High-efficiency cotton picker head

A high-efficiency technology for picking cotton, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of reducing production, polluting the environment, and high impurities, and achieves the effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

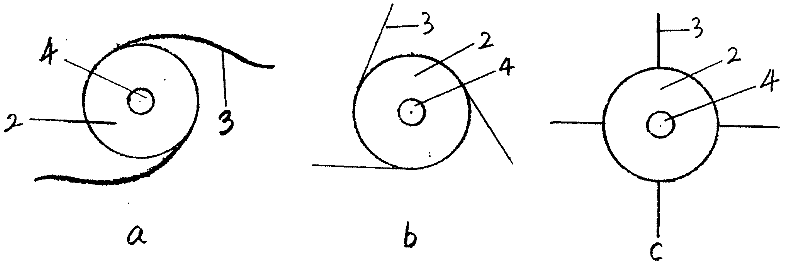

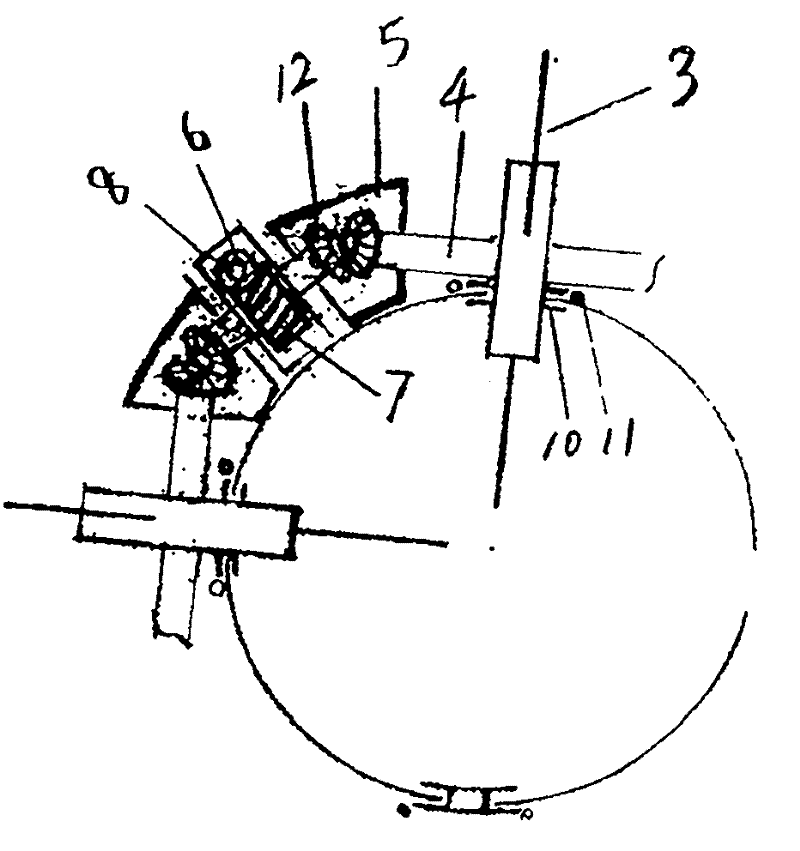

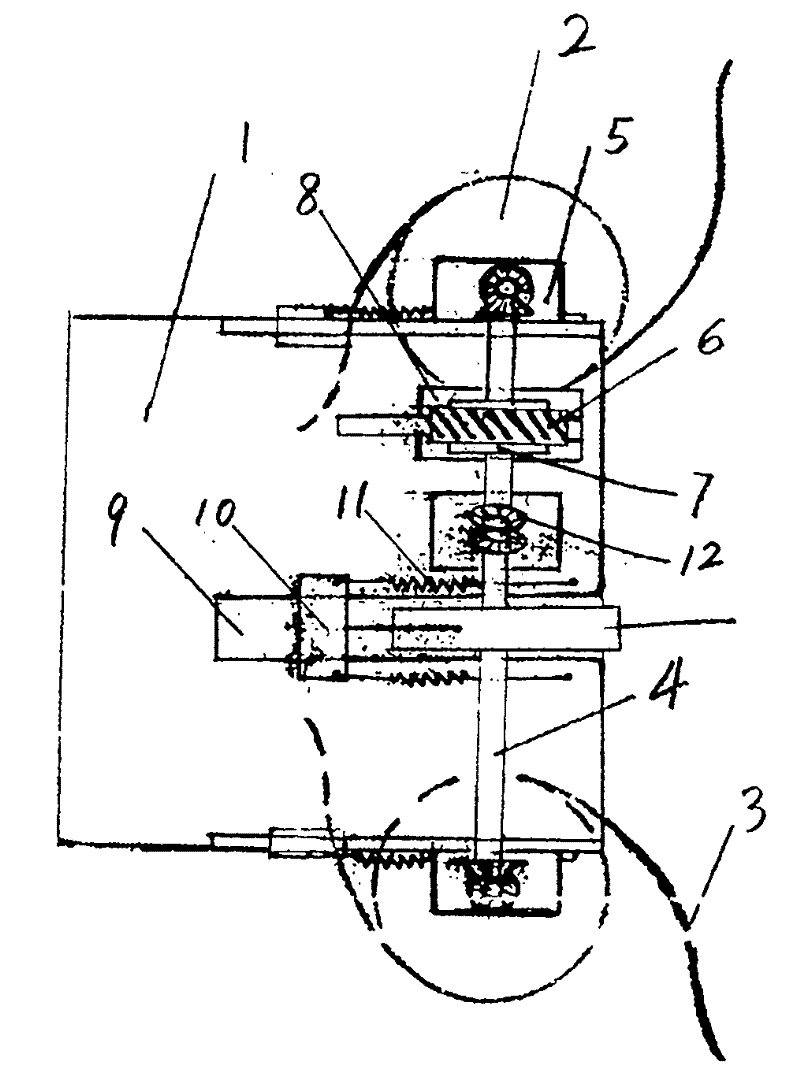

[0011] A number of support frames (5) are fixed around one end of the hard pipe material (1). The support frame is equipped with a cotton picking claw assembly. The cotton picking claw assembly is composed of a base circle body (2), a cotton picking claw (3), The cotton claw shaft (4) is composed of a cotton claw shaft (4), and its shape is characterized as follows: a cotton claw shaft (3) is arranged on the outer circle of the base circle with the cotton claw shaft (4) fixed in the center, and each cotton claw shaft is connected by a connecting piece. (12) The connection is linked to each other, and a chute (9) is opened in each cotton picking claw corresponding to the mouth of the hard pipe material, and a slider (10) is placed in each chute, and the slider is connected to the The mouth of the hard tube material forms a cotton doffing device. When the cotton picking claw turns to the slider, the spring and the slider are combined to generate and maintain a certain pressure on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com