Annular automatic sheet grinding machine

A ring-shaped, automatic technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of frequent replacement of coarse and fine grinding discs, achieve the effect of simple structure, convenient operation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

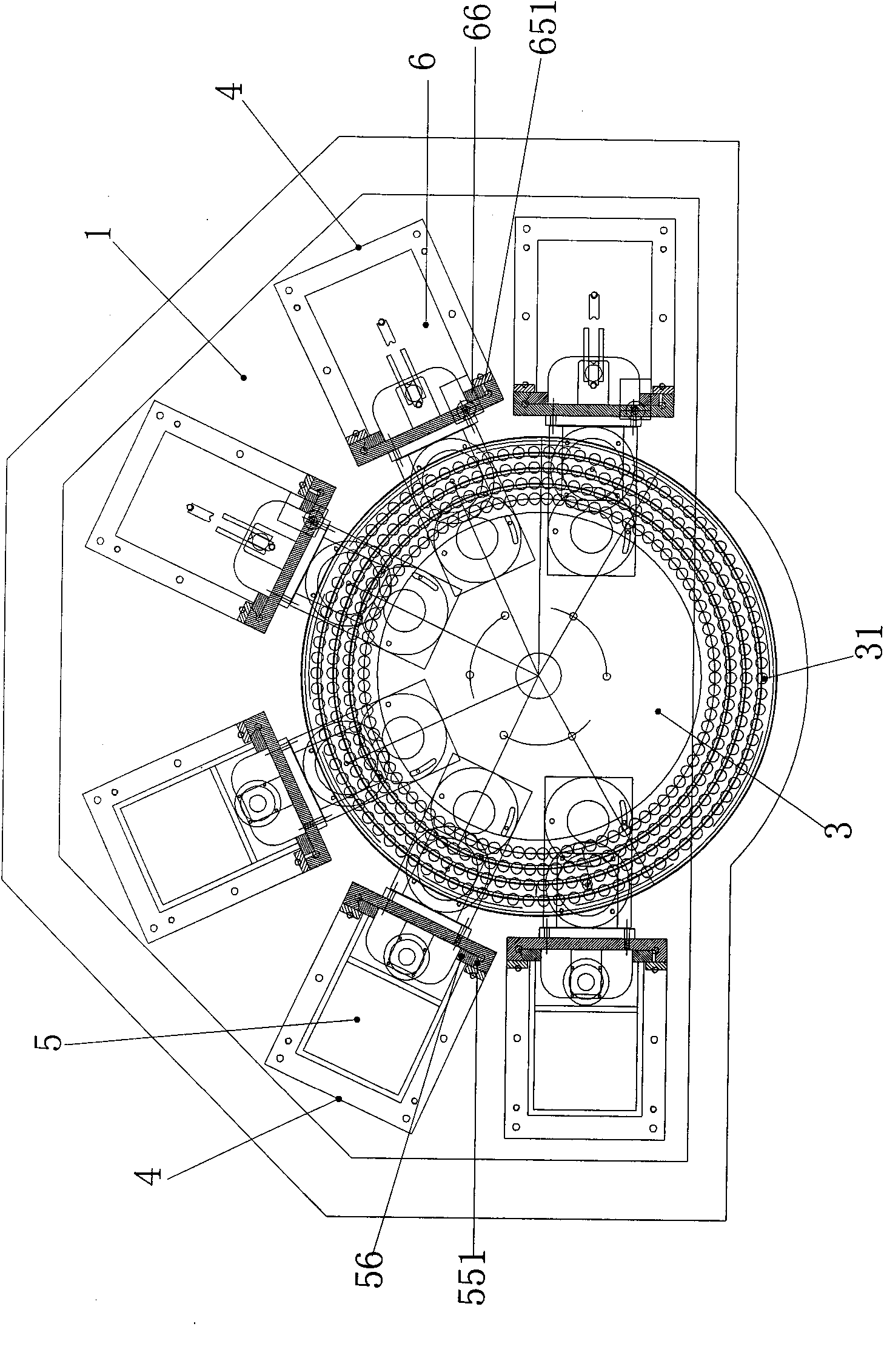

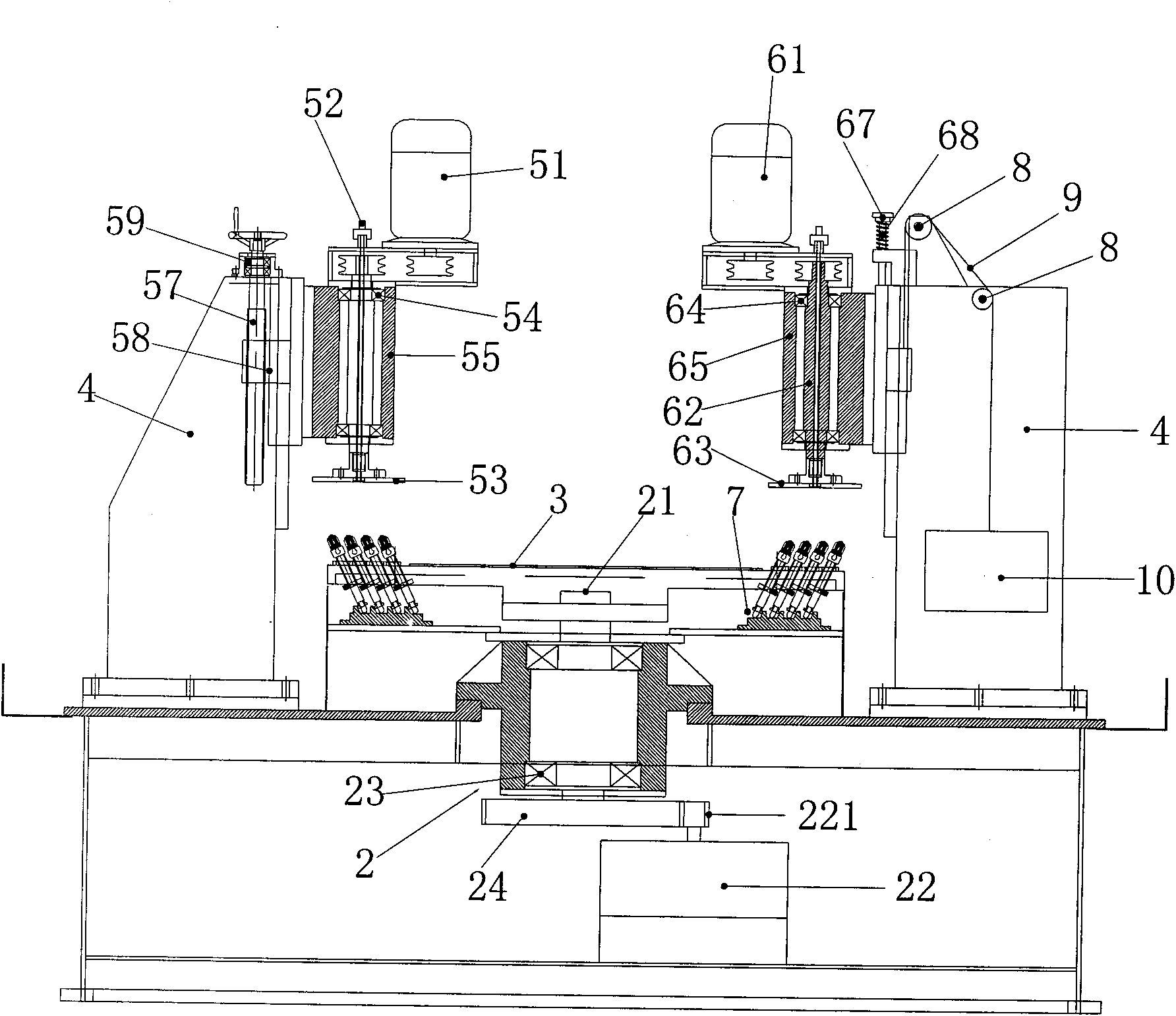

[0018] refer to figure 1 , figure 2 , a ring-shaped automatic grinding machine disclosed by the present invention includes a working platform 1, on which a fixture disk 3 is installed through a rotating mechanism 2, and the fixture disk 3 can move together with the rotating mechanism 2 when the rotating mechanism 2 operates A plurality of clamp holes 31 are annularly arranged on the clamp disk 3 , a clamp shaft 32 is installed in the clamp hole 31 , and a clamp 33 is installed at one end of the clamp shaft 32 .

[0019] As shown in the figure, six uprights 4 are arranged at intervals on the working platform 1, and the six uprights 4 are circumferentially distributed on the outside of the fixture disk 3, wherein each upright 4 is slidably mounted with a fine grinding device 5 or a polishing device 6, The fine grinding device 5 or the polishing device 6 is located above the jig 33 , and when the jig rotates to this station, the fine grinding device or the polishing device can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com