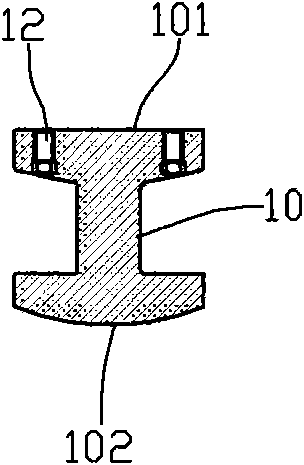

H-type prestressed concrete column and production method thereof

A technology of concrete columns and production methods, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of long construction period, poor fusion effect, and non-corrosion resistance, and achieve the effect of reducing construction costs, soft visual sense, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

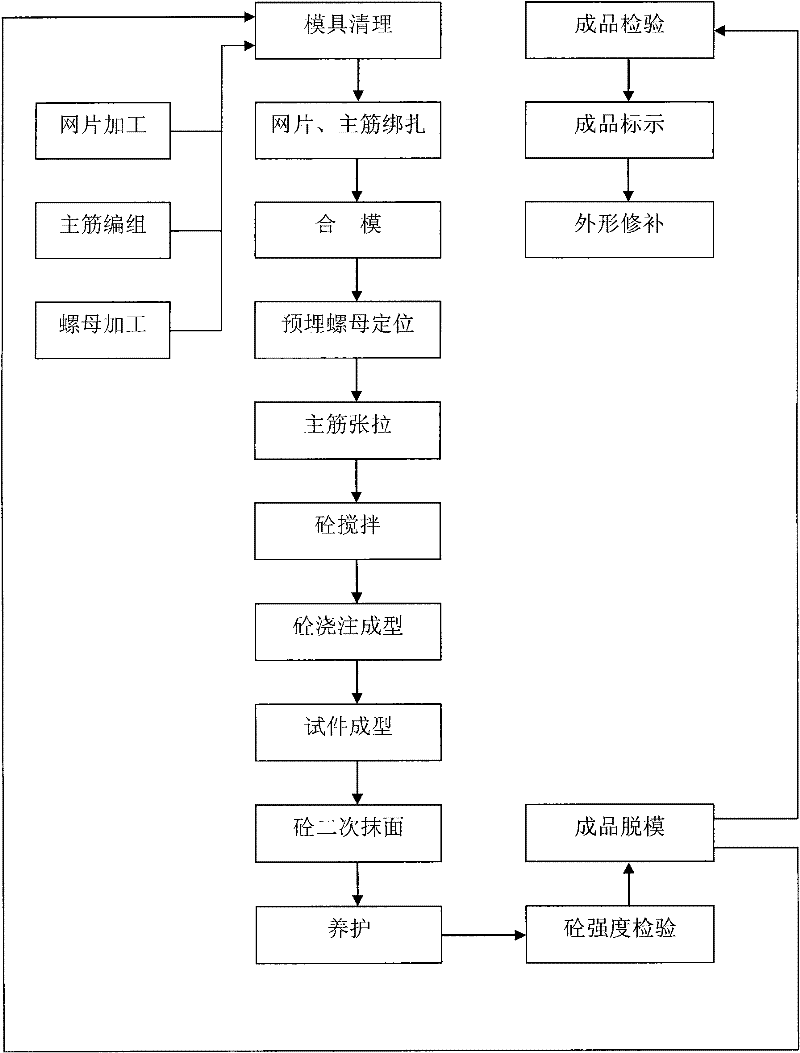

[0021] See figure 1 Shown: the production method of H type prestressed concrete column of the present invention comprises the steps: (1) batching, take ordinary portland cement as cementing material, and infiltrate a certain proportion of sand, stone, water, and as admixture The weight ratio of fly ash, slag powder, water reducing agent, anti-cracking fiber, cement, sand, stone, water, and admixture is 1:1.21:2.35:0.31:0.015; (2) Prepare embedded parts, carry out Mesh processing, main reinforcement (reinforcement) grouping, and nut processing; (3) mold cleaning; (4) mesh and main reinforcement binding; (5) mold closing; (6) pre-embedded nut positioning; (7) main reinforcement tensioning; (8) Concrete mixing; (9) Concrete pouring and molding; (10) Test piece forming; (11) Concrete secondary plastering; (12) Curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com