Preparation method of carbon nano tube array for spinning

A carbon nanotube array and spinning technology, which is applied in the field of preparation of large-area spinnable carbon nanotube arrays, can solve the problems of no breakthrough in large-area preparation technology and the failure to realize carbon nanotube array film drawing technology, and achieve Ease of understanding, high carbon tube surface distribution density, and the effect of a small number of tube walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

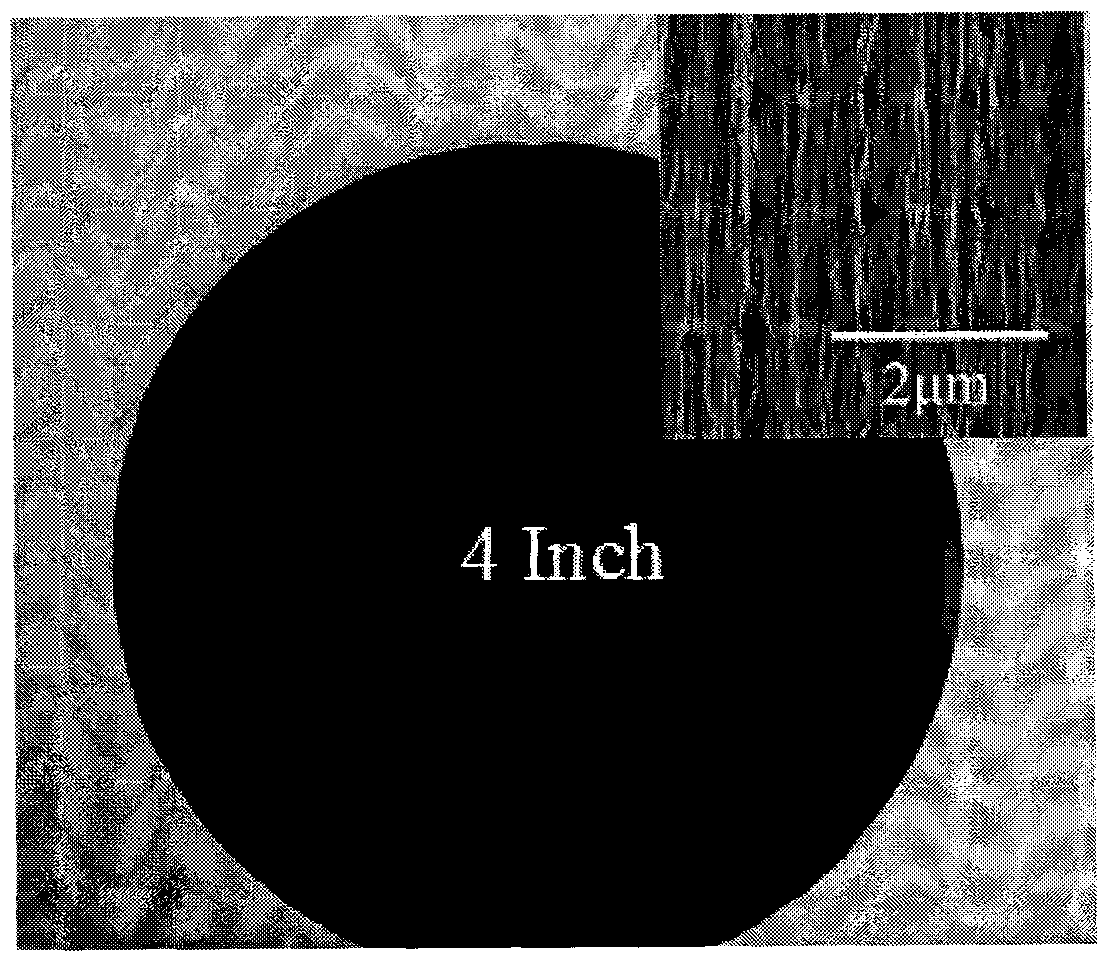

[0029]In view of the wall number, tube diameter, defect density and physical and chemical properties of carbon nanotubes grown by ethylene CVD are different from those of acetylene CVD, its application prospect is broad. In order to break through the bottleneck of preparing large-area spinnable carbon nanotube arrays by the ethylene CVD method, the inventive team of the present invention has finally developed the preparation method of the nanotube array for spinning after painstaking research. The preparation method has good repeatability. And it is easy to scale up and implement; the resulting large-area spinnable carbon nanotube array can be used to prepare new materials such as transparent conductive films and high-performance carbon nanotube fibers.

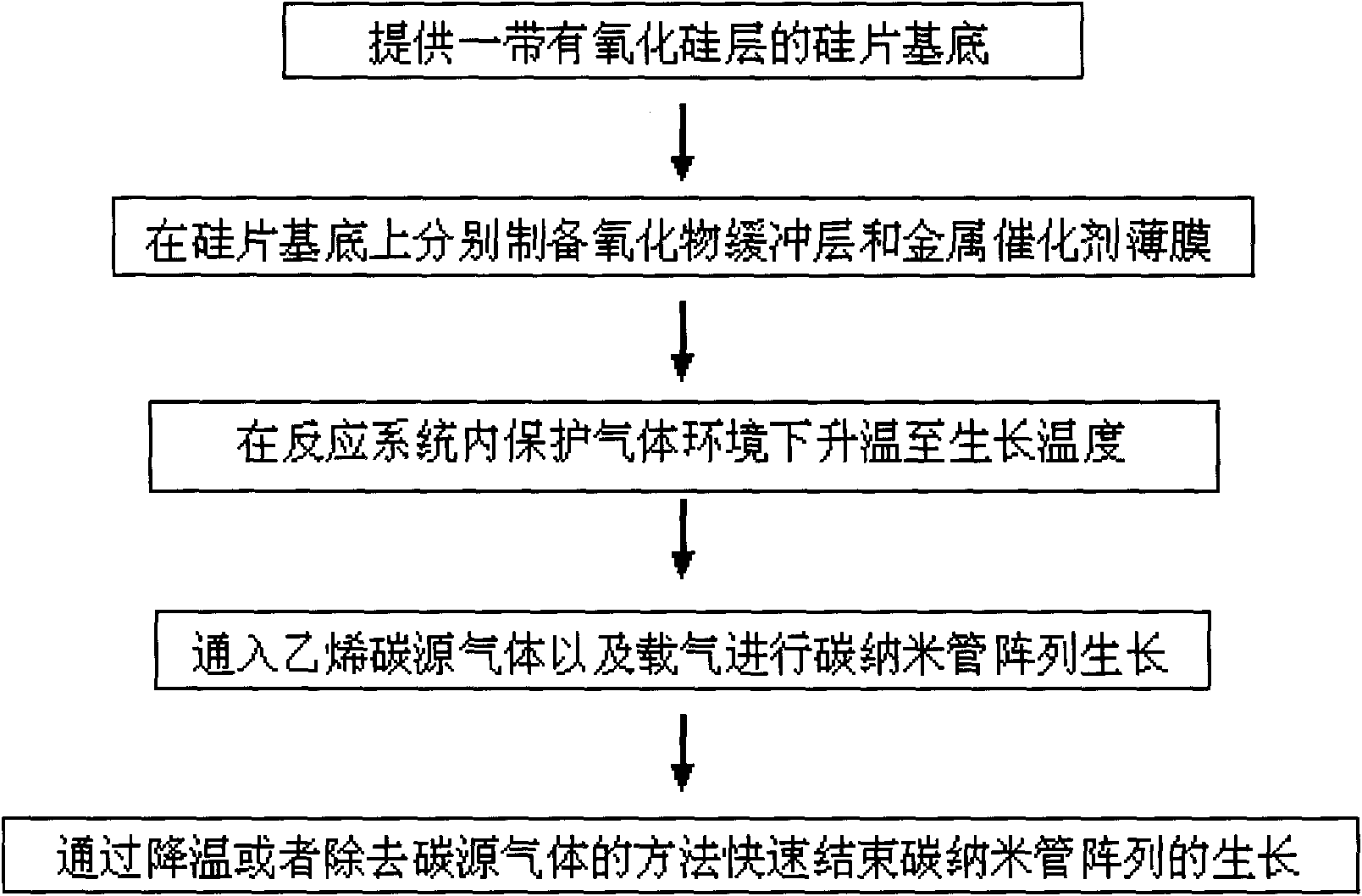

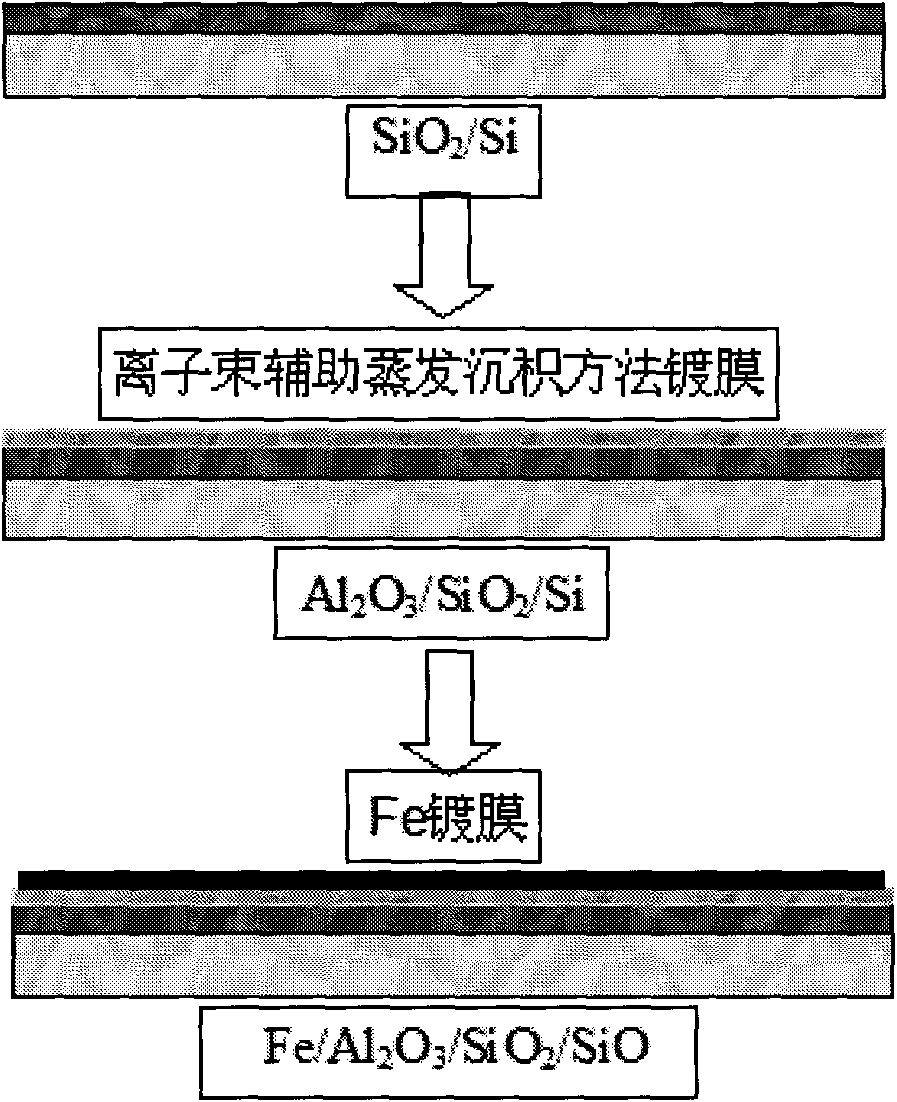

[0030] Specifically: the realization steps of the preparation method of the present invention are as follows: figure 1 As shown in the schematic diagram of the flow chart, it mainly includes four steps, which are: first prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com