Inspection of rod-shaped articles in the tobacco processing industry

A processing industry and article technology, applied in the field of rod-shaped articles, can solve problems such as clogging the machine, and achieve the effect of improving quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

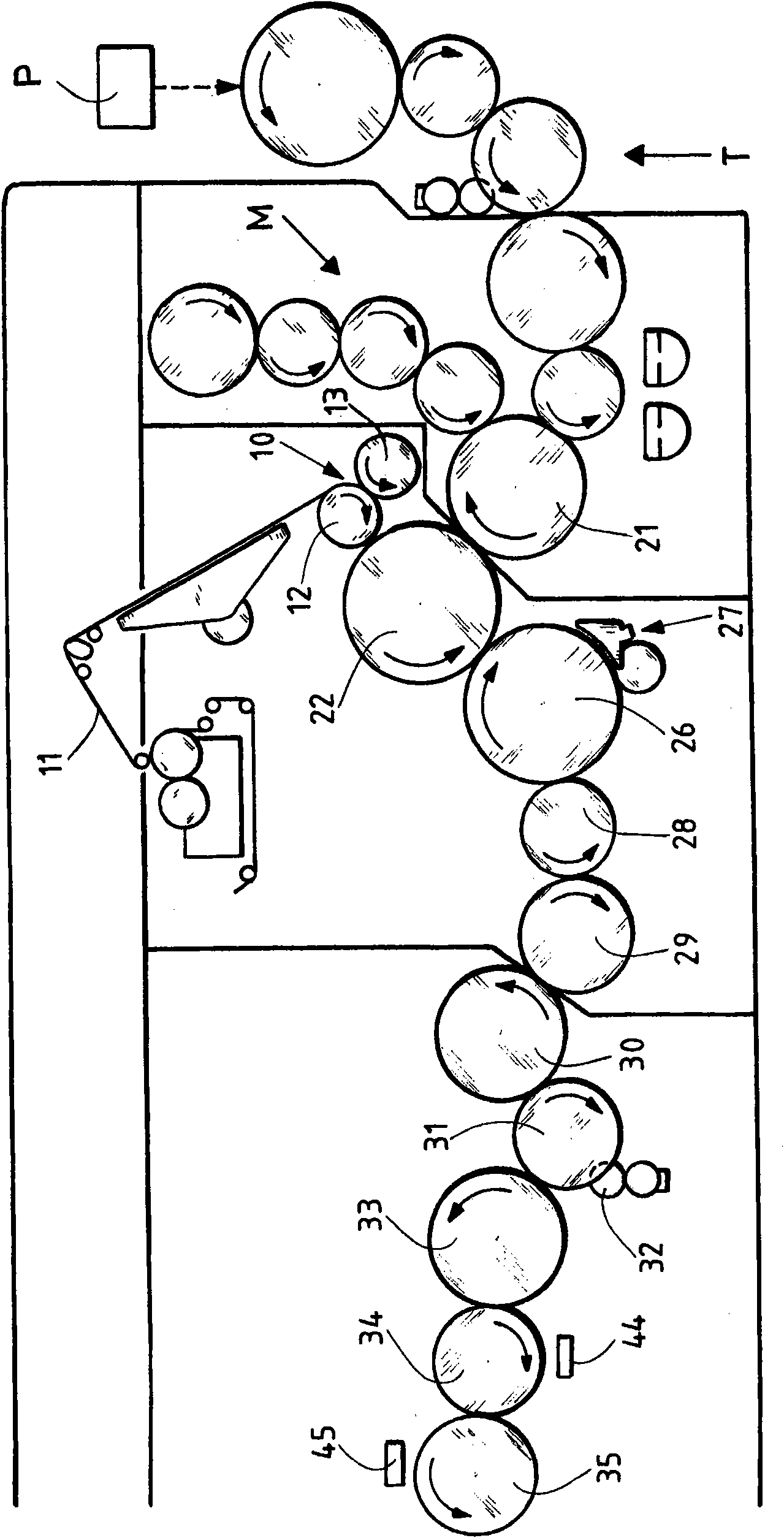

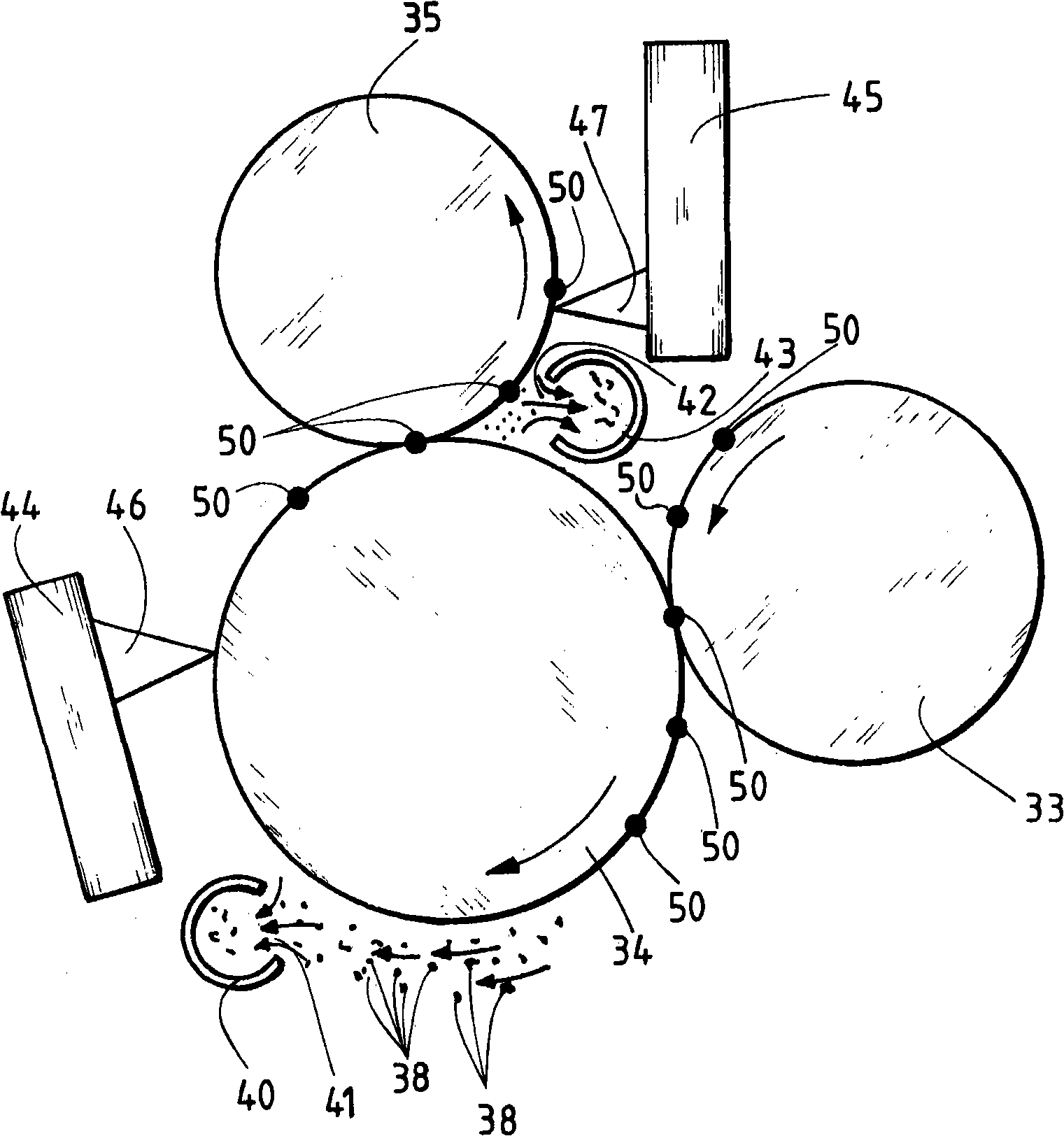

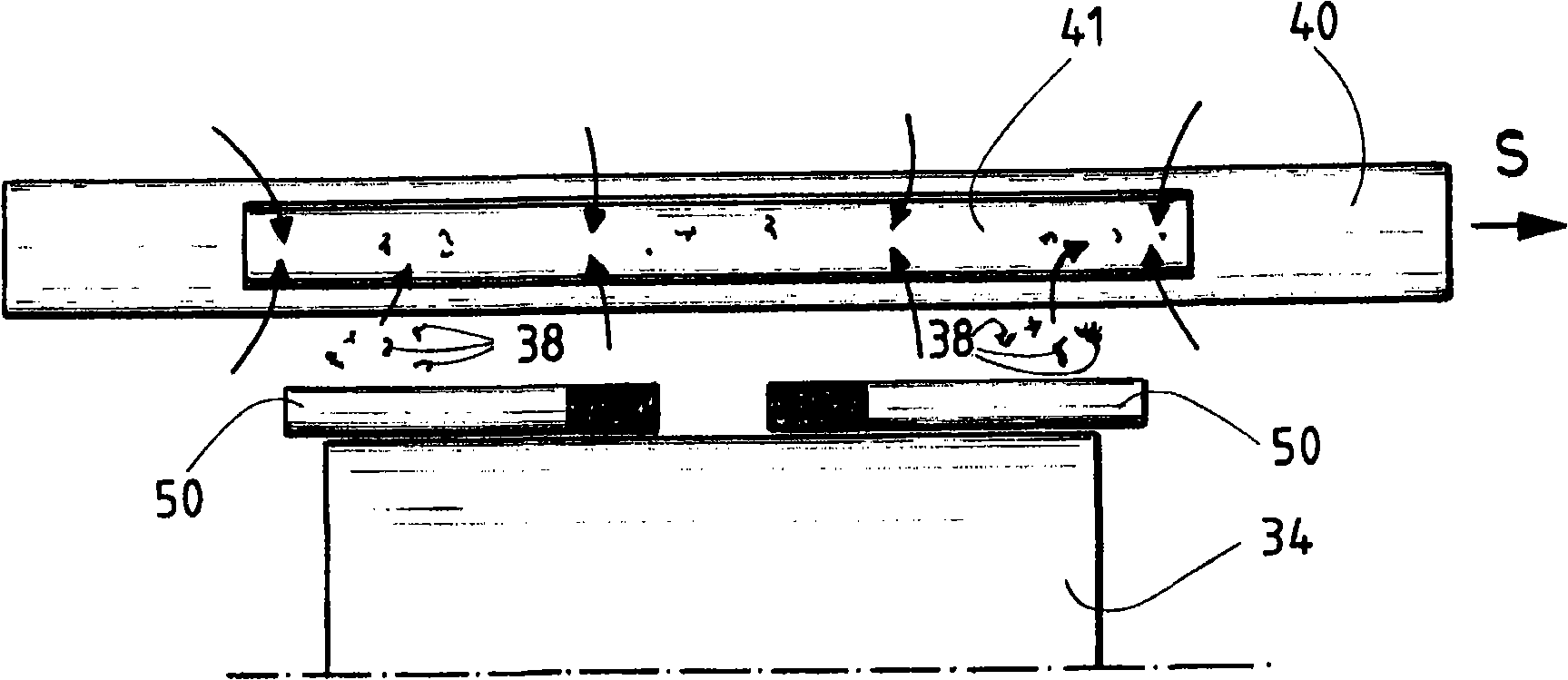

[0067] exist figure 1 , a filter tipping machine is shown partly in front view, wherein the filter tipping machine receives via a tumbler assembly T for supplying cigarettes from a schematically drawn cigarette machine P with double Double the length of use (Gebrauchslaenge) cigarettes. A cigarette making machine is known under the name "PROTOS" of the applicant of the present patent.

[0068] On its conveying path to the alignment drum 21 , the cigarettes of double usage length are severed and split longitudinally. On the alignment drum 21 , a double-length filter plug is conveyed via a further drum assembly M, which is accordingly sandwiched between two cigarette rods spaced apart longitudinally and axially. As a result, a series of cigarette / filter plug / cigarette groups arranged one behind the other in the transverse direction is formed on the alignment drum 21 .

[0069] The aligned groups of articles (Artikelgruppen) are delivered by the alignment drum 21 to the delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com