Method for shipping and unshipping sacked goods at wharf and ship loader and ship unloader

A technology of bagged articles and ship unloader, which is applied in the fields of ship unloader, ship unloading method and ship loading, and bagged article loading at the wharf. It can solve the problems of immobile cranes, low work efficiency, and high labor intensity, and achieve The effect of reducing the number of operators, easy manufacturing and implementation, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

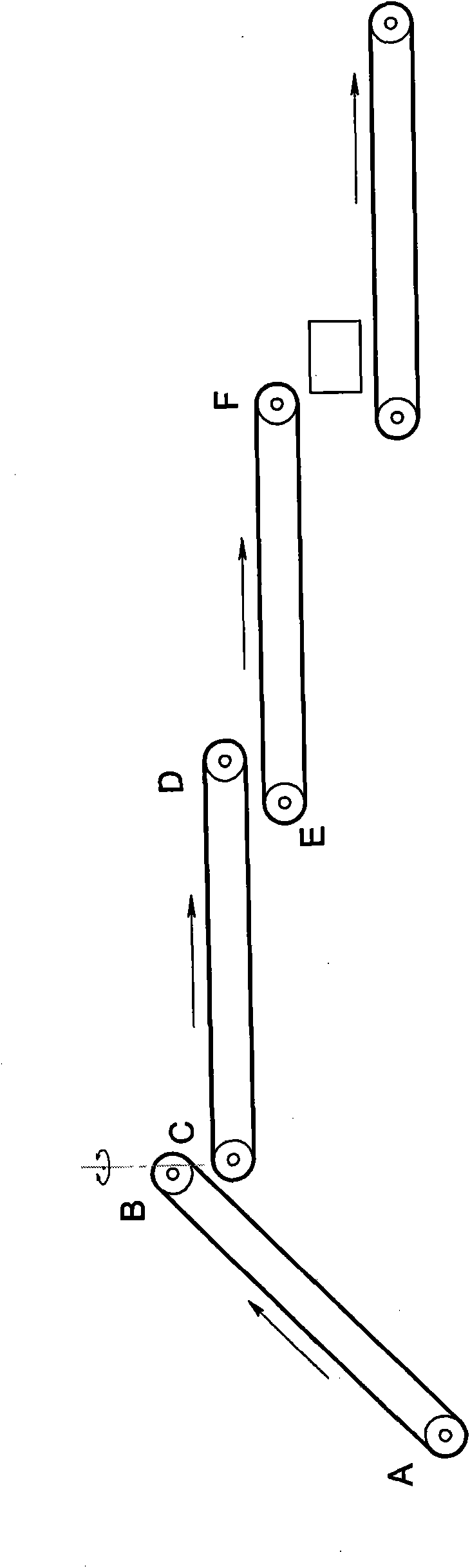

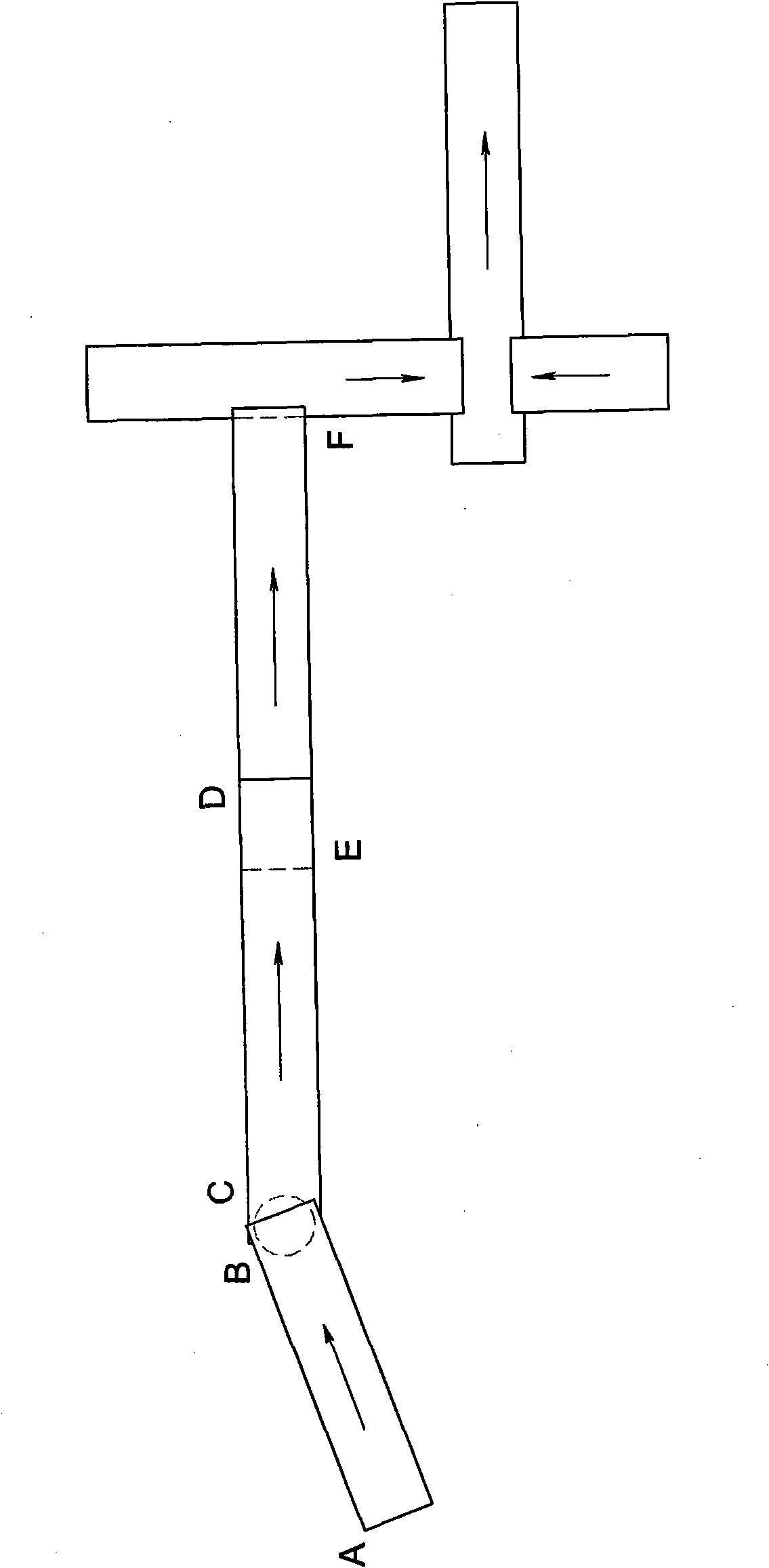

[0035] Embodiment one: see figure 1 , figure 2 , a method for unloading bagged goods at a wharf: a barge equipped with a ship unloader is driven between the cargo ship and the wharf, and the ship unloader is provided with an oblique transmission mechanism that can rotate along a horizontal axis and along a vertical axis at the same time, Wherein the horizontal axis and the vertical axis are all located at the upper part (or upper end) of the oblique transmission mechanism, according to the placement of the bagged articles in the cabin, adjust the delivery point A at the lower end of the oblique transmission mechanism near the bagged articles; The bagged items are placed at point A, and driven by the inclined conveyor, the bagged items are transported to the output point B at the upper end of the inclined conveyor; a telescopic horizontal conveying mechanism is set up behind and below point B, and the telescopic The horizontal conveying mechanism includes a fixed horizontal c...

Embodiment 2

[0037] Embodiment 2: The drawings are not drawn, and the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the oblique conveying mechanism can expand and contract along its conveying direction, so that the lower end conveying point of the oblique conveying mechanism The distance between A and the upper delivery point B can be adjusted.

Embodiment 3

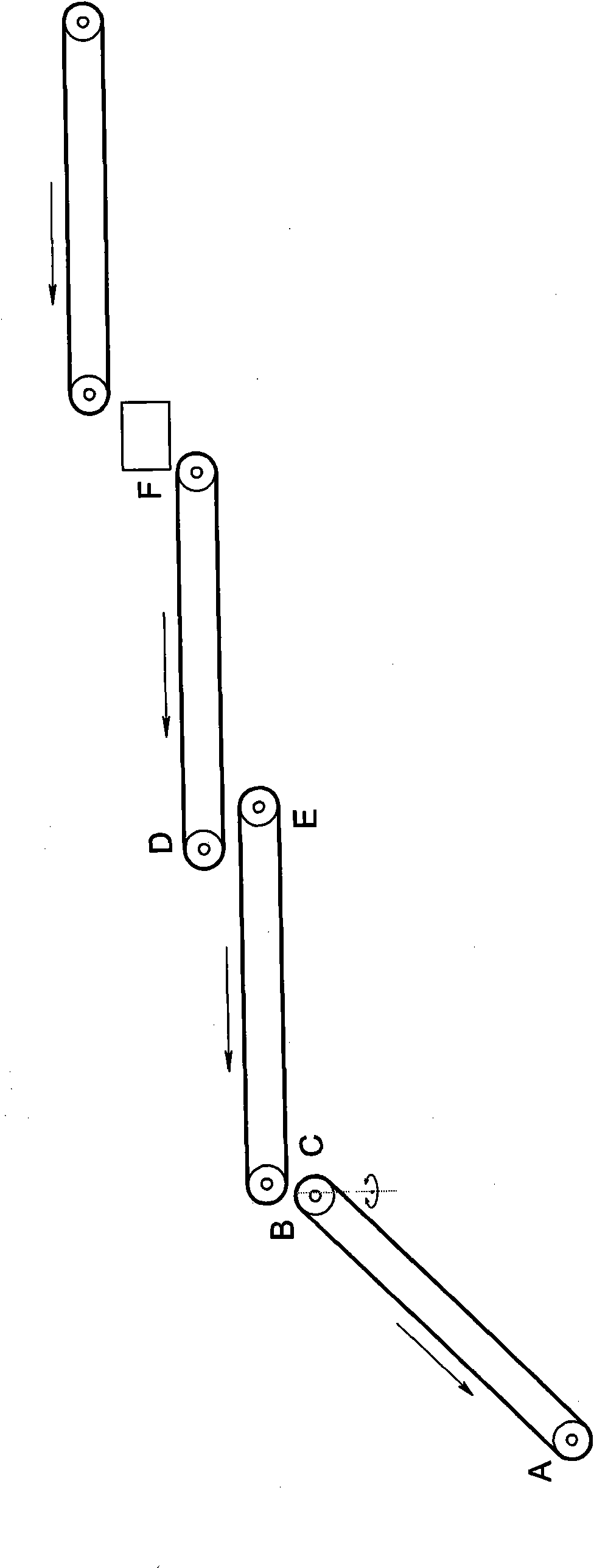

[0038] Embodiment three: see image 3 , Figure 4 , a method for loading bagged articles on a wharf, characterized in that a barge equipped with a ship loader is driven between the cargo ship and the wharf, and a horizontal belt conveyor connected to the wharf conveying mechanism is provided on the barge, A longitudinal belt conveyor is arranged at the front and lower part of the belt conveyor, and the bagged articles are transferred from the wharf conveying mechanism to the horizontal belt conveyor, and the horizontal belt conveyor then conveys the bagged articles to the longitudinal belt conveyor; before the longitudinal belt conveyor A horizontally telescopic horizontal conveying mechanism is provided below. The telescopic horizontal conveying mechanism includes a fixed horizontal conveyor belt and a telescopic horizontal conveyor belt. An oblique baffle is set in the middle section of the longitudinal belt conveyor so that the bagged items are forced to drop to The near-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com