Method for setting exact filling level of cooling medium in cooling circuit of a vehicle

A technology of cooling medium and cooling cycle, which is applied in the direction of engine cooling, slack regulator, machine/engine, etc., and can solve problems such as overfilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

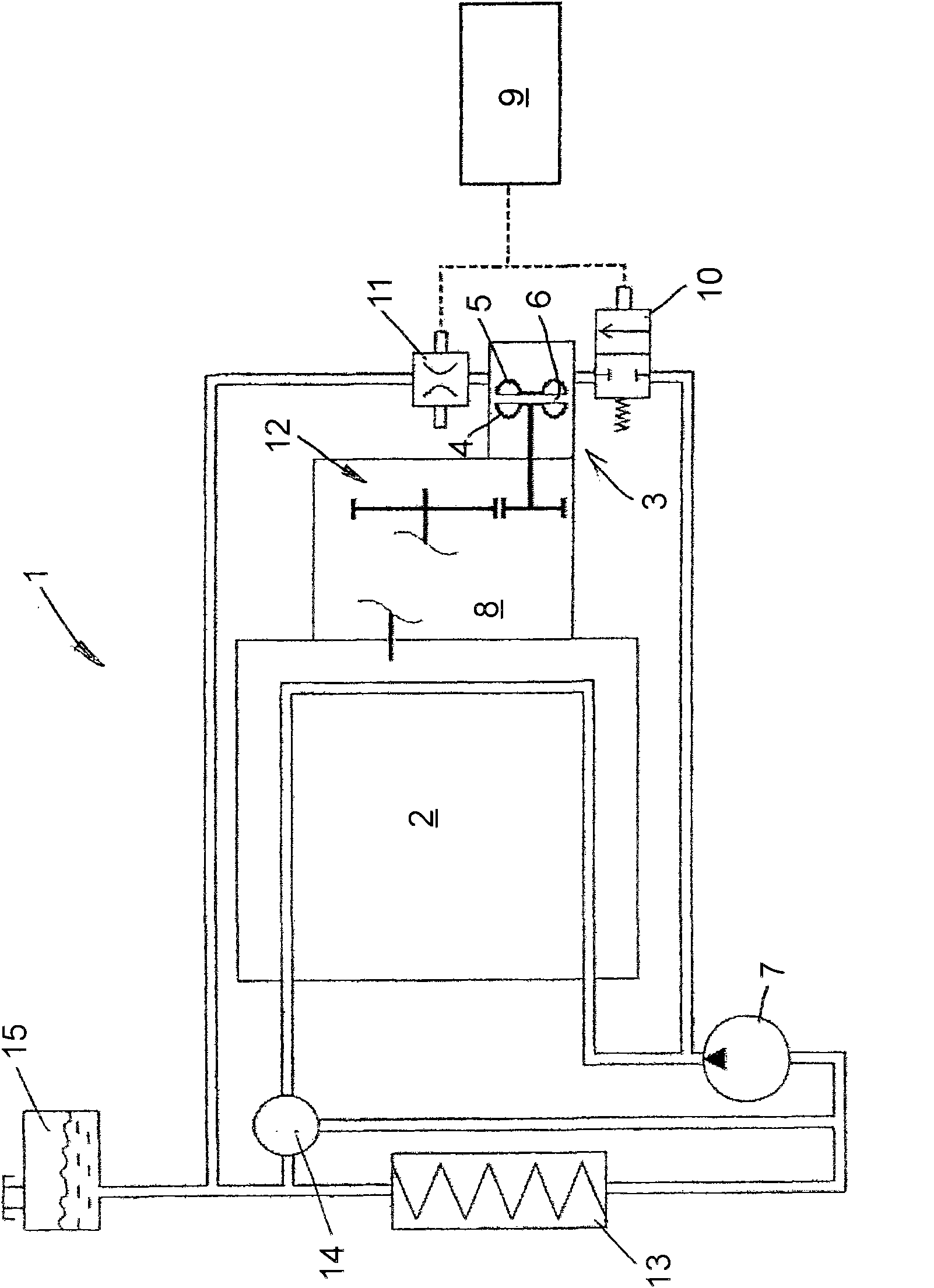

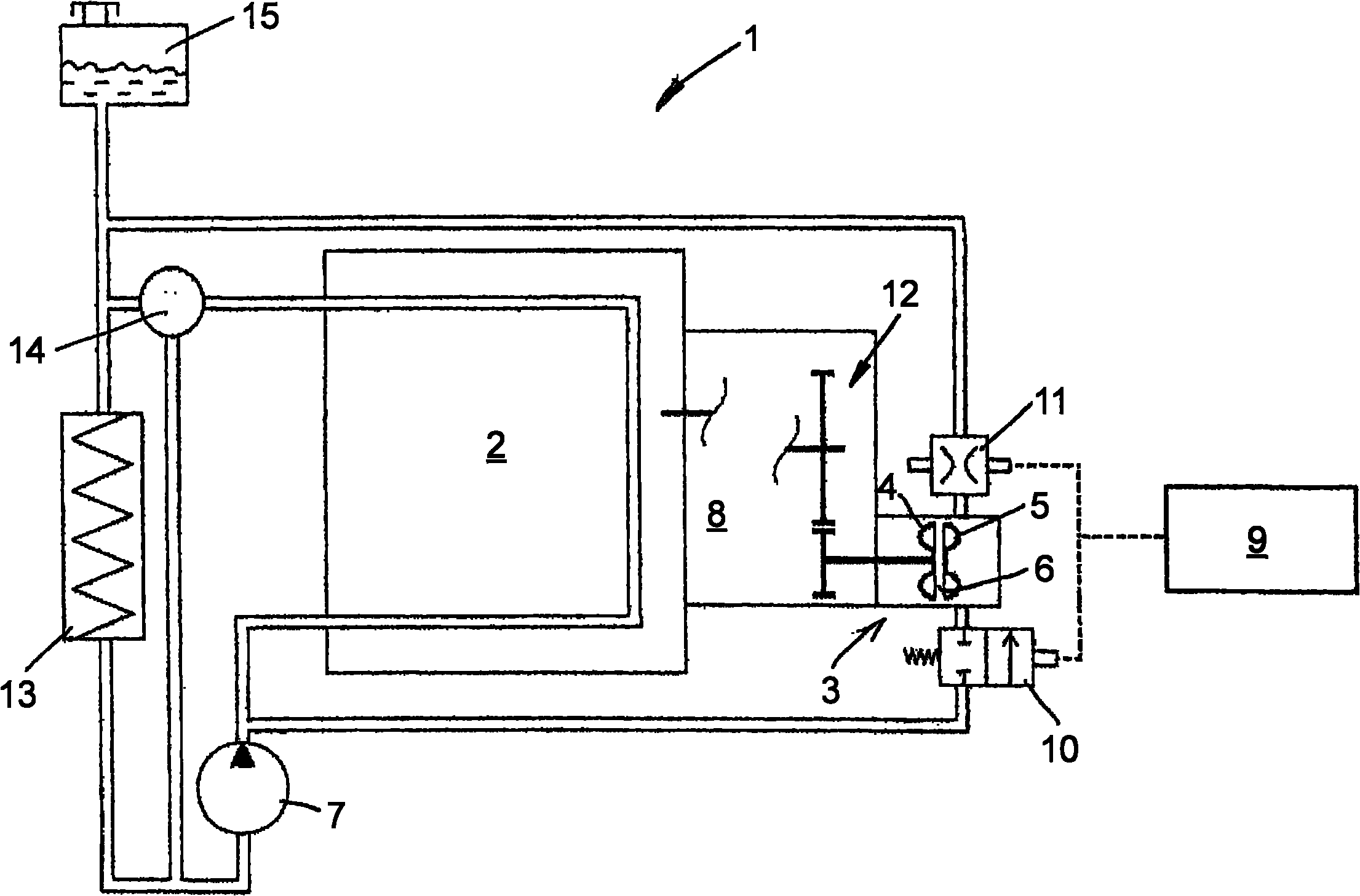

[0022] exist figure 1 A schematic diagram of a motor vehicle cooling circuit 1 according to a preferred embodiment is shown schematically in . A hydrodynamic retarder 3 is arranged in the cooling circuit 1 , comprising a main impeller 4 and a secondary impeller 5 , which form a torus-shaped working chamber 6 . The cooling medium of the cooling circuit 1 is simultaneously the working medium of the hydrodynamic retarder 3 . In this case, the secondary impeller 5 is designed to be stationary. Alternatively, the reducer 3 may also be designed as a counter-rotating reducer. The main impeller 4 is here driven in rotation by an auxiliary drive 12 of the transmission 8 , which is drivingly connected to the drive shaft of the drive motor 2 . The retarder 3 is therefore designed as a secondary retarder and brakes the motor vehicle depending on the driving speed. Alternatively, it is of course also possible to design the gear unit as a final gear unit and brake the motor vehicle as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com