Continuous casting breakout prediction method based on neural network

A neural network and breakout technology, applied in the field of metallurgical casting, can solve the problems of low breakout prediction accuracy, and achieve the effects of improving the recognition effect and prediction accuracy, reducing the false alarm rate and omission rate, and improving the calculation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

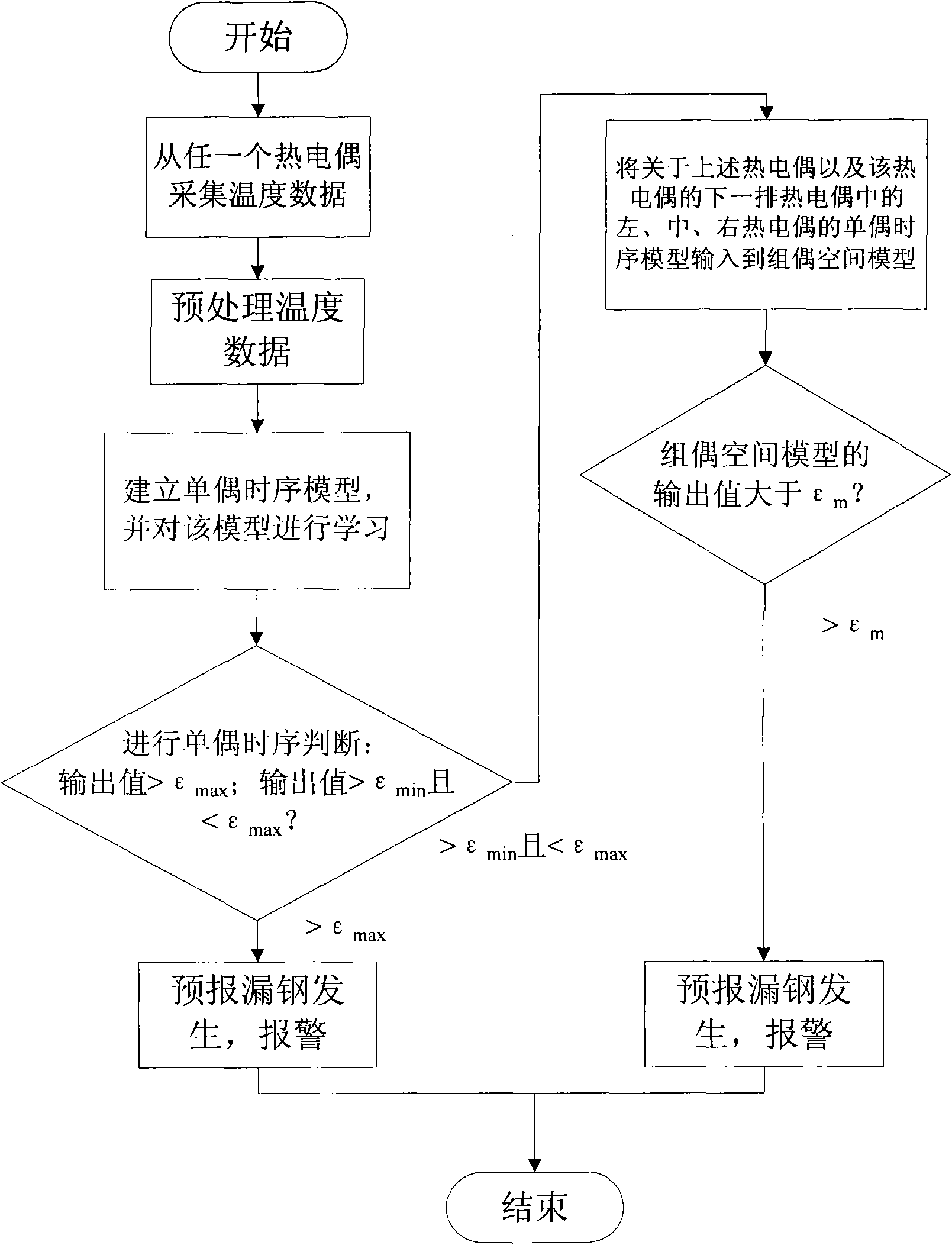

[0014] Such as figure 1 As shown, according to an embodiment of the present invention, the continuous casting breakout prediction method based on neural network may include:

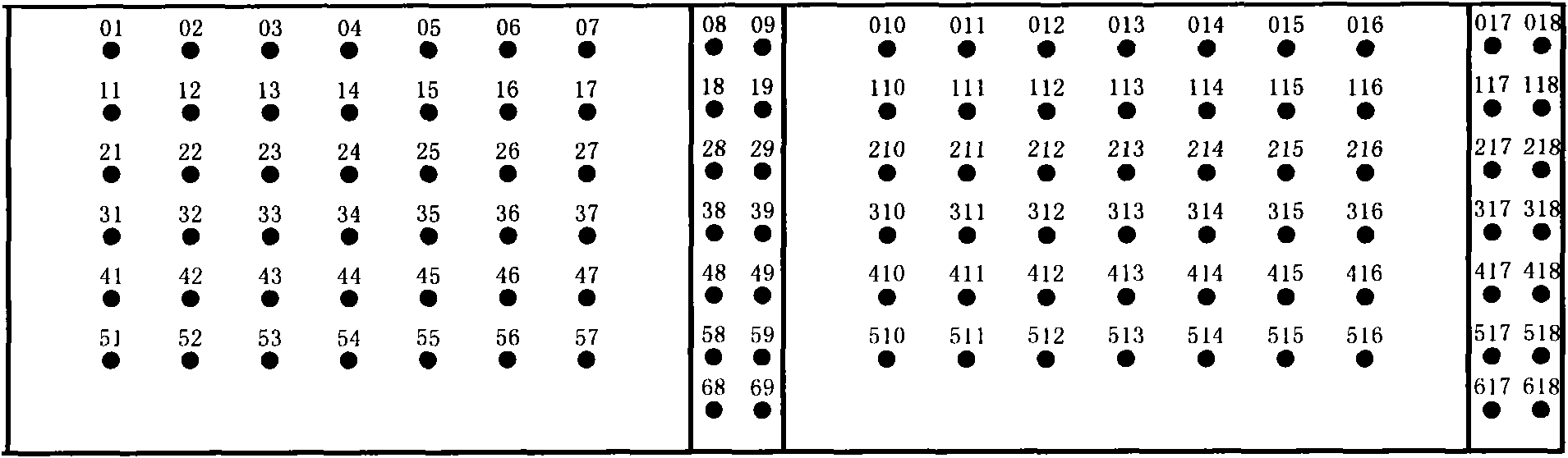

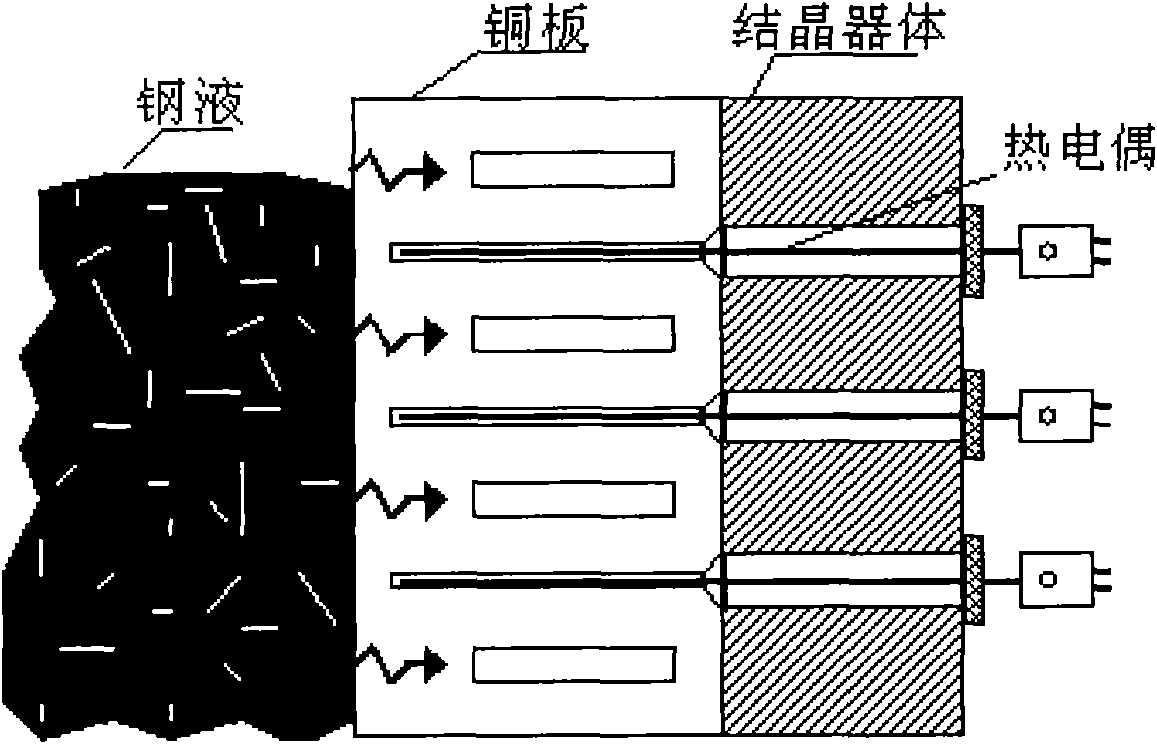

[0015] Step 1: Collect the temperature data of the thermocouples in the continuous casting site online and store the temperature data. Such as Figure 2-3 As shown in , there are multiple thermocouples arranged in a matrix on the mold of the continuous casting machine, such as figure 2 exemplarily shows that 6 rows and 7 columns are installed on the two wide sides of the crystallizer (including the fixed side and the movable side), and 7 rows and 2 columns are installed on the two narrow sides of the crystallizer, and the thermocouples are evenly distributed, In this way, a total of 112 thermocouples cover the entire crystallizer copper plate, which can realize the temperature detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com