Fabricating methods for special power electronic circuit board for power supply and power module

A technology for power electronics and power modules, which is applied to the production of power electronic circuit boards and power modules for power supplies, can solve problems such as low integration, inconvenient design, and thick sealant, and achieve the effect of overcoming small capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1. Make A type, B type, E type special-purpose power electronic circuit board with A type, B type, E type general power electronic circuit board substrate

[0044] The method of making A-type, B-type, E-type special-purpose power electronic circuit boards with A-type, B-type, E-type general power electronic circuit board substrates is as follows:

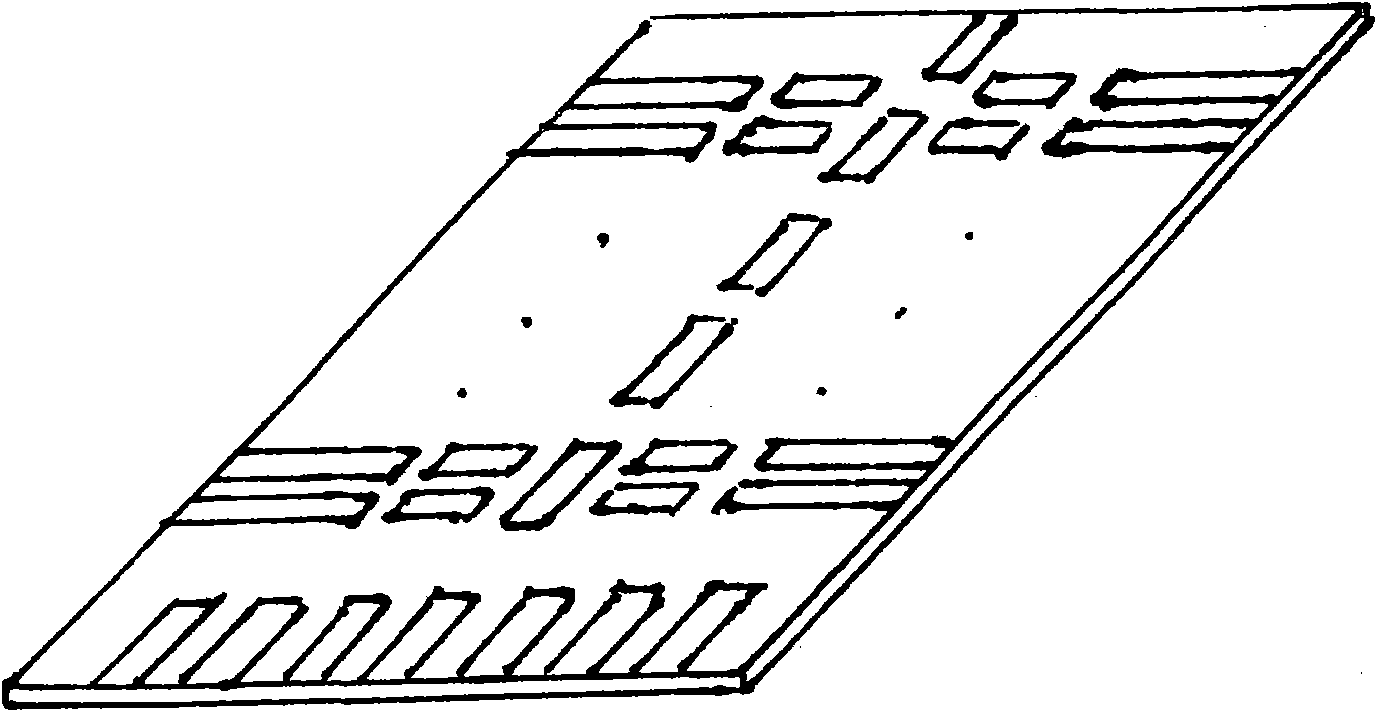

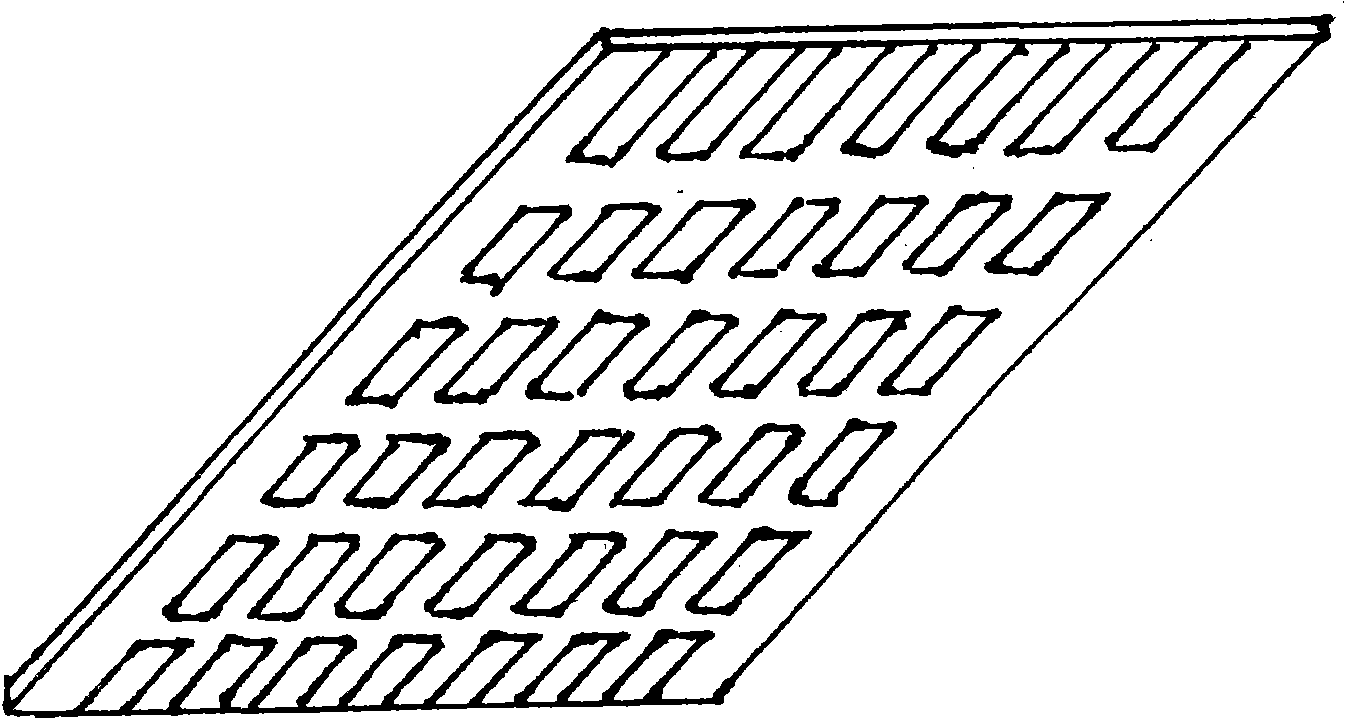

[0045] 1. Draw the arrangement and wiring diagram of various power module components, determine the arrangement and wiring diagram of general components and the copper mooring distribution diagram on the front and back of the general power electronic circuit board substrate of type A, type B and type E, and outsource customizing type A and B Type and E-type general-purpose power electronic circuit board substrates. The general-purpose holes on the substrate are holes with a diameter of 1 mm. Such as Figure 1a , Figure 1b , Figure 3a , Figure 3b , Figure 4a with Figure 4b ;

[0046] 2. Make power copper ...

Embodiment 2

[0056] Embodiment 2. Make C type, D type, F type special-purpose power electronic circuit board with C type, D type, F type general power electronic circuit board substrate

[0057] The method of making C-type, D-type, and F-type special-purpose power electronic circuit boards with C-type, D-type, and F-type general-purpose power electronic circuit board substrates is as follows:

[0058] 1. Draw C-type, D-type, F-type general power electronic circuit board substrate structure diagrams, and outsource custom C-type, D-type, F-type substrates, such as Figure 2a , Figure 2b , Figure 2c , Figure 2d , Figure 5a with Figure 5b ;

[0059] 2. Steps 2, 3, 4, and 5 are the same as in Example 1.

Embodiment 3

[0060] Embodiment 3. adopt D type, F type universal power electronic circuit board substrate to make D type, F type special power electronic circuit board with casting method

[0061] The method of making D-type and F-type special-purpose power electronic circuit boards by casting method is as follows:

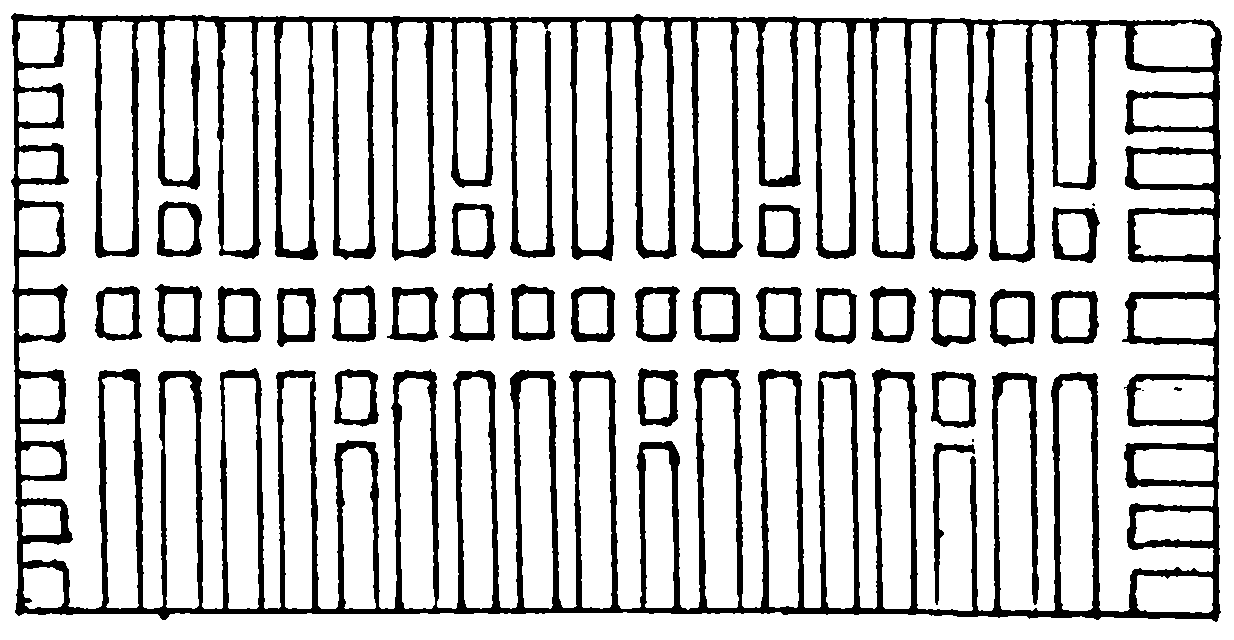

[0062] 1. Draw the structure diagram of D-type and F-type substrates, casting boxes, copper wire slot filler blocks with power, and wireless slot filler blocks, and outsource customized D-type and F-type substrates, casting boxes, copper wire slot filler blocks with power, and wireless slot filler blocks. Slot filler blocks such as Figure 12a , Figure 12b , Figure 12c , Figure 12d ;

[0063] 2. Put the D-type or F-type substrate face up into the casting box;

[0064] 3. Put the filler block with power copper wire groove into the casting box with the wire groove facing down and make the wire groove of the filler block coincide with the extension line of the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com