Machine tool

A technology of machine tools and spindles, which is applied in the direction of turning equipment, tool holders, manufacturing tools, etc., can solve the problems of machine tool height increase, large-scale, complex structure of machine tool devices, etc., and achieve the effect of smooth transfer and easy cutting and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

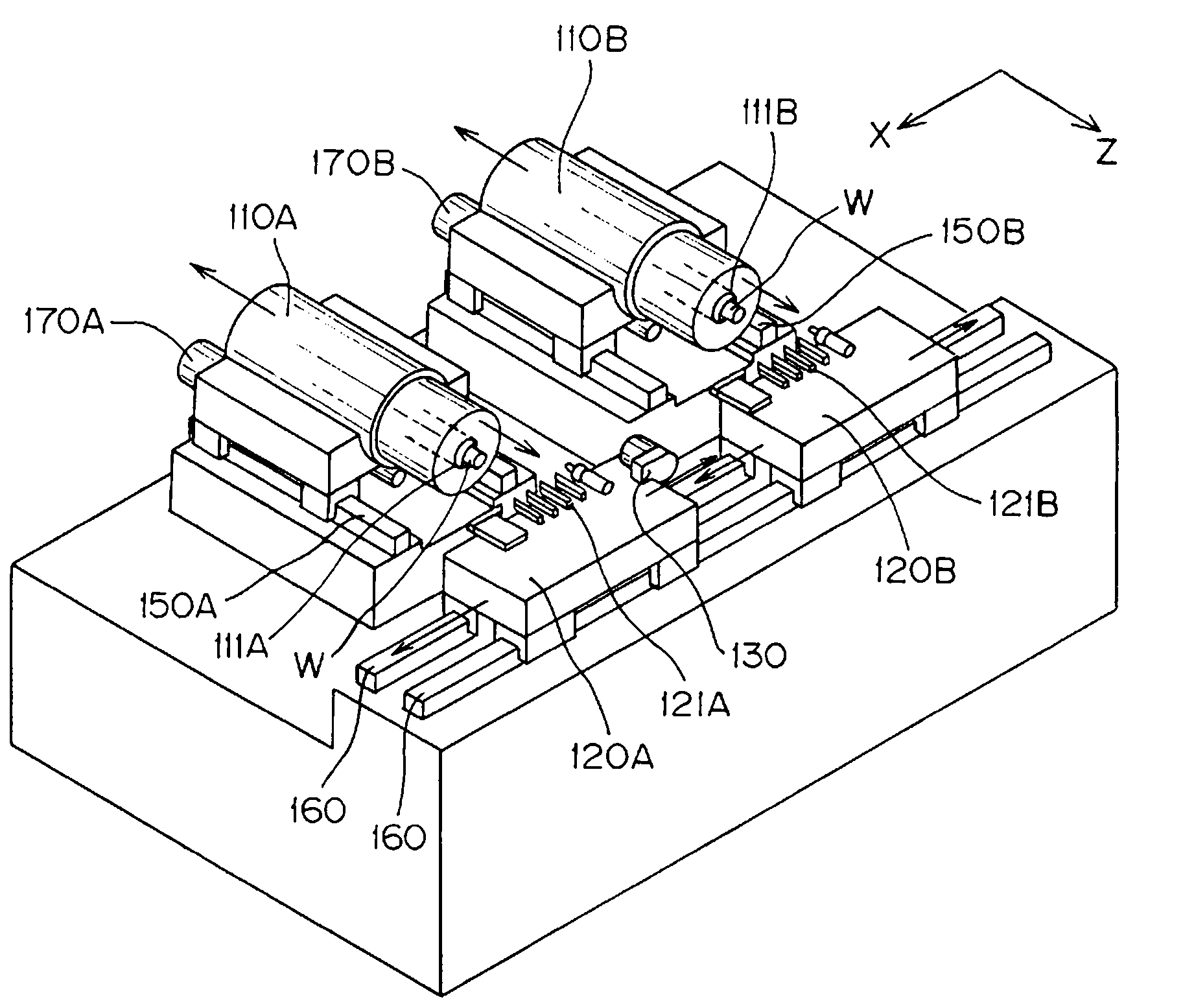

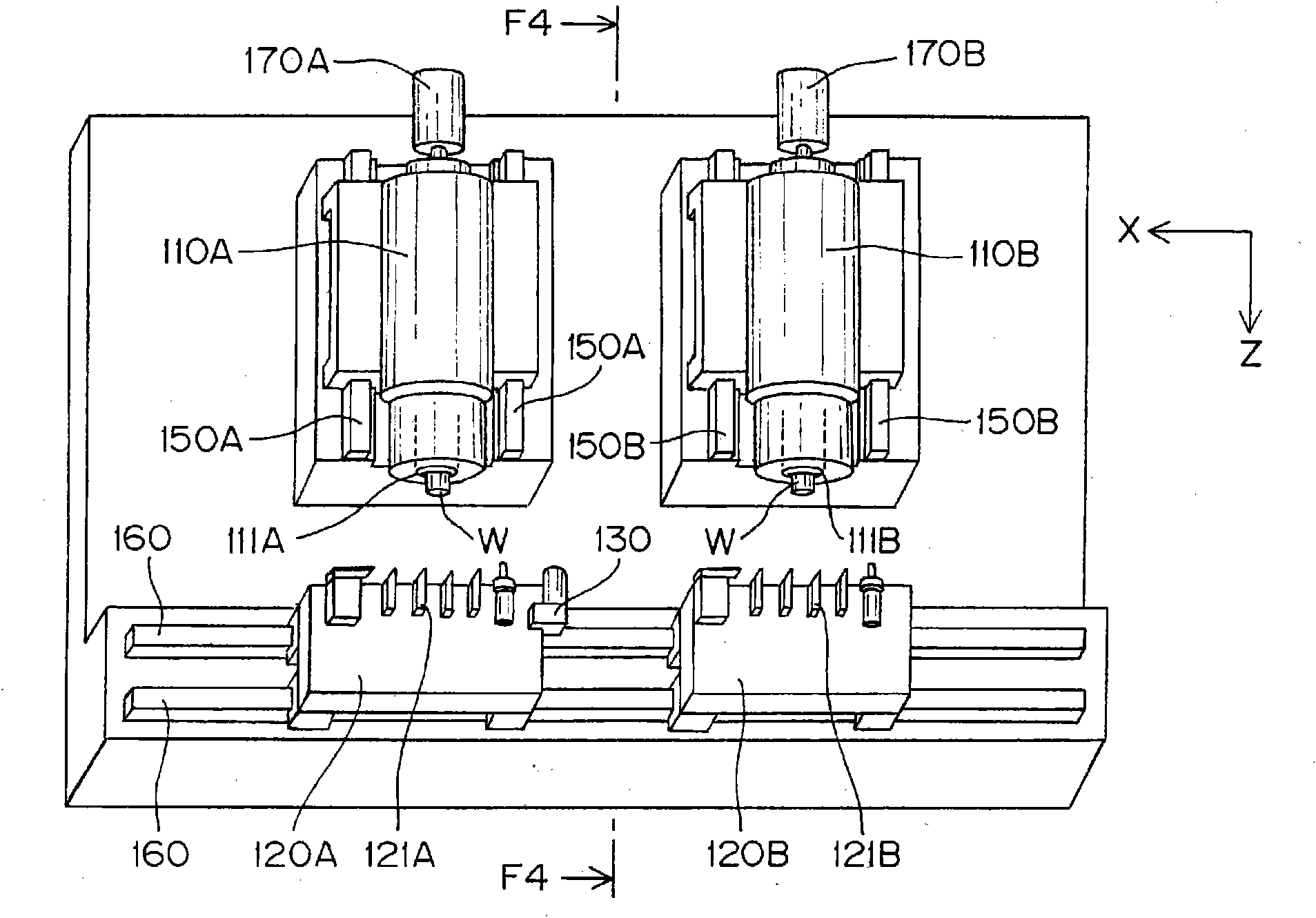

[0039] figure 1 The machine tool 100 of this embodiment is shown in part C, as Figure 2 to Figure 4 As shown, there are: a first headstock 110A that rotatably supports the first spindle 111A; and a second headstock 110B that rotatably supports the second spindle 111B.

[0040] The first headstock 110A and the second headstock 110B are arranged side by side in the left-right direction such that the axial direction of the first main shaft 111A is parallel to the axial direction of the second main shaft 111B. On one end face side of the first spindle 111A and the second spindle 111B, a clamper for gripping and holding the workpiece W is provided. The two main shafts 111A and 111B are arranged so that the end faces on the side of the holder face the same direction.

[0041] The first headstock 110A is slidably mounted on a rail 150A fixed to a base and extending in the Z-axis direction which is the axial direction of the two spindles 111A and 111B. The second headstock 110B i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com