Sister connector

A connecting piece and ring piece technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of poor reliability, inapplicability, poor sealing stability, etc., and achieves installation convenience and precision. Less convenience, guaranteed stability and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

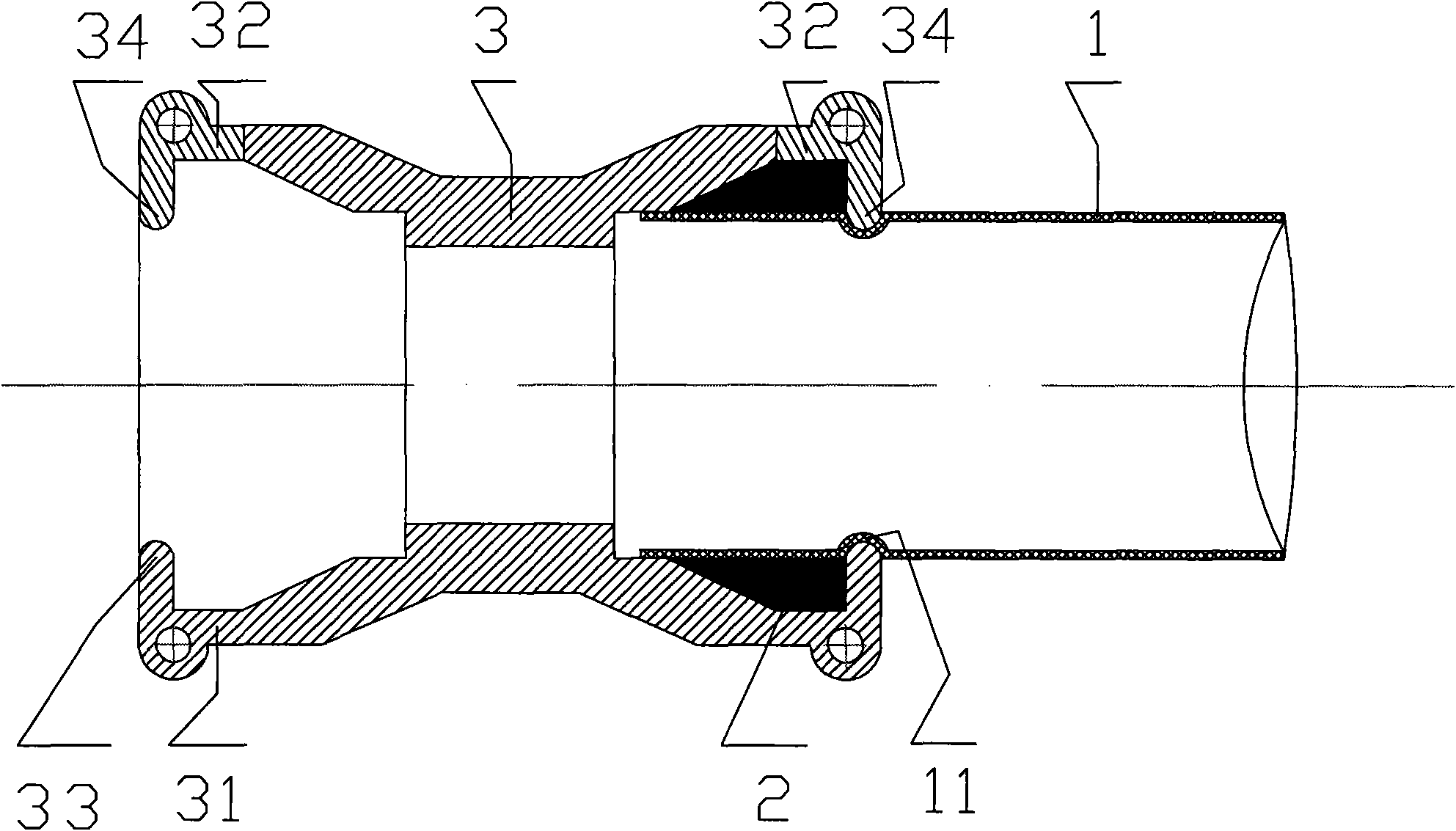

[0015] see figure 1 , and combined with figure 2 and image 3 , figure 1 It is a structural cross-sectional view of this embodiment after the assembly is completed;

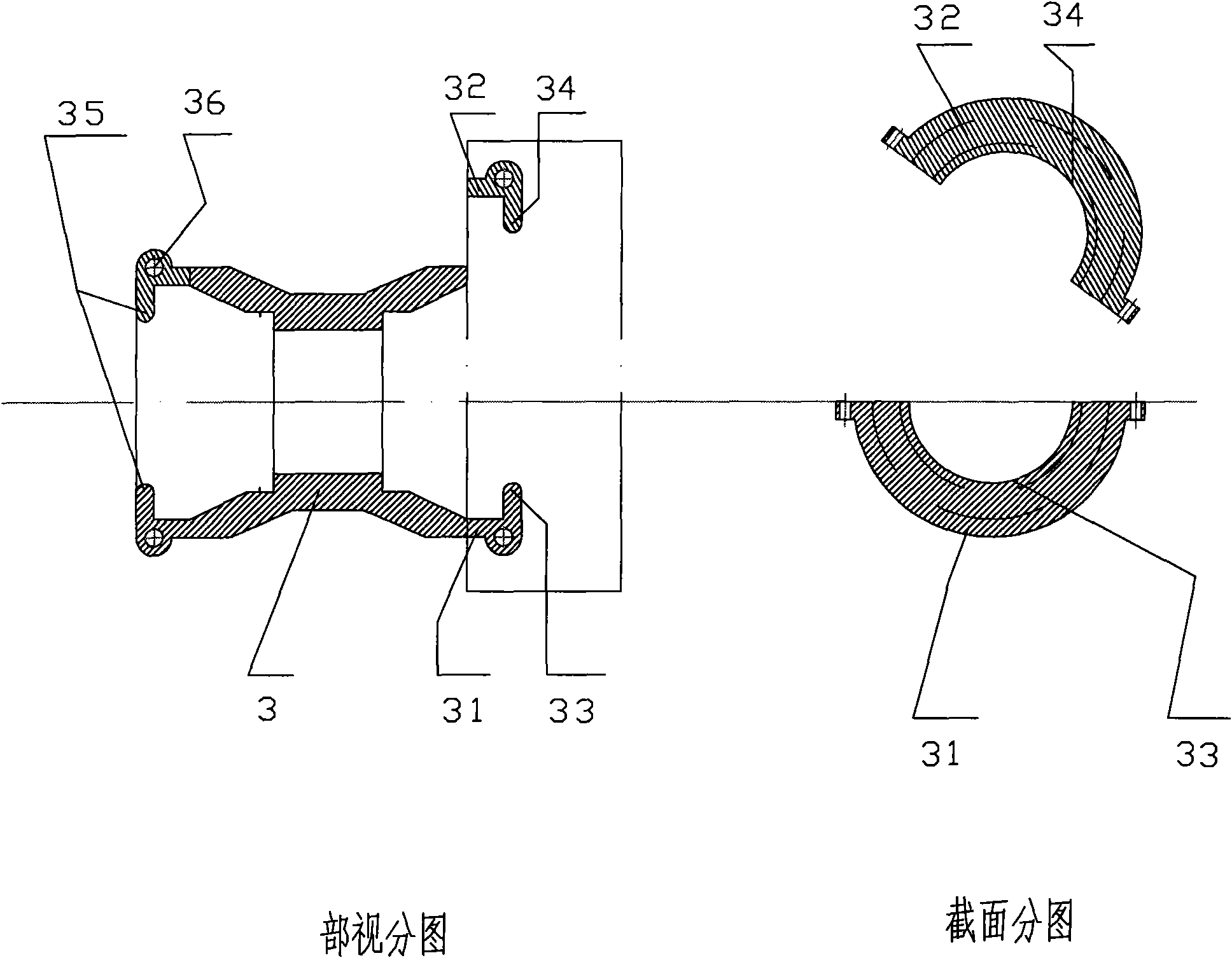

[0016] figure 2 It is a detailed illustration of the connection end of this embodiment. The cross-sectional view in the figure shows the schematic diagram of the connection port in the connected state and the separated state (in the frame), and the cross-sectional view in the figure shows the connector on the cross-sectional view. A cross-sectional schematic diagram of the separated end (that is, the part in the frame);

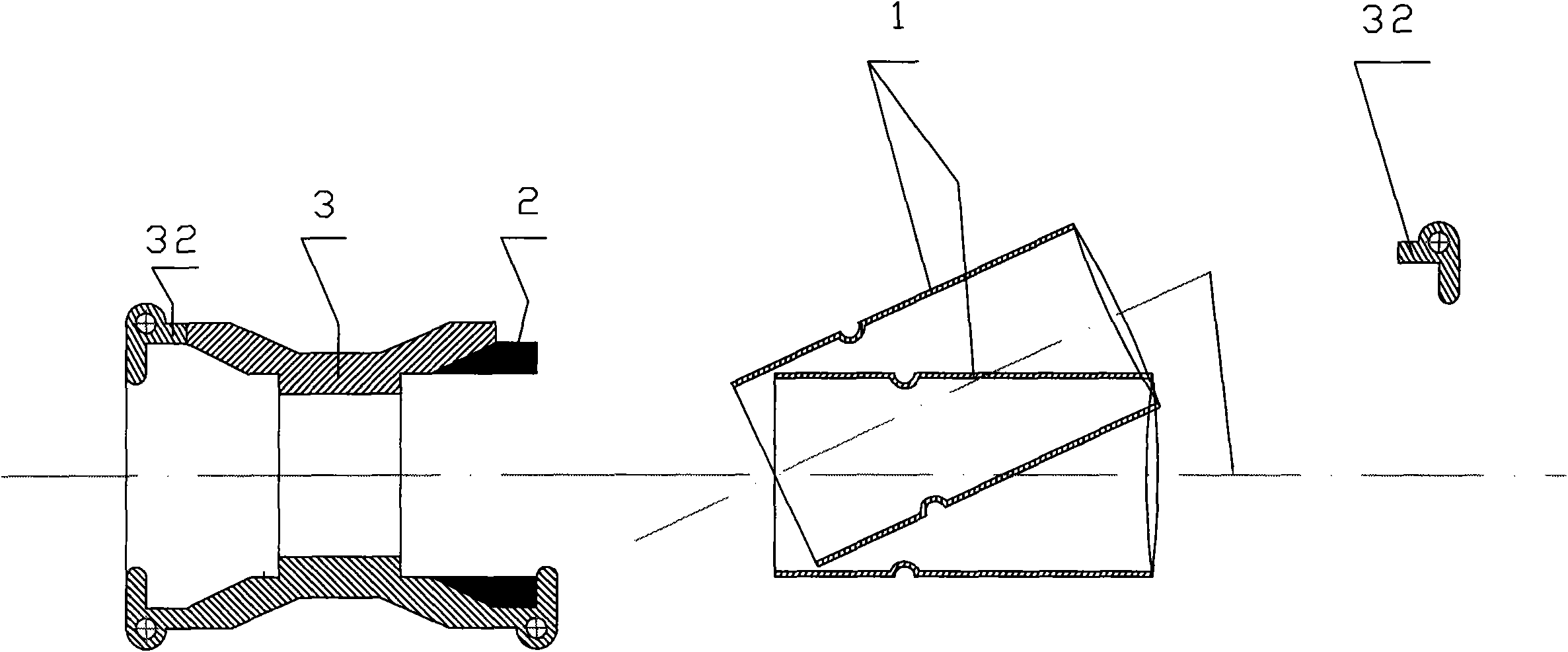

[0017] image 3 It is a cross-sectional view of each component of this embodiment when assembled;

[0018] Figure 4 It is a structural cross-sectional view of another design of the pipe body after assembly in this embodiment;

[0019] Look image 3 , recombine figure 2 , according to the assembly sequence, from left to right, there are connection 3, sealing ring 2, pipe body 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com