Pressure spring testing device

A technology of testing device and compression spring, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., which can solve the problems of unsuitable batch testing, long test cycle, low test accuracy, etc., and achieve wide application range, convenient observation and prevention Effects of disturbance and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

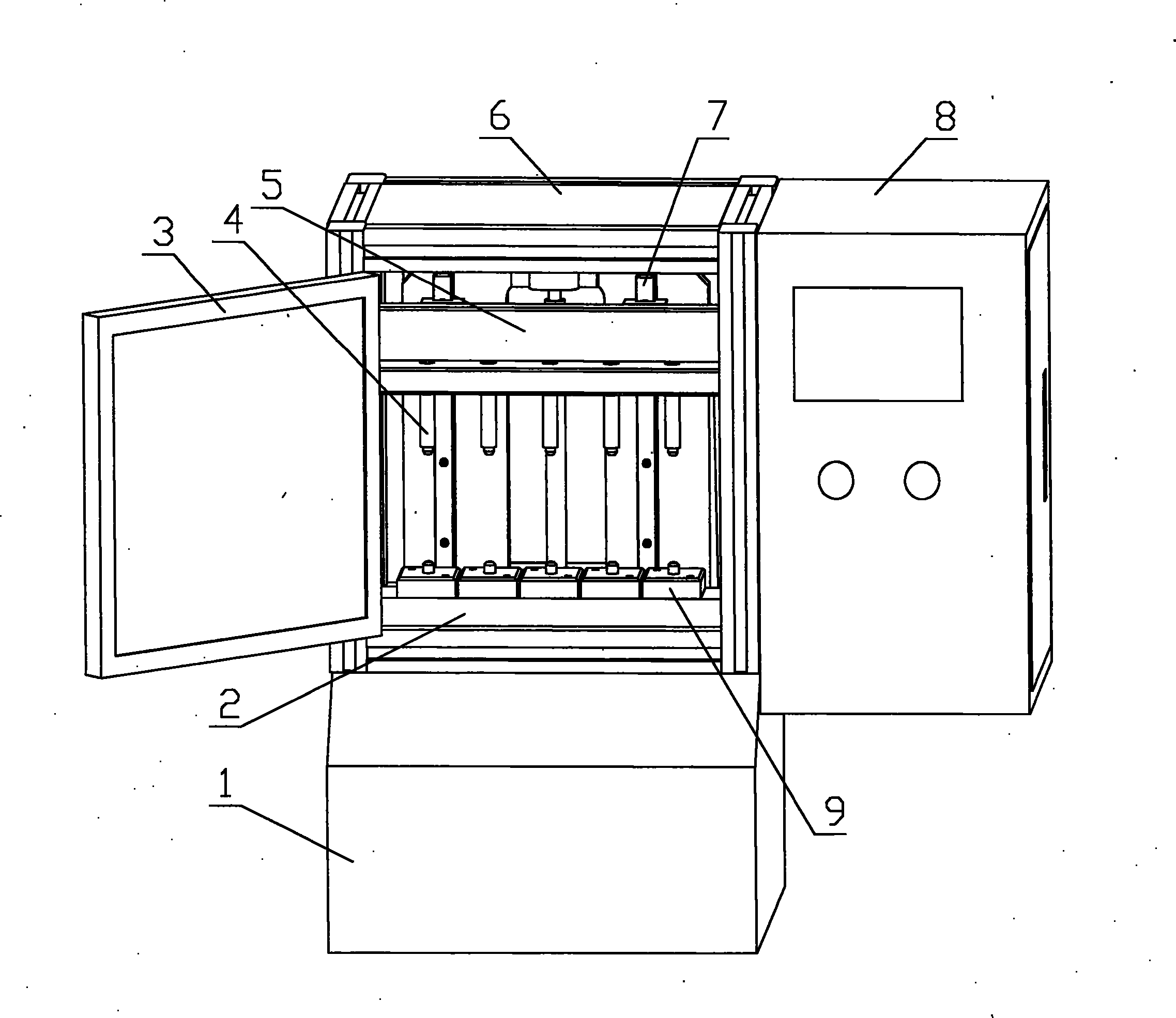

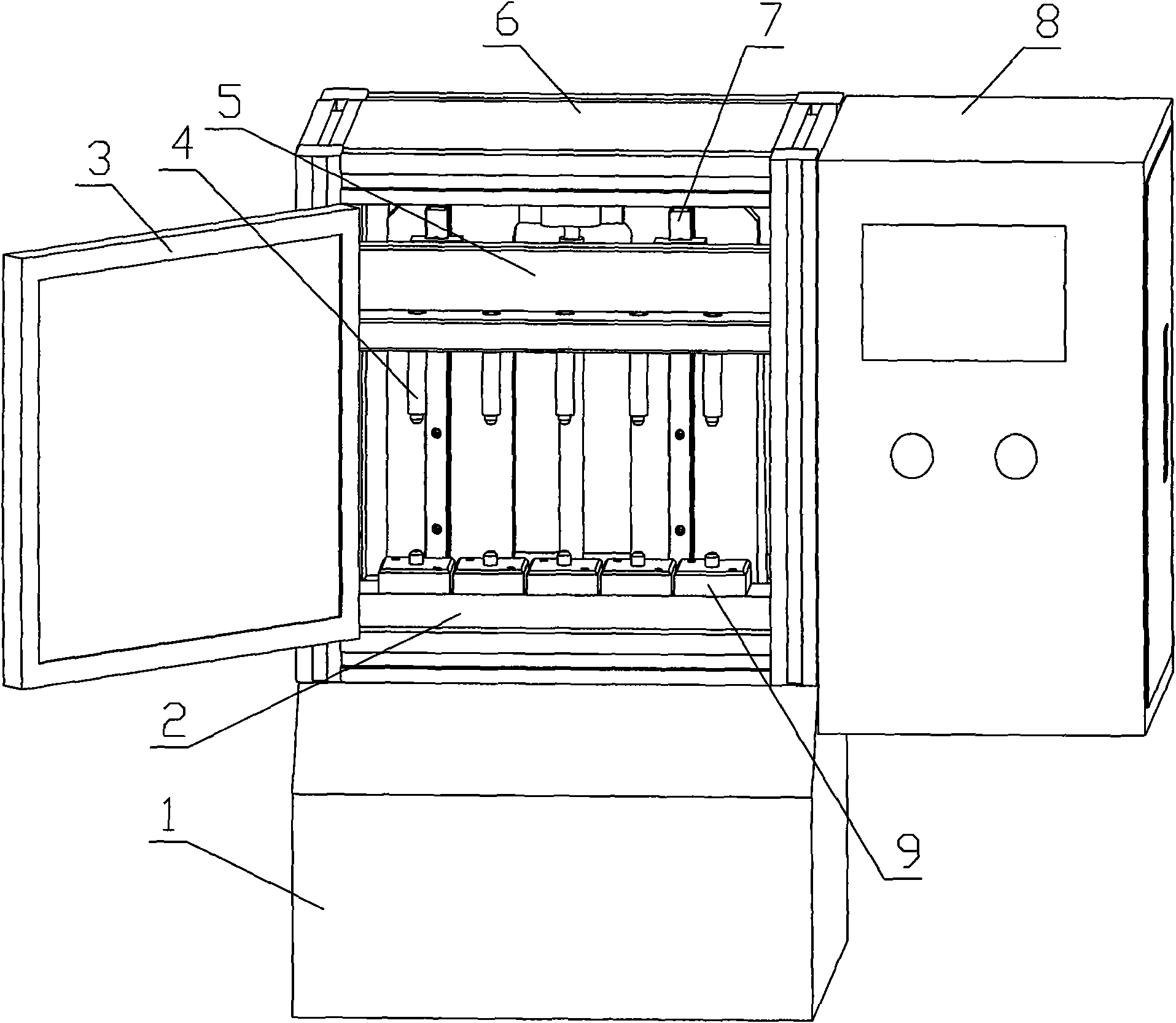

[0020] Such as figure 1 and figure 2 As shown, the present invention discloses a compression spring testing device, comprising a steel base 1, above which is a work area, outside the work area is a transparent cabinet 6 surrounded by plexiglass, the transparent cabinet 6 front and back are set as plexiglass doors 3 . The following working parts are all arranged inside the transparent cabinet body 6, so that on the one hand, it is convenient to test under isolated conditions, and on the other hand, the testing process can be monitored.

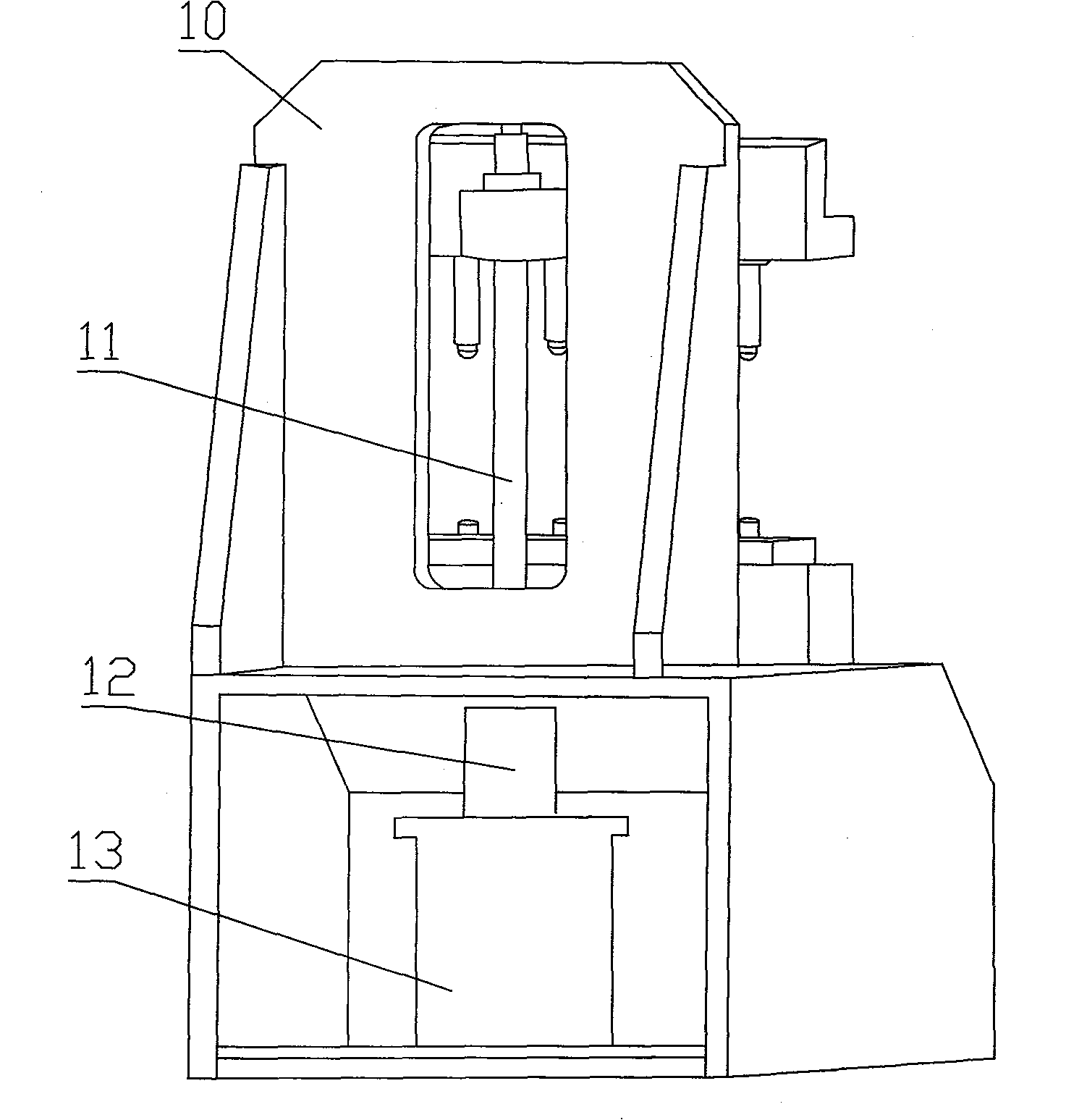

[0021] A stepping motor 13 is arranged inside the base 1 , and the stepping motor 13 is connected with a precision screw 11 through a shaft coupling 12 . The precision screw 11 is arranged above the base 1 and inside the transparent cabinet 6 . When the stepping motor 13 rotates, it drives the precision screw mandrel 11 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com