A curved grid plate re-cleaning type three-cylinder sieve oat cleaning device

A cleaning device and grid plate technology, applied in threshing equipment, agriculture, application, etc., can solve the problems of increasing the impurity rate of oat grains, increasing the impurity rate, and increasing the loss rate, so as to reduce the cleaning impurity rate , Increase the screen area and reduce the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

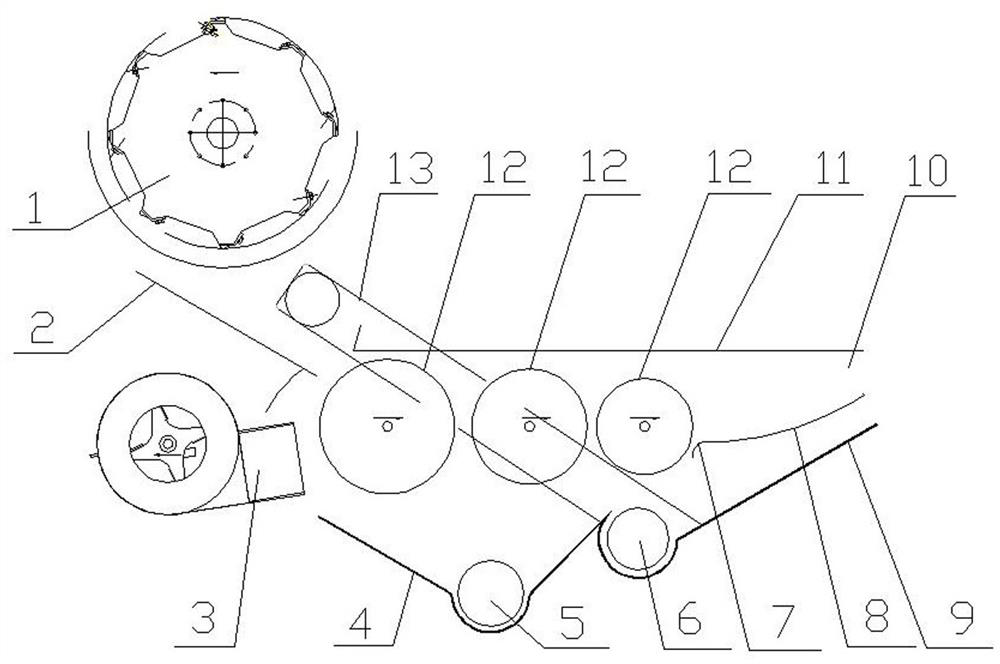

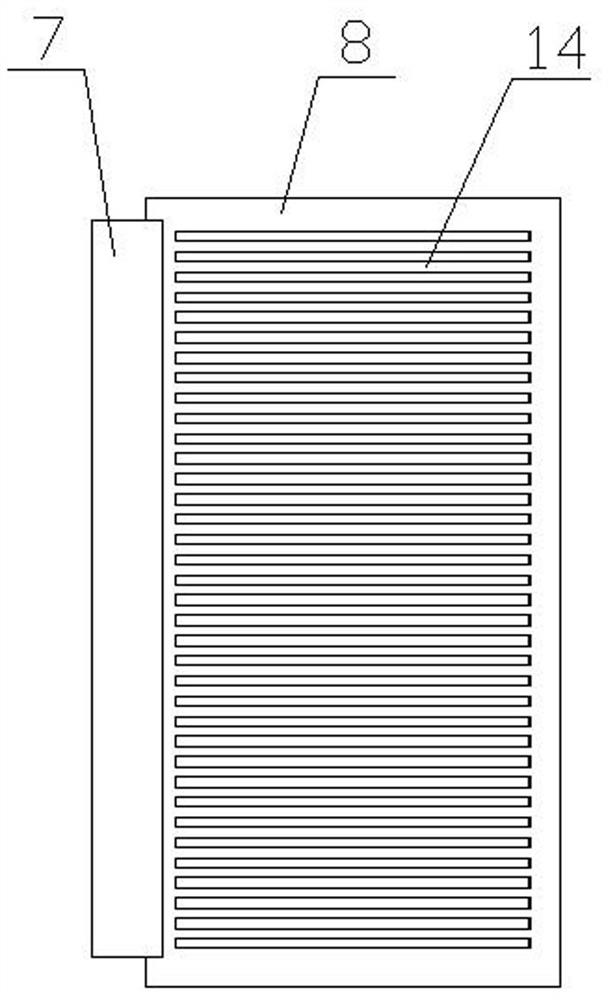

[0023] Such as figure 1 As shown, a kind of curved grid plate re-cleaning type three-drum sieve oat cleaning device of the present invention comprises a casing 11, a three-drum sieve cleaning device which is arranged in the casing 11 and is used for oat grain cleaning. Separating mechanism, grained bar drum type threshing mechanism for feeding materials to the three-drum sieve type cleaning mechanism 1, re-selecting part of the sieves screened out by the three-drum sieve 12-type cleaning mechanism selection mechanism and collection mechanism for oat kernel collection.

[0024] The three cylinder screen 12-type cleaning mechanism includes a blower fan 3 arranged at the left end of the casing 11, a miscellaneous discharge port 10 provided at the right end position of the casing 11, and a rotary arrangement in the casing 11 between the blower fan 3 and the miscellaneous discharge port 10 Between the three cylinder sieves 12. The diameters of the three cylindrical screens 12 dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com