Back light module

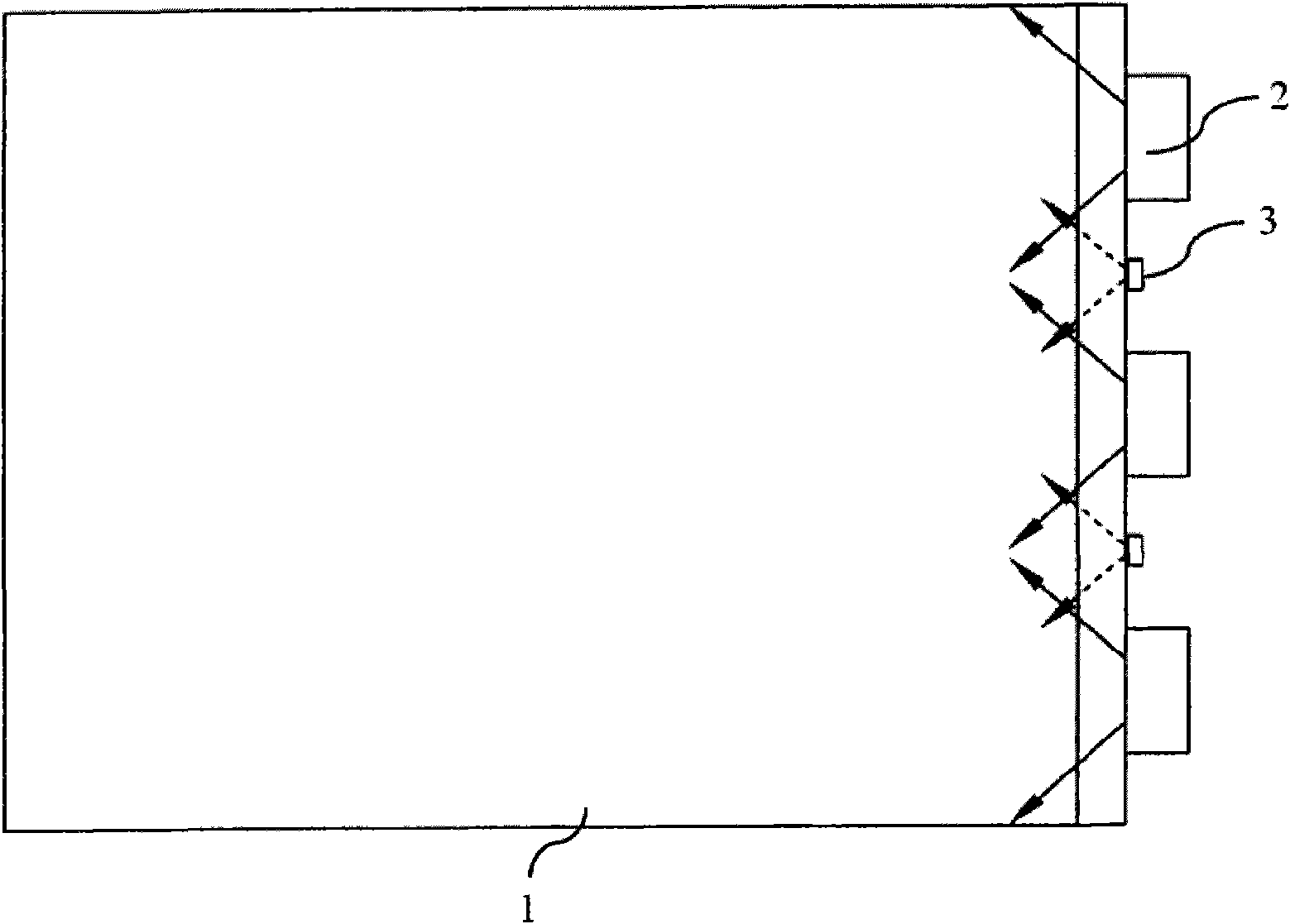

A backlight module and light source technology, which is applied in the field of side-illuminated backlight, can solve the problems of bright and dark areas, difficult heat source dissipation, and difficult manufacturing process, and achieve the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

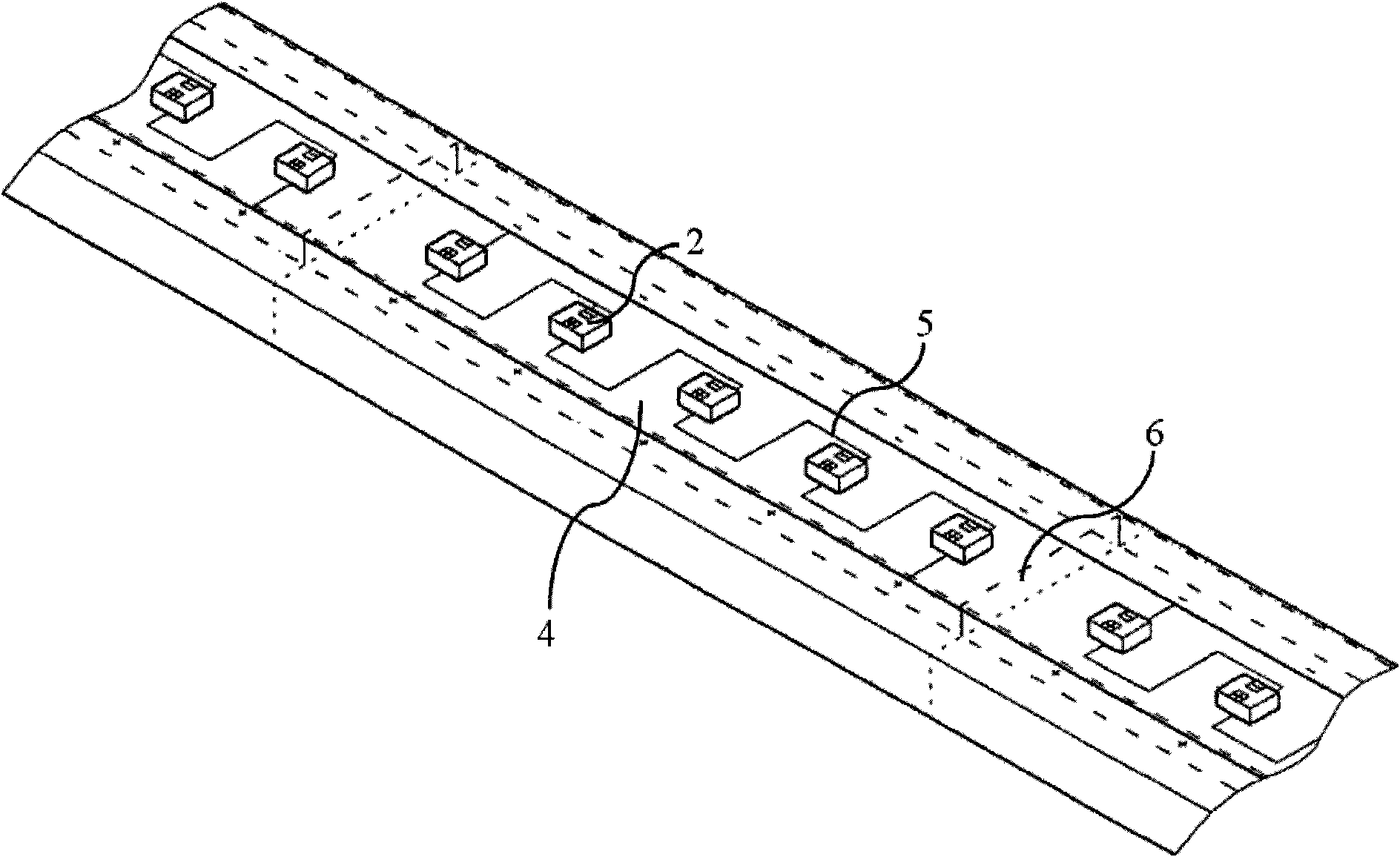

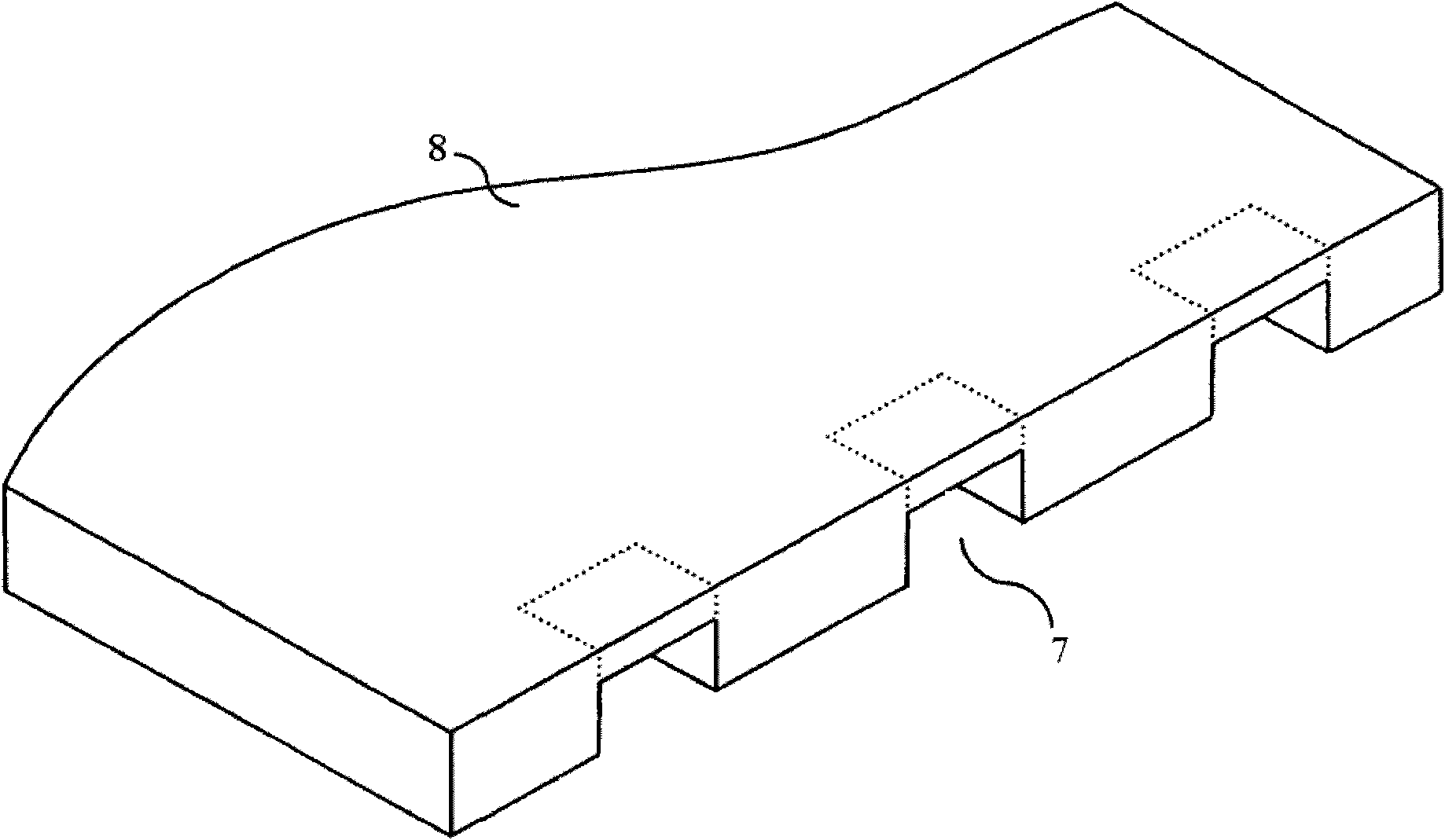

[0103] Herein, the present invention provides a second embodiment, changing the distribution of microstructures inside the light guide plate 8 to improve the reflection efficiency of the plurality of reflective sheets 11 . Please refer to Figure 7 In the top view of the light guide plate 8 provided by the present invention, the microstructures inside the light guide plate 8 include general density microstructures 21 and multiple high-density microstructures 20, especially the above-mentioned multiple high-density microstructures 20 are adjacent to the light incident surface 81. In addition, the distribution area of the above-mentioned multiple high-density microstructures 20 is the dark band area 17 projected by the separated light source 10 on the light guide plate 8 (drawn in Figure 5 ). In summary, the light source in the dark zone is increased through the second elongated reflector 14, and the light beam reflectivity in the dark zone is increased through the distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com