A kind of method for preparing high-concentration magnesium chloride solution by continuous dissolving of bischofite in salt lake

A magnesium chloride solution and bischofite technology, applied in the field of salt chemical industry, can solve the problems of lagging halogenation speed, stop production, high cost, etc., achieve the effect of automatic control, continuous mechanical feeding, and improve labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

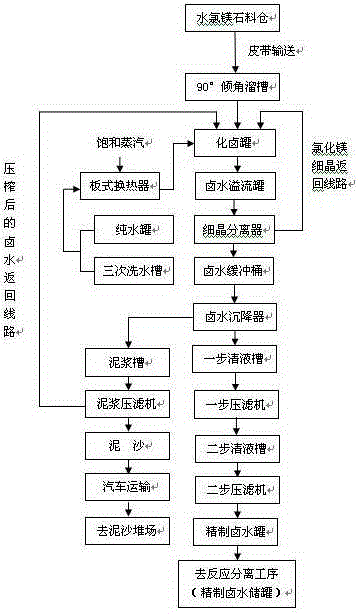

Method used

Image

Examples

Embodiment 1

[0068] After several years of industrial test research and continuous improvement and optimization of the process in the long-term practice process, the present invention has now summed up a method for preparing a high-concentration magnesium chloride solution by continuously dissolving bischnite in salt lakes. The research process over the past few years is listed as follows:

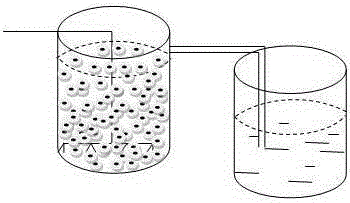

[0069] From October 2006 to October 2009, when the 5,000 tons / year high-purity magnesium hydroxide industrial test device in the Xitieshan test workshop was in operation, the dissolution of bischofite in the brine preparation process used a concrete-lined glass fiber reinforced plastic dissolution tank. Compressed air was used to stir and dissolve.

[0070] After the car transports the raw bischofite to the workshop, it is directly poured into the dissolution tank, then water is added, and then stirred with compressed air regularly or irregularly. Although this method reduces the labor intensity of wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com