Quickly ration loading system

A fast, train technology, applied in loading/unloading, transportation and packaging, program control in sequence/logic controllers, etc., can solve the problem of inability to automatically identify various types of carriages, inability to automatically batch and mix loading, loading and unloading. The system can not meet the needs and other problems, to achieve the effect of saving manpower, powerful functions, and improving safety performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained and described in the following non-limiting embodiments.

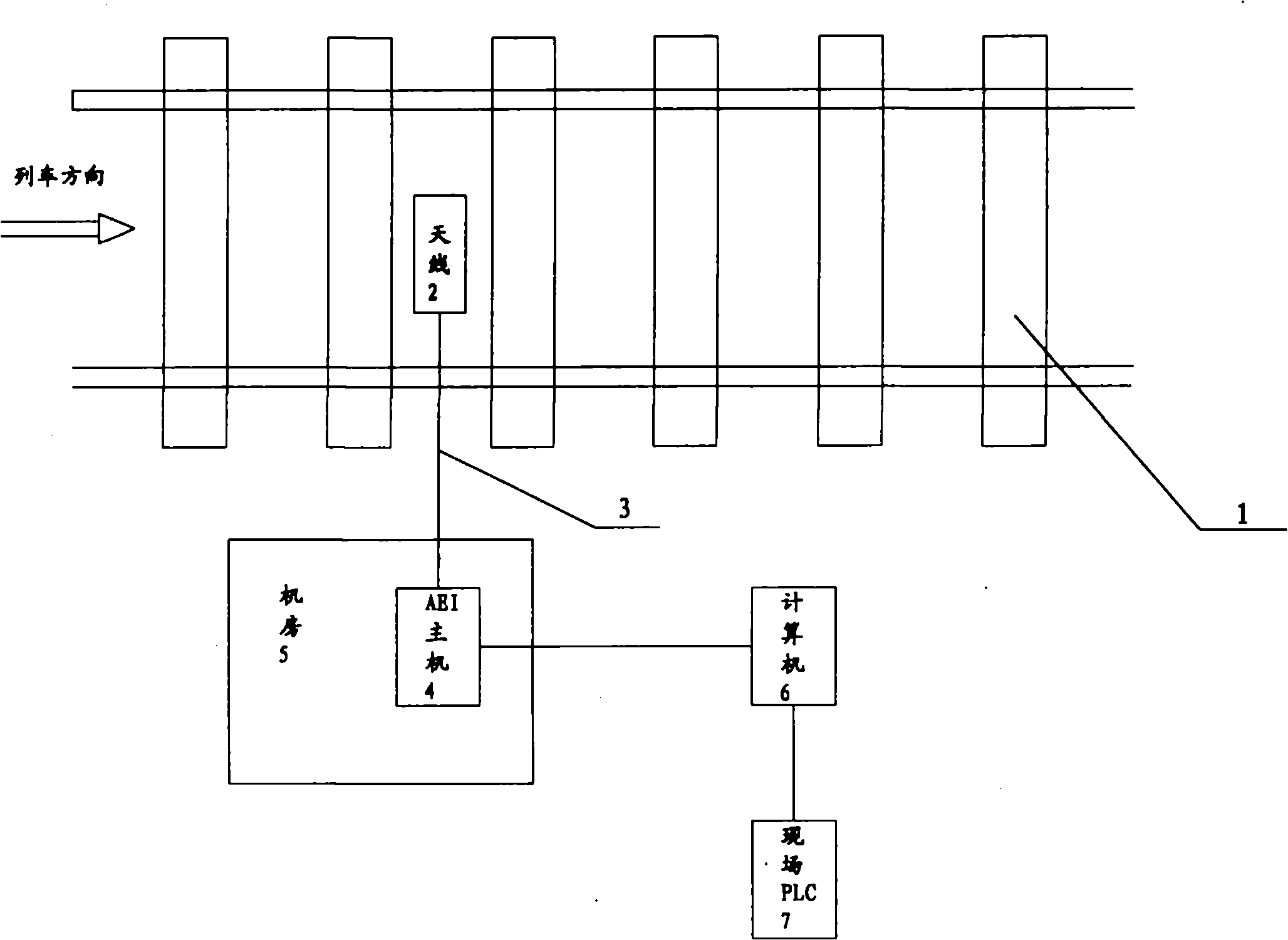

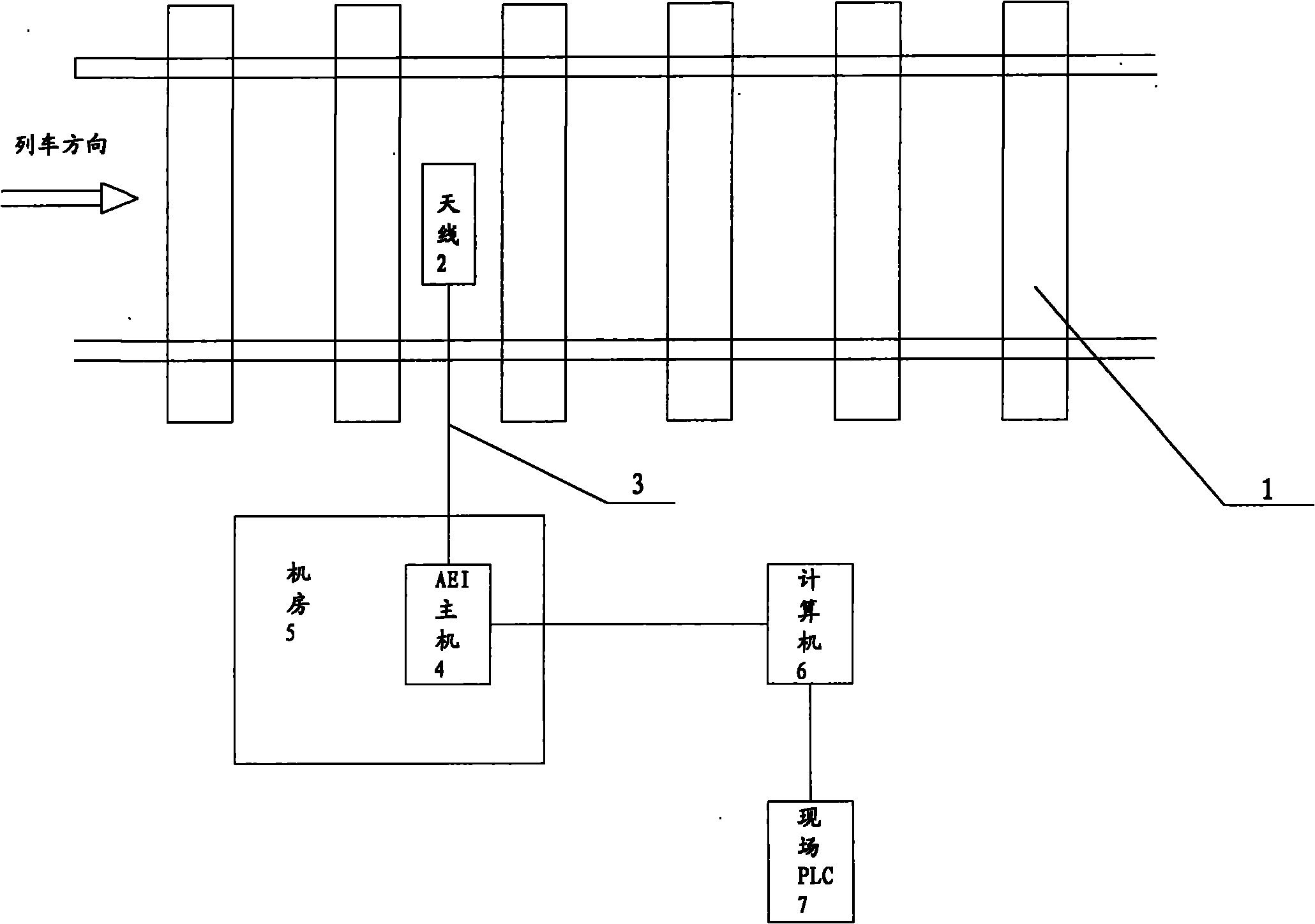

[0023] A rapid quantitative loading system, such as figure 1 The structure shown is used in the field of train loading. An electronic tag is fixed at the bottom of the train, and the data information of the train is recorded in the electronic tag, including the car number, the rated gross weight of the car, tare weight, rated loading weight, and actual loading. Weight, remarks, etc., are easy to implement and will not be described in detail.

[0024] An antenna 2 that can read the above-mentioned electronic tags is provided on the rail 1, and the data information in the electronic tags is collected by the antenna, and sent to the readout device connected to it through the signal transmission antenna 3-the AEI host 4, and the AEI host 4 is generally set In the machine room 5 near the railway, it is necessary to be safe and anti-theft, ventilated and waterproof. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com