Miniature image capture lens

An image and lens technology, applied in the field of wafer-level miniature image extraction lens, to achieve the effect of short track length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The implementation examples of the present invention are described below, which disclose the main technical features of the present invention, but are not intended to limit the present invention.

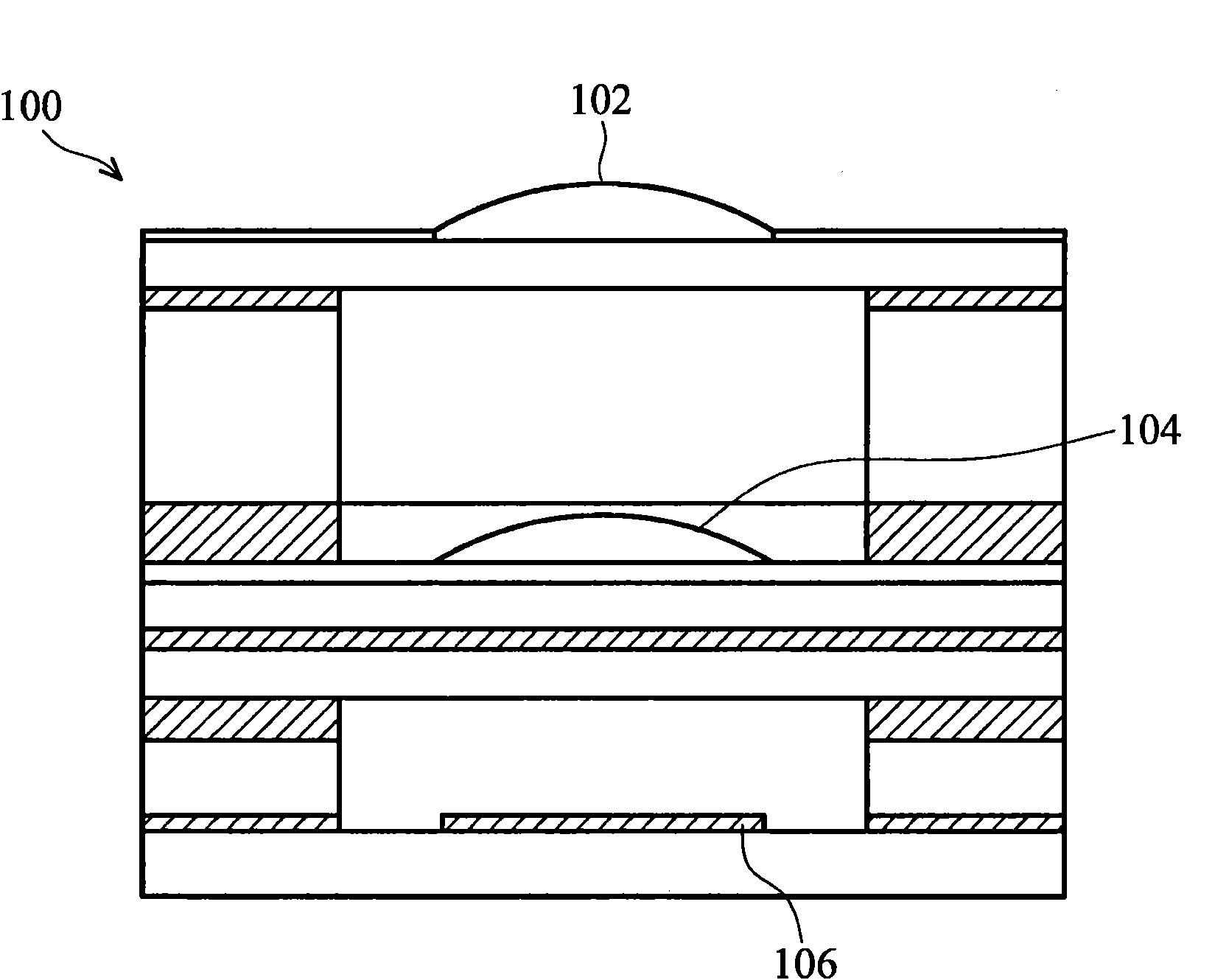

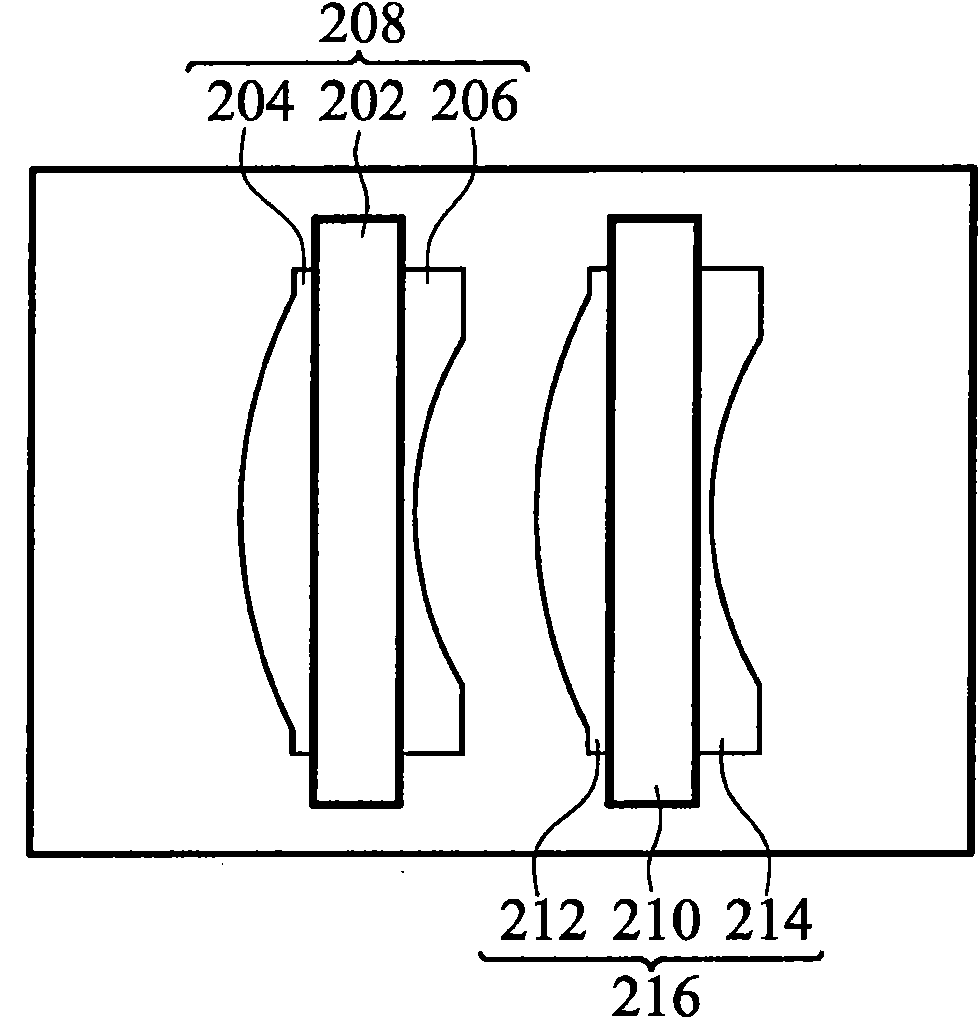

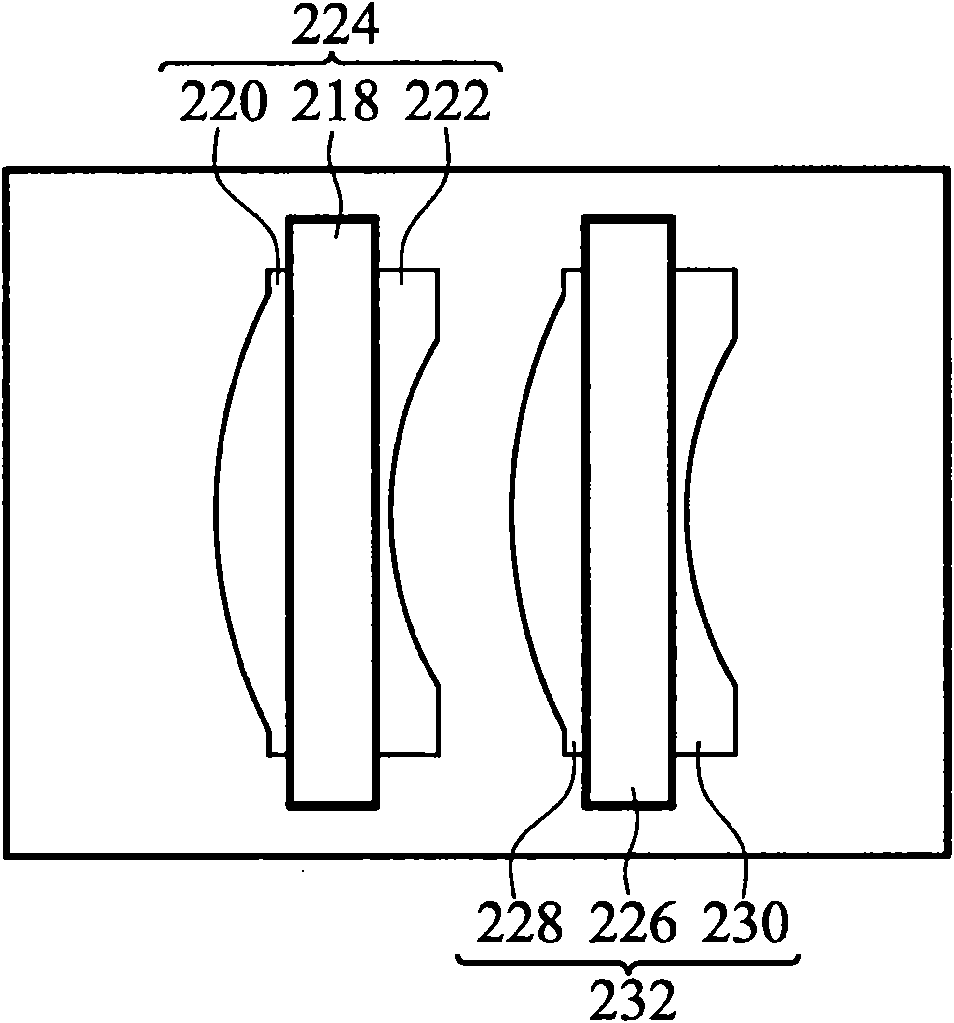

[0075] The present invention discloses a wafer-level lens system comprising two optical surfaces on opposite sides of a glass substrate. In the present invention, the two optical surfaces of the lens may be composed of different materials, one of which has a high refractive index and the other has a Low refractive index, the lens material can be ultraviolet (UV) curable polymer compound. In addition, the two-side wafer-level lens provided by the present invention has high refractive index and low refractive index respectively on the surfaces on both sides, and the wafer-level lens provided by the present invention has convex and concave surfaces on both sides respectively. to minimize optical scatter. Please note that in the present invention, different materials can be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com