Automatic-feeding type marl bucket

An automatic feeding and plaster technology, which is applied in the field of automatic feeding plaster buckets and automatic feeding plaster buckets, can solve the problems of low production efficiency, unsuitability of powdery materials, and high labor intensity of workers. Achieve the effect of convenient and flexible use, cheap price and strong practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

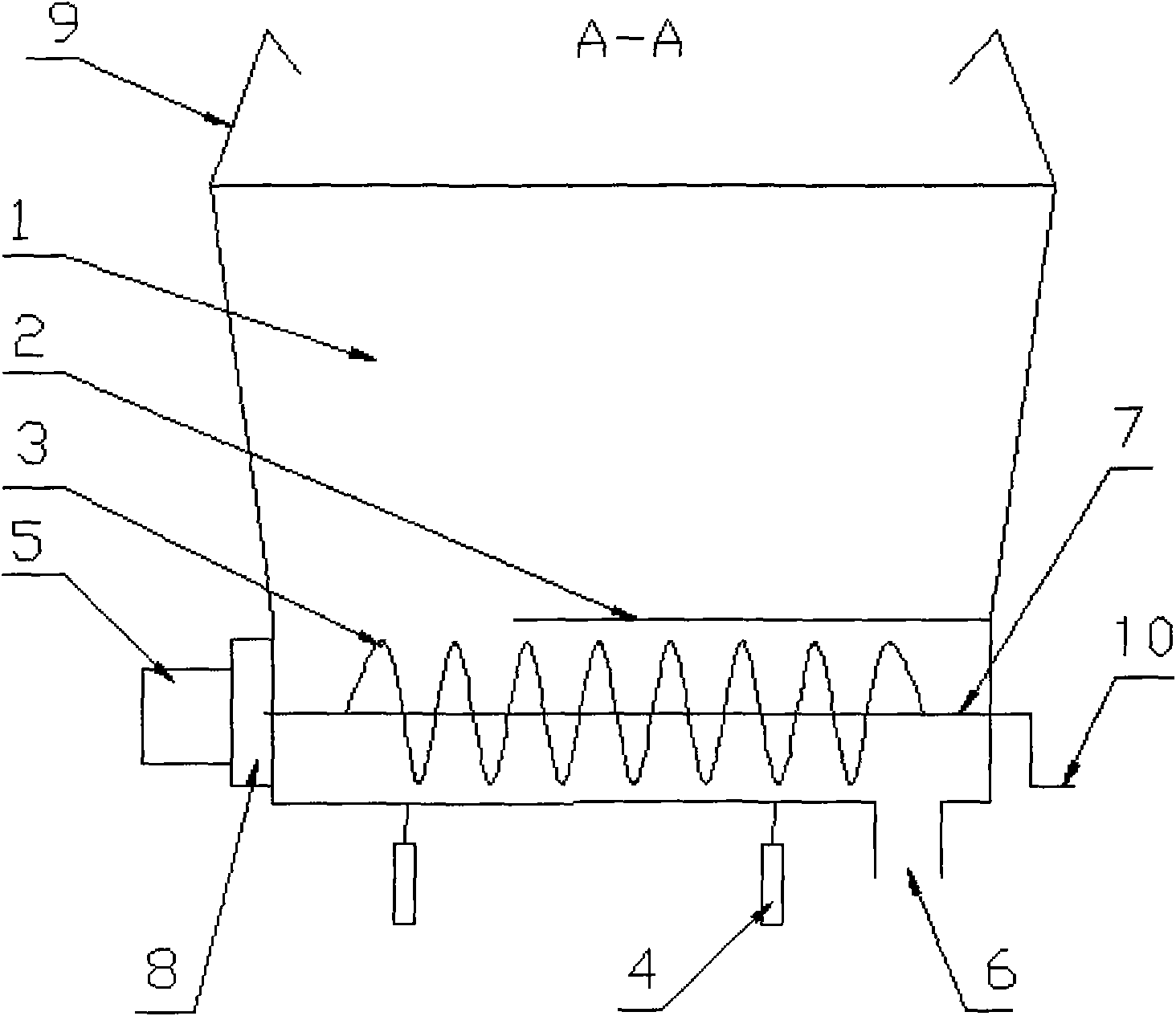

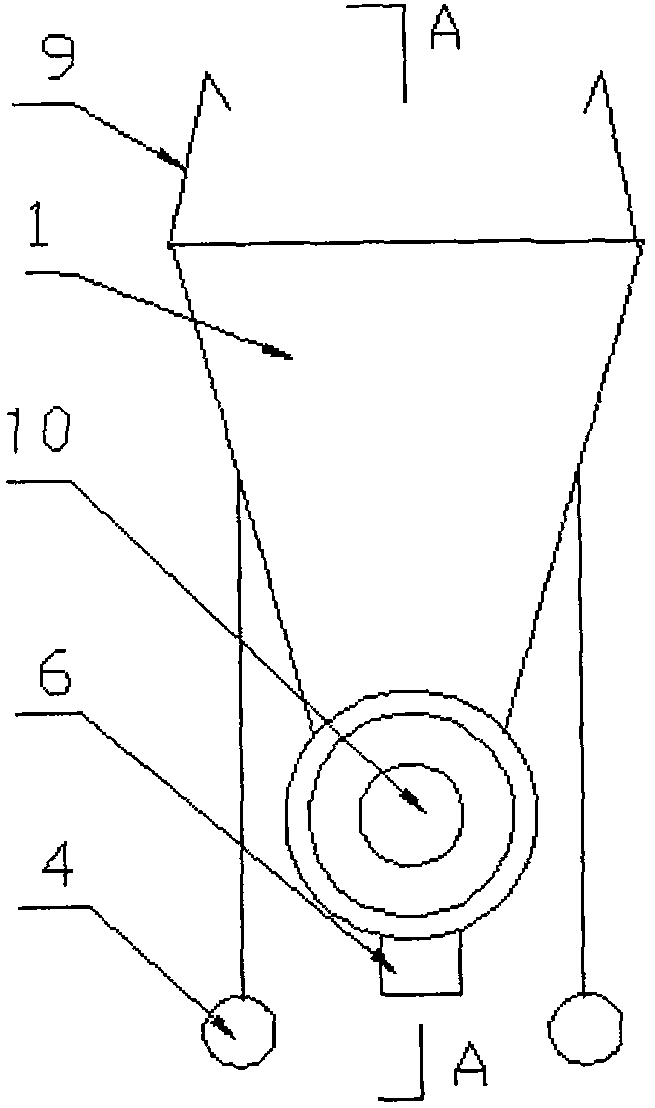

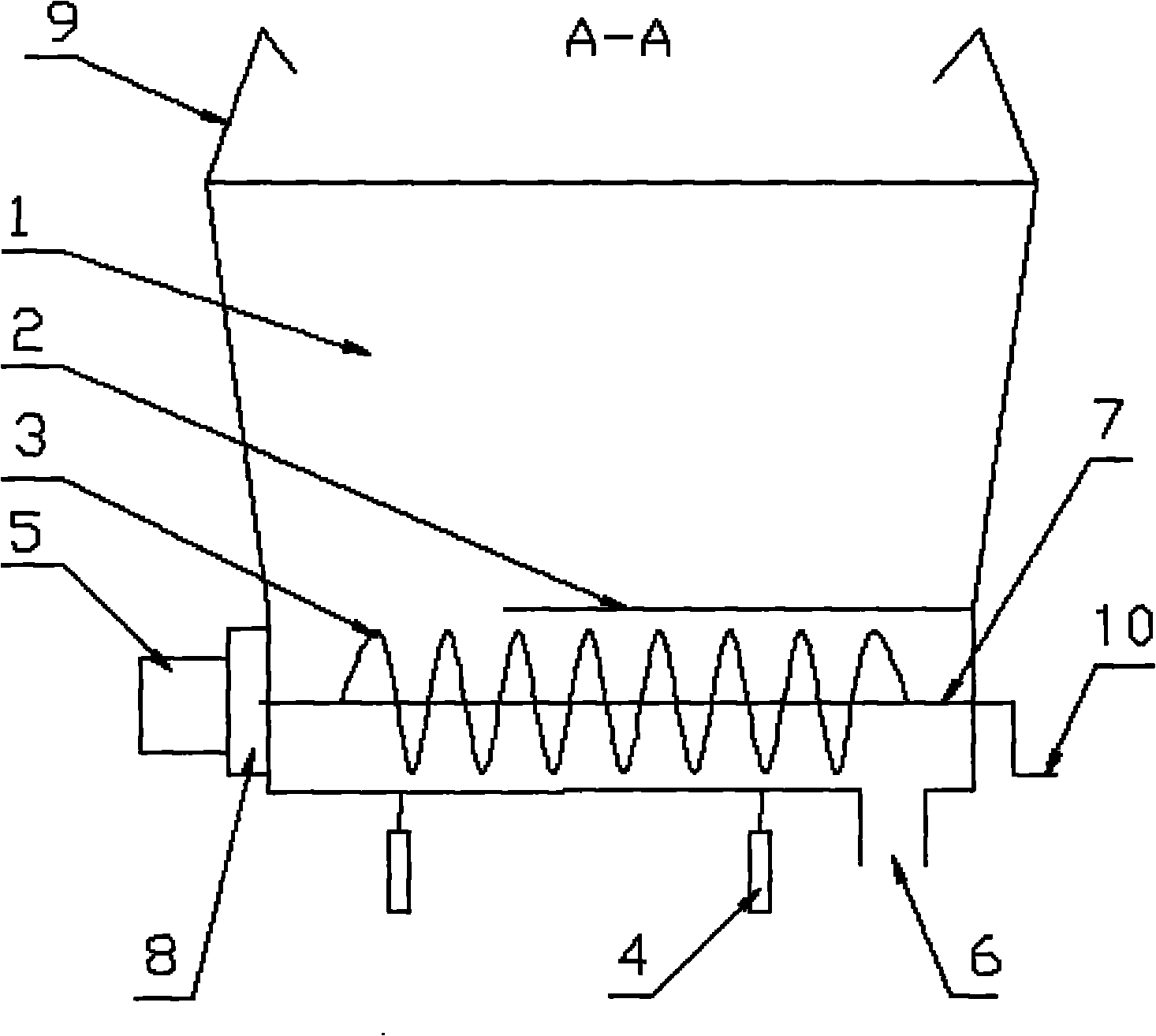

[0011] Make the barrel body (1) with sheet metal or other suitable materials, and simultaneously fix the suspension hook (9) and the barrel body (1) with an appropriate method, and connect the drive shaft (7) and the screw blade ( 3) Phase installation and fixing, and at the same time, install the transmission shaft (7) on the two ends of the inverted cylindrical inner cavity at the bottom of the bucket body (1) through bearings, and connect the arc-shaped baffle (2) to the bucket body in an appropriate way (1) The installation is fixed, and the length of the baffle is shorter than the length of the bottom of the barrel body (1). The installation of the baffle should ensure that the spiral blade (3) is exposed to an appropriate length in the length direction to facilitate the material Enter between the helical blades, at the same time, it should ensure that there is an appropriate gap with the helical blades (3) without touching. Install and fix the upper speed reducer (8) at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com