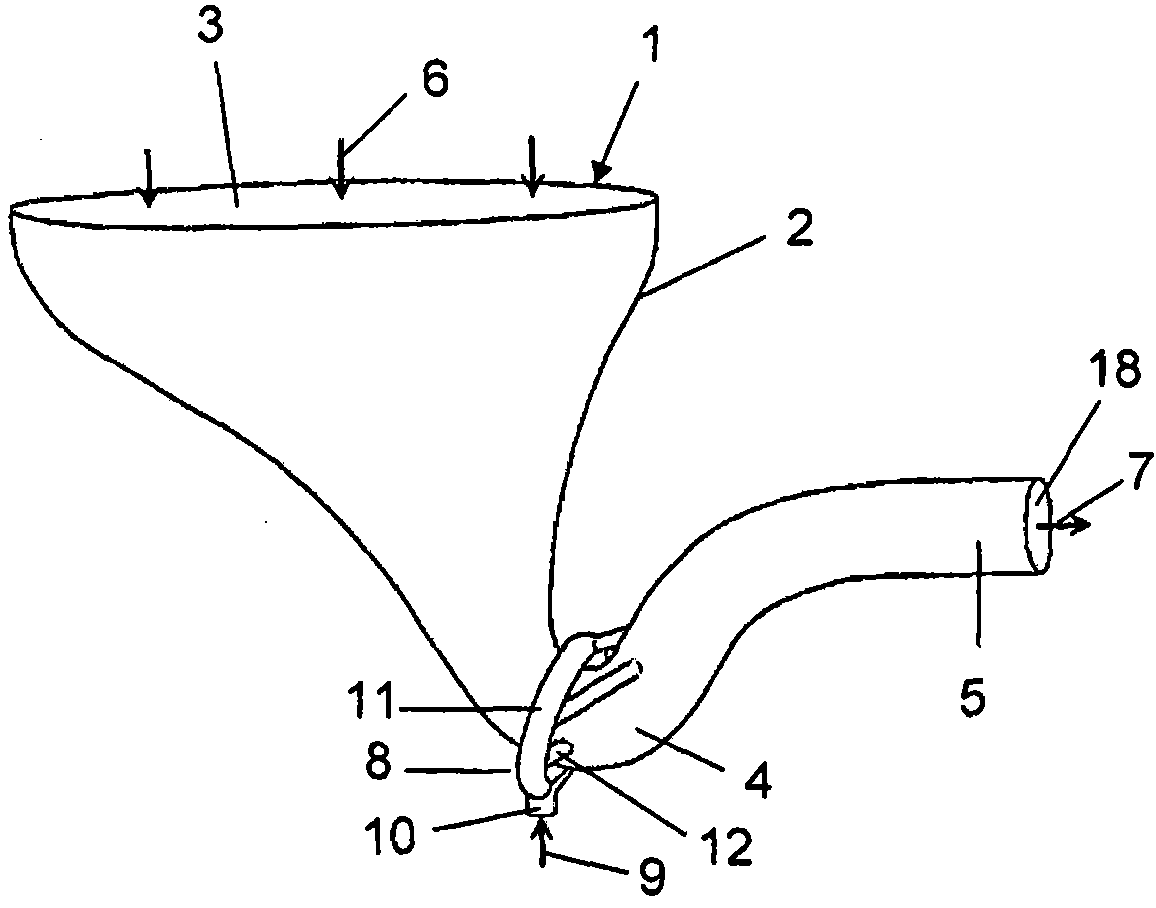

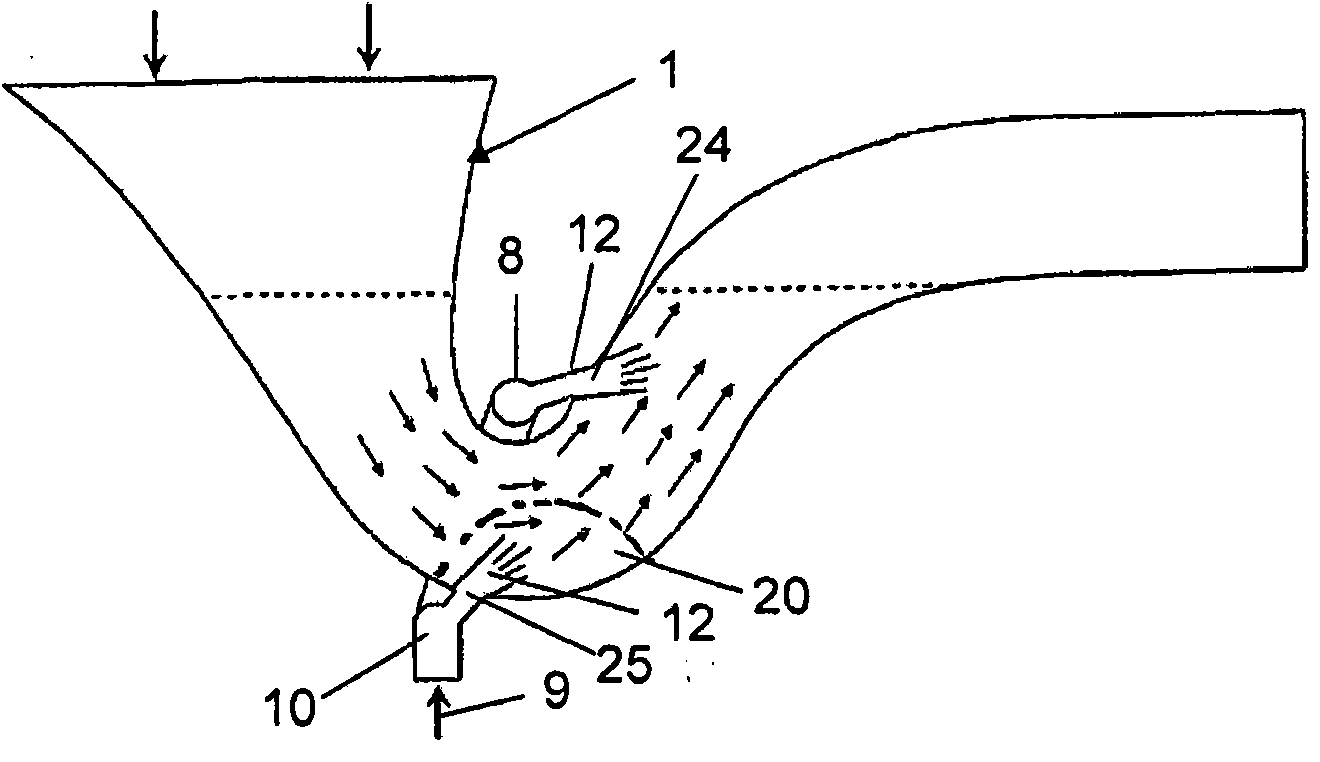

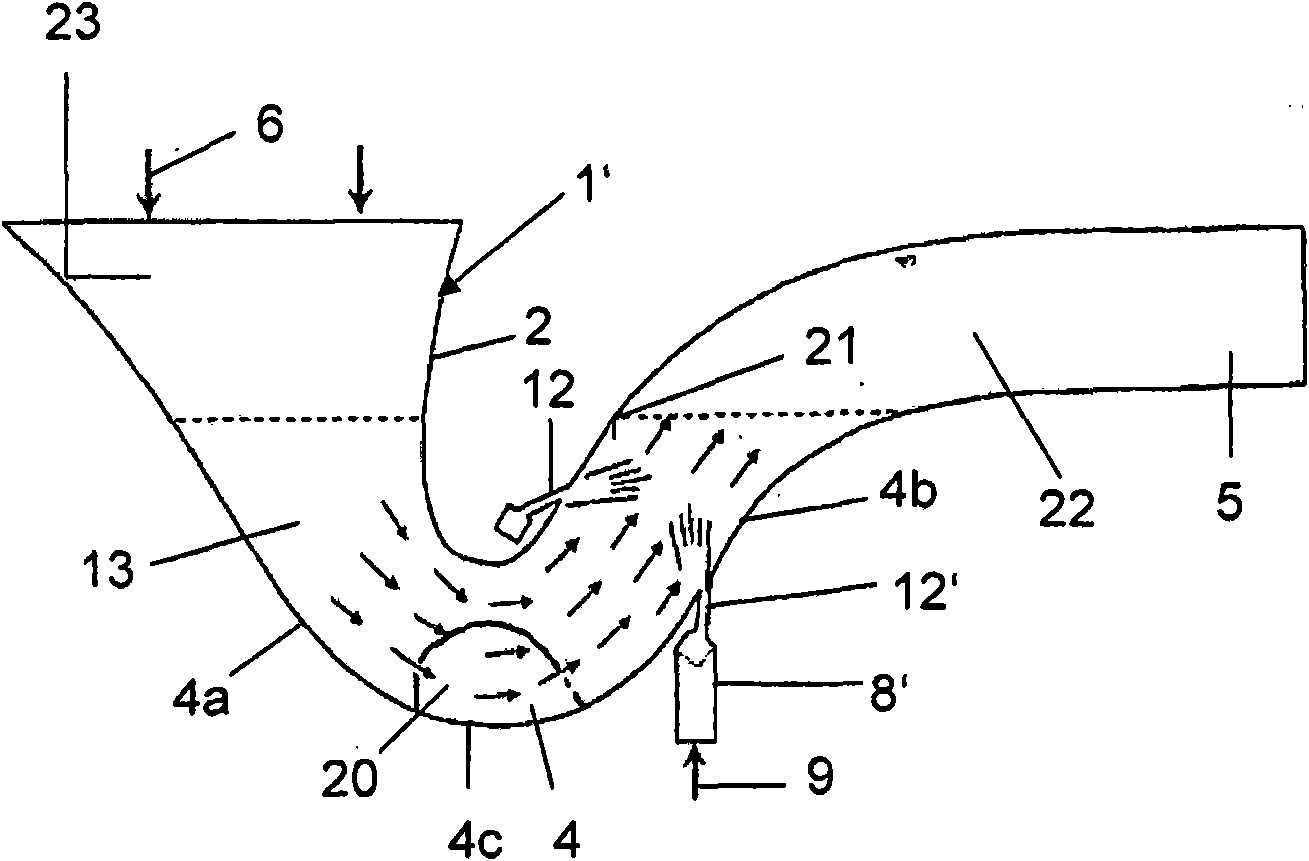

[0023] figure 1 and 2 The flushing device 1 shown in has a WC toilet 2 , for example made of ceramic material, with an inlet 3 and an outlet 18 . The inlet 3 and the outlet 18 have arranged between them a U-shaped bend 4 in which water 13 is stored so as to form an air trap. An outlet 18 is arranged at the end of a waste pipe 5 which is connected to a treatment line in the usual manner. During rinsing, water is supplied in the direction of arrow 6 as is the case in a normal rinsing channel (not shown here). Furthermore, the water 13 present in the U-bend 4 is accelerated by the pulse nozzle arrangement 8 . The pulse nozzle arrangement 8 serves to generate a plurality of flow cones 15 in the water 13 , which are directed towards the outlet 18 . Via the flow cone 15 , the water present downstream of the pulse nozzle arrangement 8 is pushed towards the interior 22 of the waste pipe 5 , thus upwards towards the outlet 18 . Thus, the remainder of the water 13 present in the U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com