Tubular column type instrument board framework visual detection positioning device of automobile

A technology for visual detection and positioning devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that no one has proposed automatic positioning equipment, etc., and achieve the effect of simple structure, easy operation, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

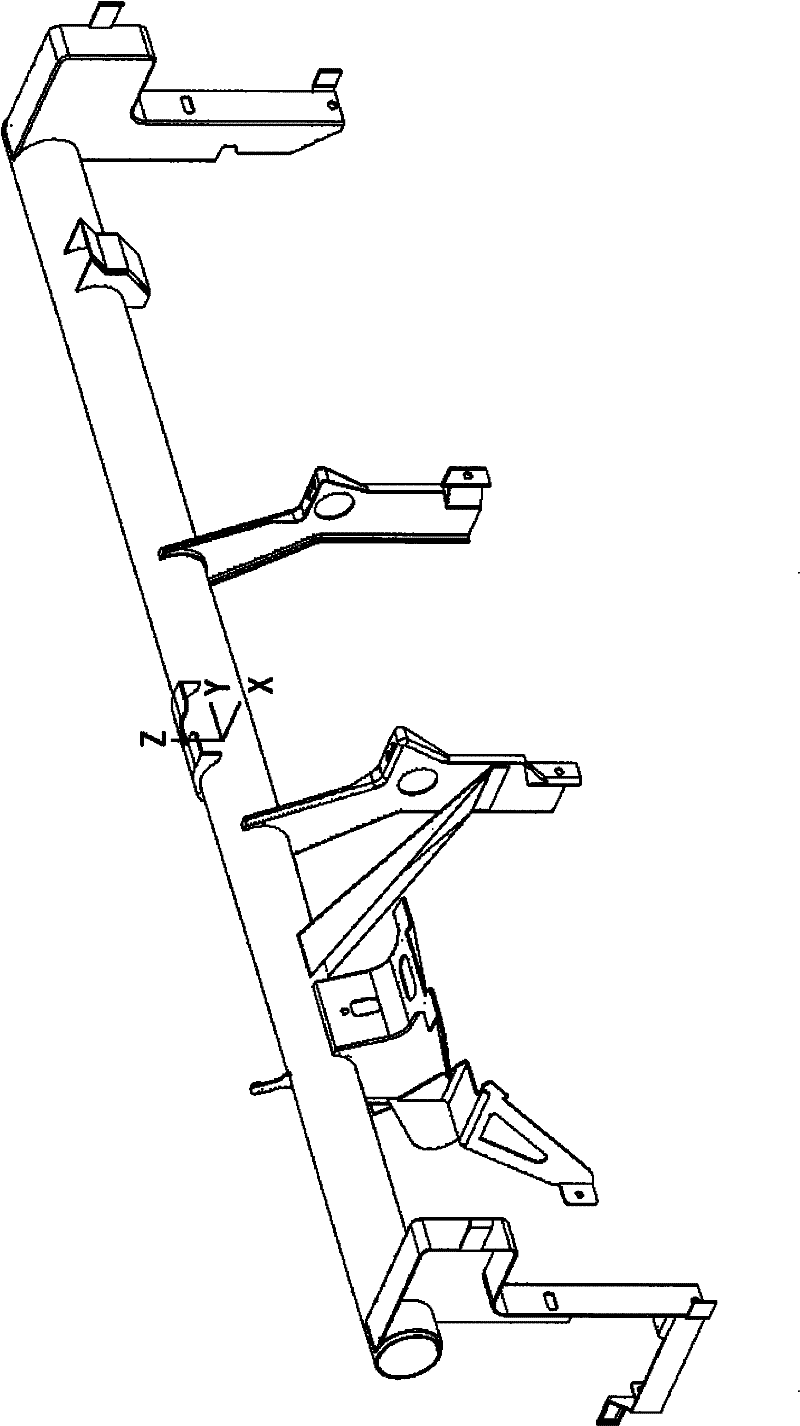

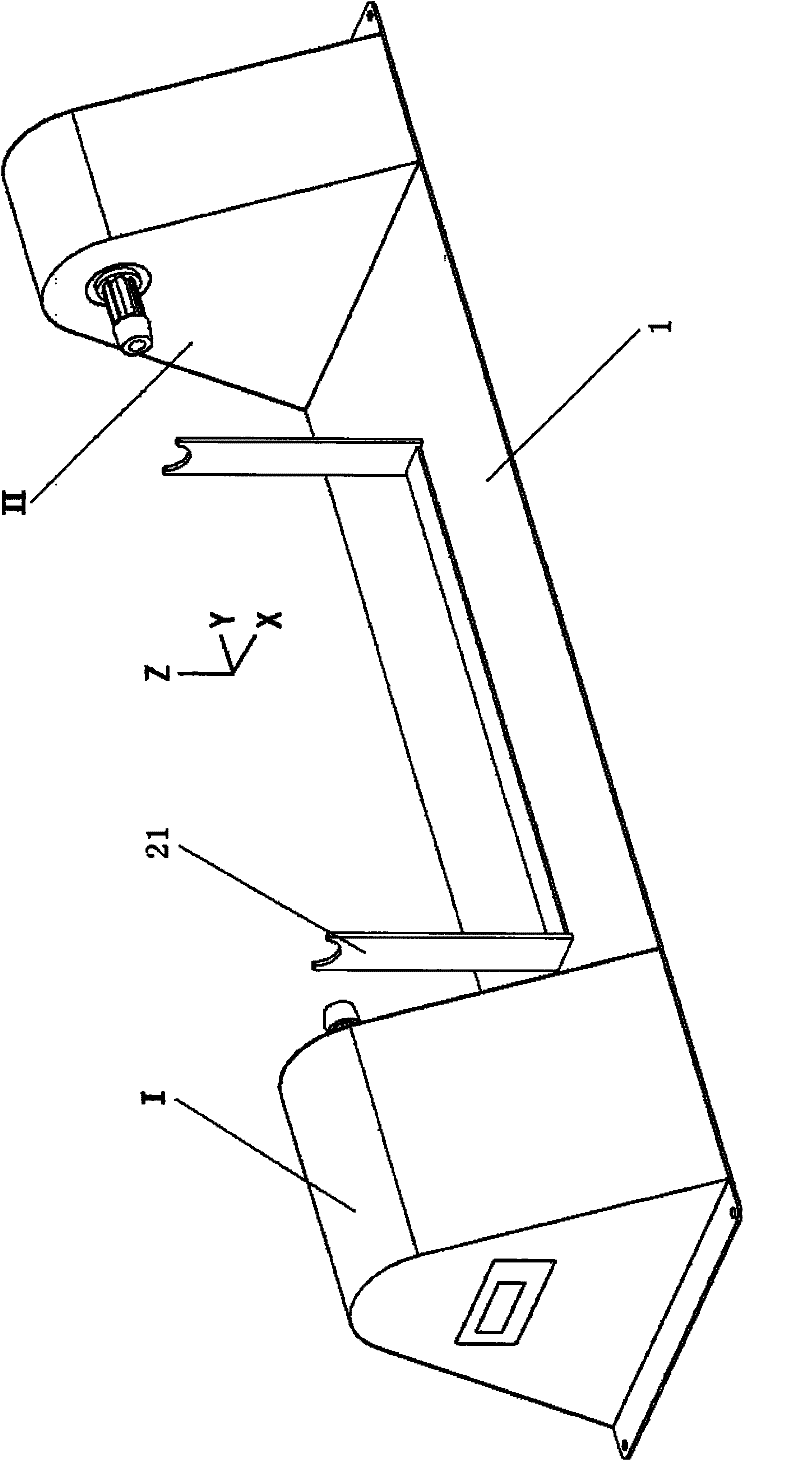

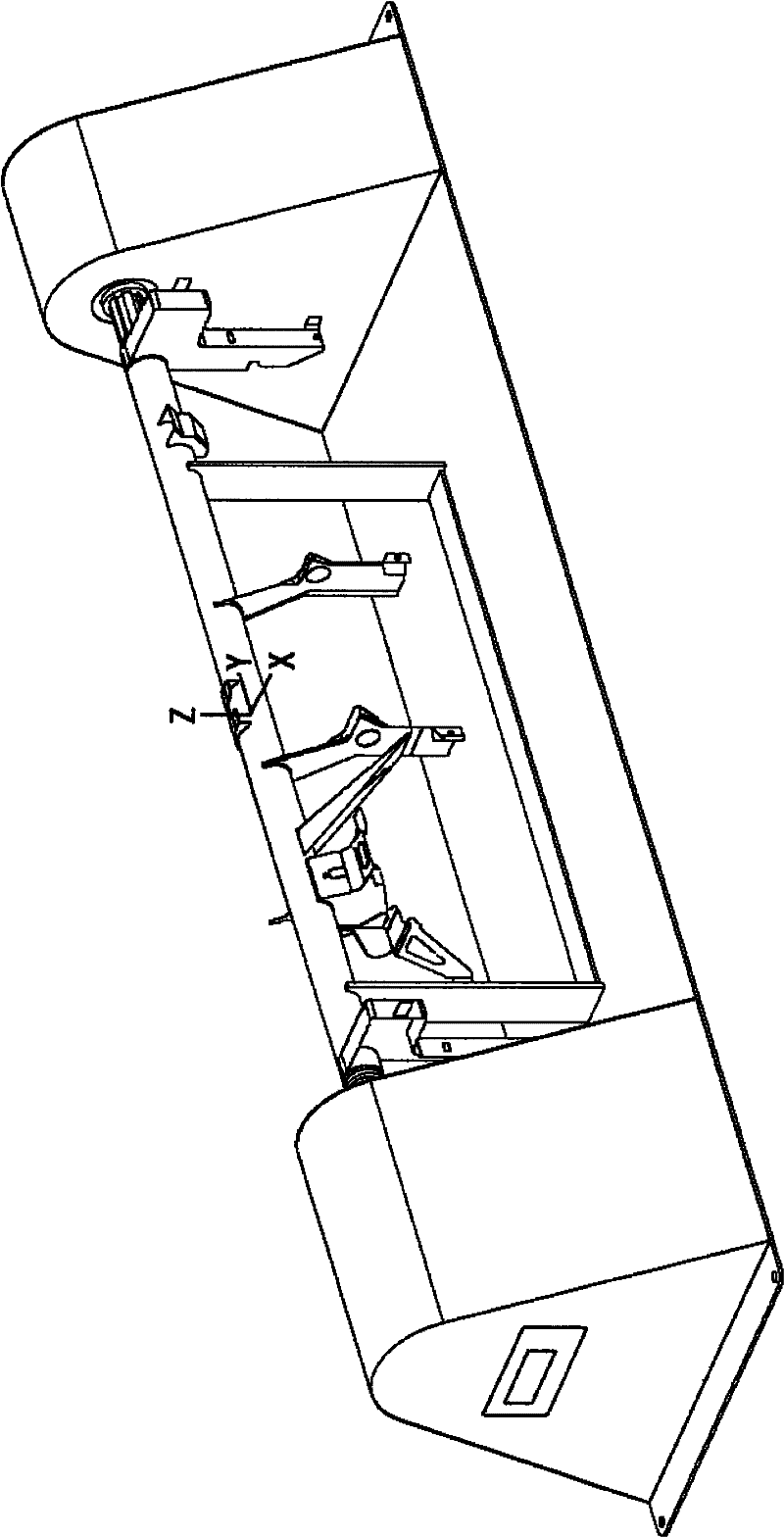

[0027] refer to figure 2 According to the present invention, the visual detection and positioning device for the framework of an automobile column instrument panel is composed of a base plate 1, a U-shaped support seat 21, a driving part I and a driven part II. The U-shaped supporting base 21 is fixed in the middle of the base plate 1 along the direction of the Y axis, and the driving part I and the driven part II are respectively fixed on the base plate 1 on the left and right sides of the U-shaped supporting base 21 .

[0028] The base plate 1 is a structural member of the plate type, and is made of a casting method or a steel plate. In the embodiment of the present invention, a flat steel plate with a thickness of 5mm is used. The base plate 1 is fixed on the foundation with evenly distributed bolts around it.

[0029] The U-shaped support seat 21 is a U-shaped structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com