Vapor pressure testing device for easy-sublimation solid energetic materials

A test device, vapor pressure technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of easy introduction of errors, high price, equipment damage, etc., and achieve the effect of safe operation process and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

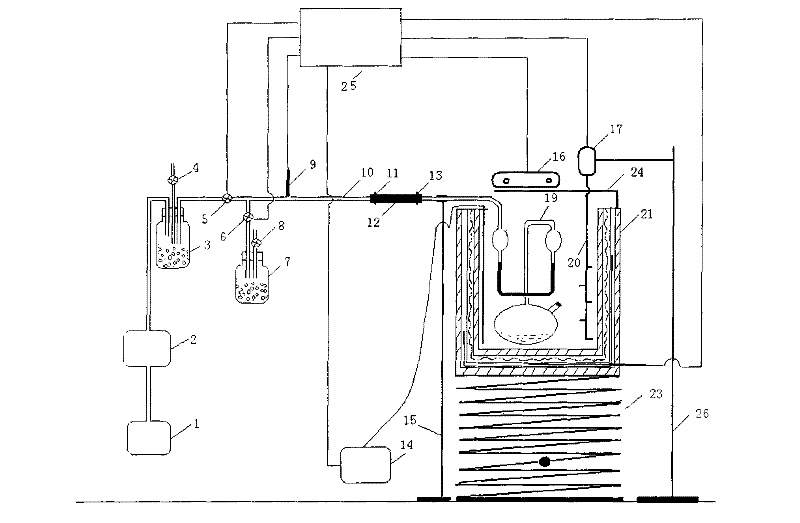

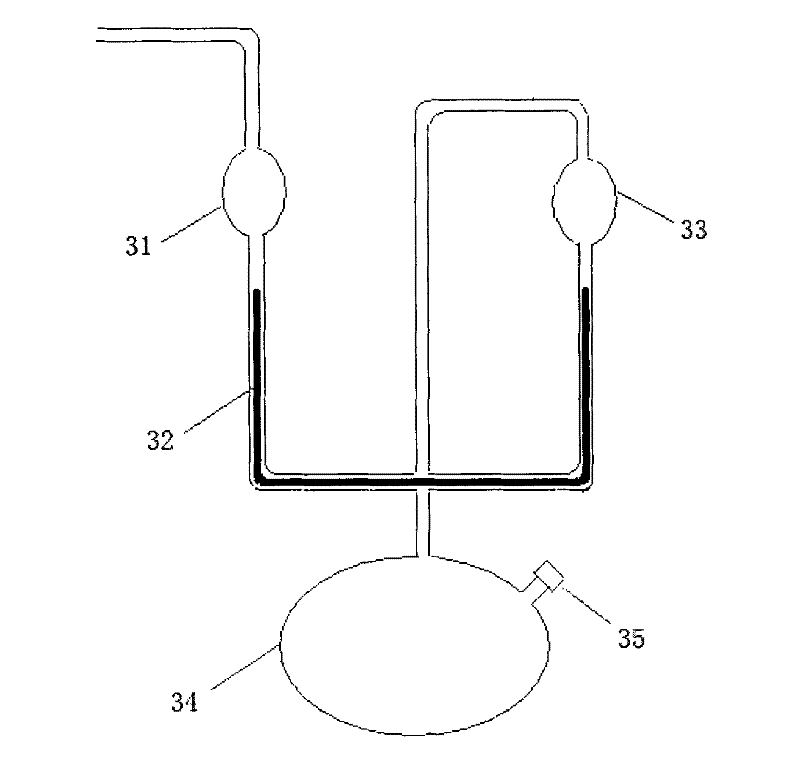

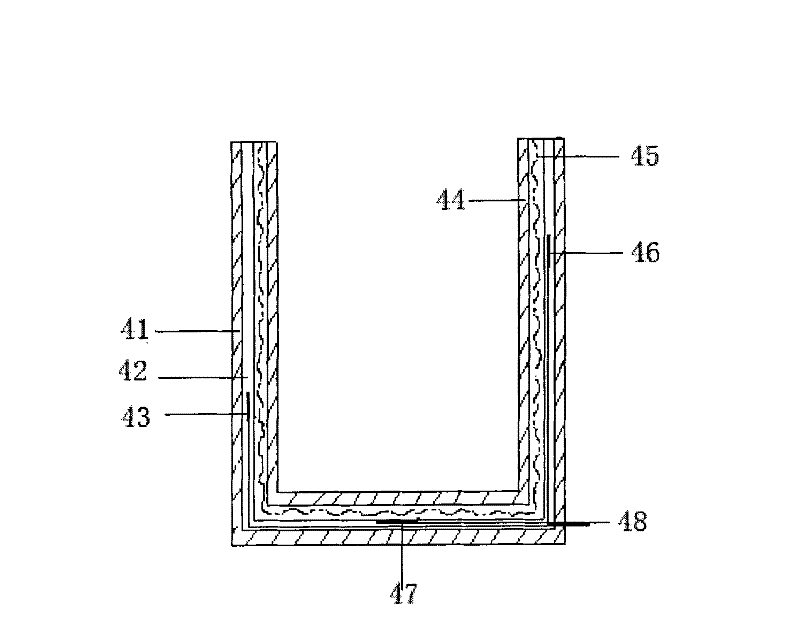

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 (the saturated vapor pressure test method of TNAZ)

[0051] A new high energy density energetic material 1,3,3-trinitroazetidine (TNAZ, C 3 h 4 o 6 N 3 ) is a four-membered small ring compound, and its thermal stability is slightly better than that of hexanitrohexaazaisopentazane (HNIW, C 6 h 12 o 12 N 12 ), the initial decomposition temperature is higher than 240°C, although its energy level is only between RDX and HMX, its melting point is lower than 100°C, and it can be combined with many energetic materials such as TNT, PETN, Tetryl, RDX and DNTF, etc. Forms eutectics and is therefore a potential energetic material for casting or fusion casting. So far, the saturation vapor pressure of TNAZ and its relationship with temperature have not been reported in the literature. According to the technological conditions of explosive melting and casting or explosive and propellant casting, this paper chooses 328.0 ~ 403.0K, uses the static heating and cool...

Embodiment 2

[0082] With n-valeric acid (C 5 h 10 o 2 ) to carry out verification test, the results are shown in Table 4:

[0083] Table 4 N-valeric acid vapor pressure measurement data table

[0084]

[0085] [1] Yao Yunbin, Xie Tao, Gao Yingmin, eds. Handbook of Physical Chemistry, P623. Shanghai: Shanghai Science Press. 1985.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com