Disc brake apparatus

A disc brake and equipment technology, applied in the direction of mechanical equipment, brake type, axial brake, etc., can solve the problems of uneven wear of the liner, insufficient surface pressure distribution, etc., to reduce processing costs, stable performance, Effect of suppressing brake noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

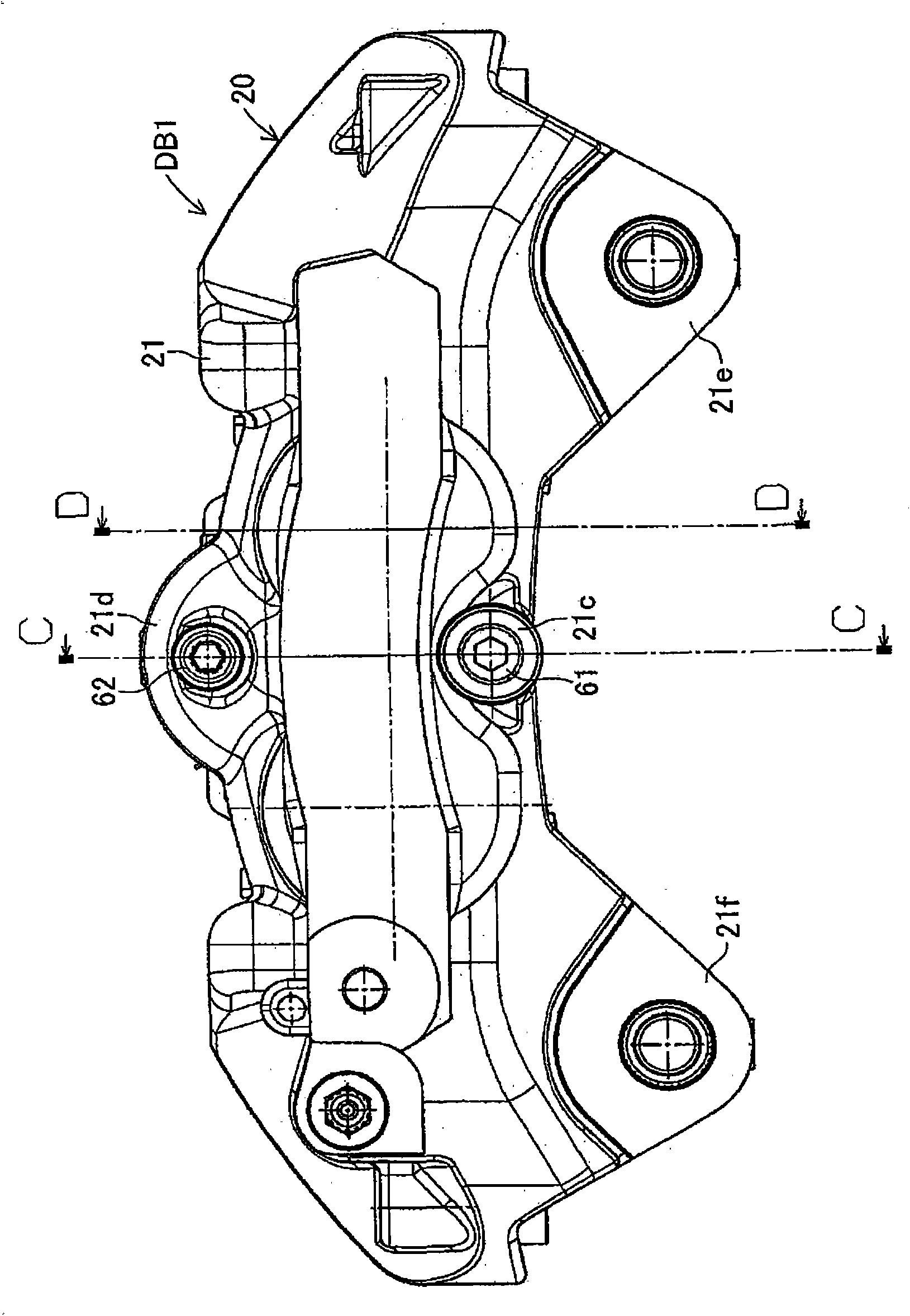

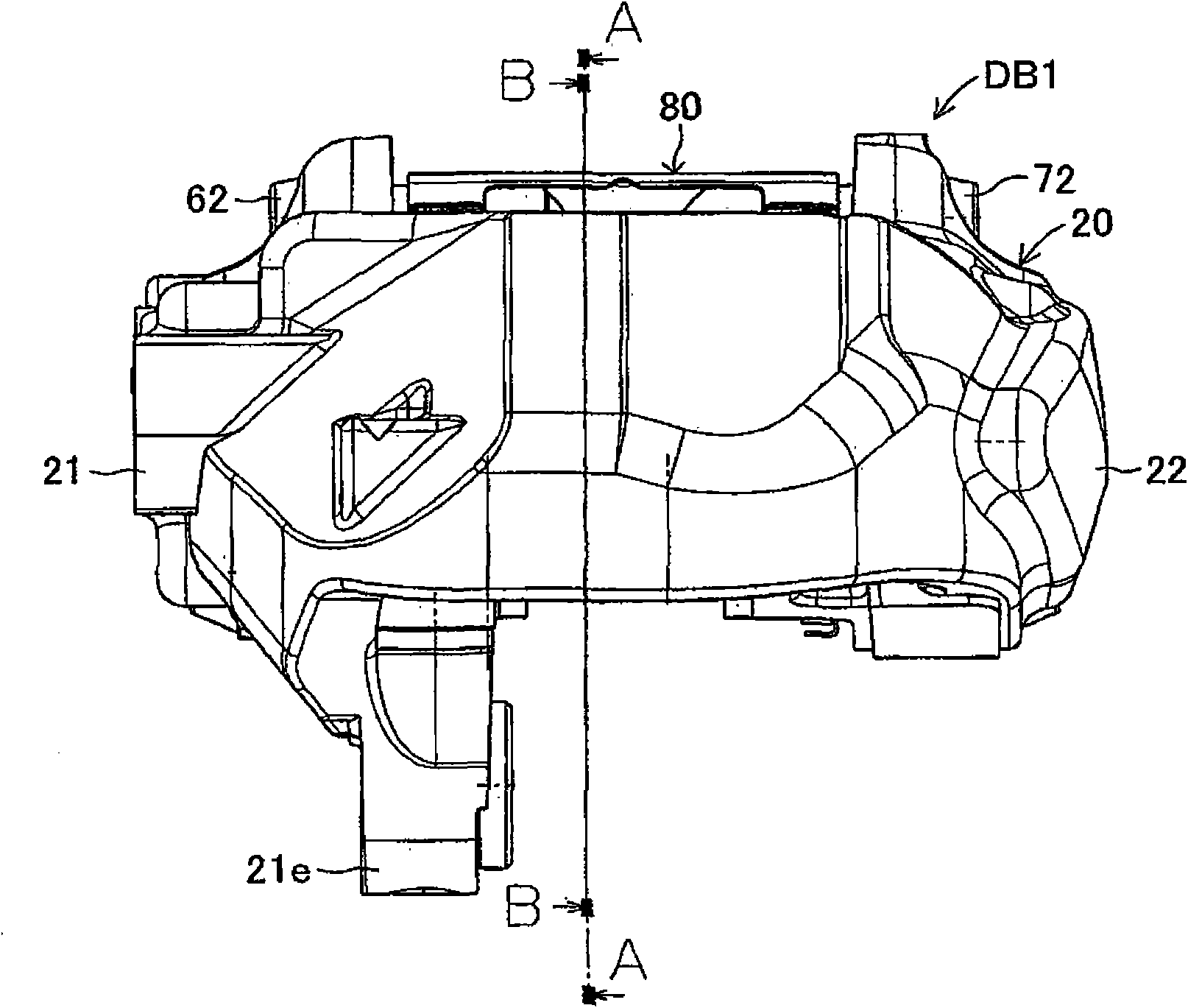

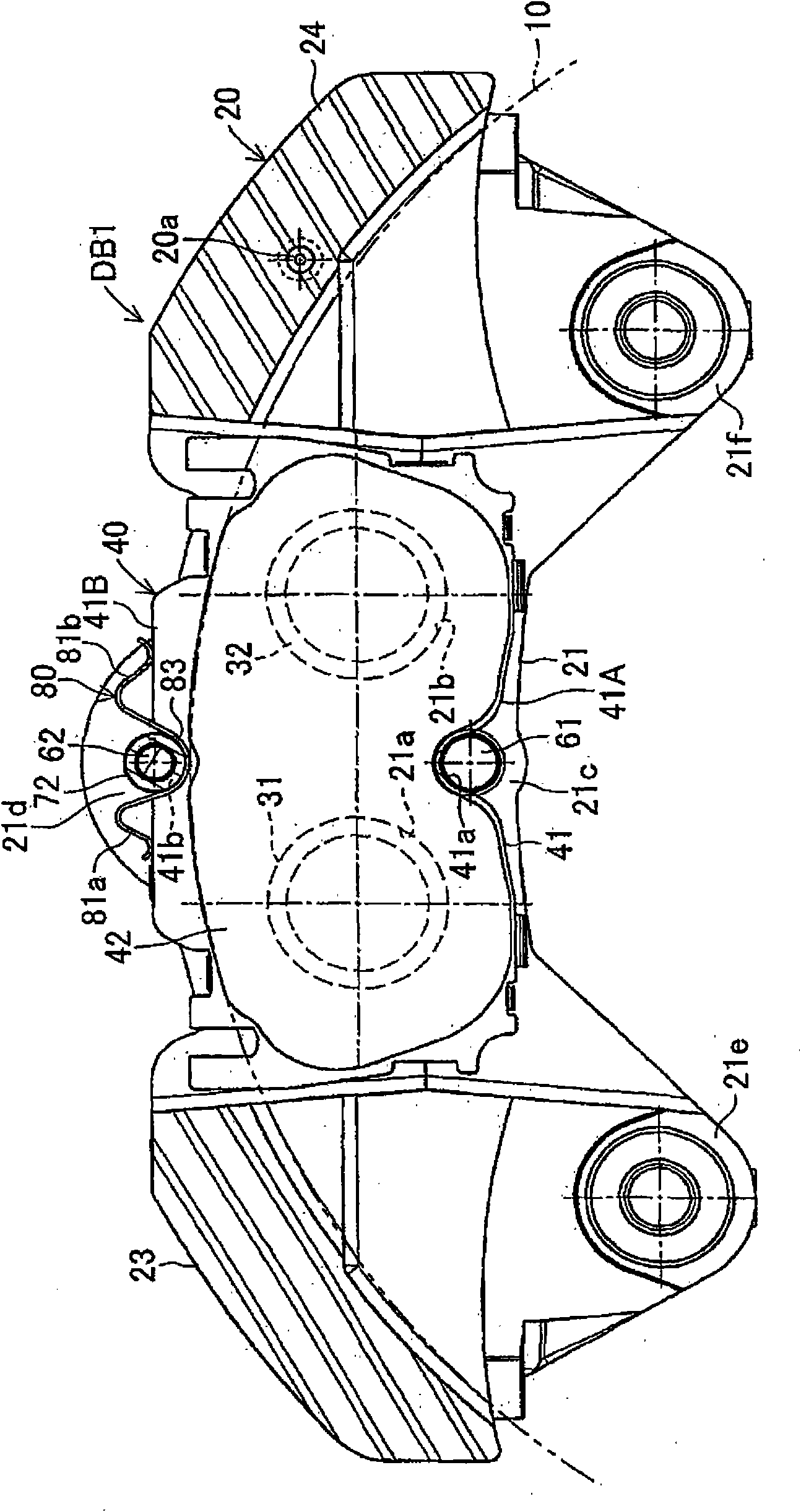

[0023] Figure 1 to Figure 6 A first embodiment is shown in which the disc brake device of the present invention is used as an opposed-piston type (fixed type) disc brake device for a vehicle. The disc brake apparatus DB1 according to the first embodiment is provided with a disc rotor 10 connected to a hub (rotation member not shown in the figure) and integrally with a wheel (not shown) Rotation; brake caliper 20, which is arranged to straddle a part of the outer circumference of the disc rotor 10; four pistons 31, 32, 33, 34 connected to the brake caliper 20; inner brake pads 40; and the outer brake pad 50. The disc brake apparatus DB1 is also provided with an inner inner peripheral support shaft 61 , an inner outer peripheral support shaft 62 , an outer inner peripheral support shaft 71 , an outer outer peripheral support shaft 72 , and a leaf spring 80 in the caliper 20 .

[0024] Such as Figure 5 As shown, the disc rotor 10 has circular braking surfaces 10 a , 10 b cla...

no. 2 approach

[0046] Figure 7 to Figure 10A second embodiment is shown in which the disc brake device of the present invention is used as an opposed-piston type (fixed type) disc brake device for a vehicle. The disc brake apparatus DB2 according to the second embodiment is provided with a disc rotor 110 connected to a hub (rotation member not shown in the figure) and integrally with a wheel (not shown) rotation; brake caliper 120, which is arranged to straddle a portion of the outer circumference of the disc rotor 110; four pistons 131, 132, 133, 134 connected to the brake caliper 120; inner brake pads 140; and the outer brake pad 150. The disc brake apparatus DB2 is also provided with an inner inner peripheral support shaft 161 , a pair of inner outer peripheral support shafts 162 , 162 , an outer inner peripheral support shaft 171 , a pair of outer outer peripheral support shafts 172 , 172 , and a leaf spring 180 .

[0047] According to the second embodiment, a pair of inner peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com