Device for synchronously releasing a plurality of food sizing agents

A complex and slurry technology, which is applied in the field of food slurry extrusion and release devices, can solve the problems of quality and quantity that are difficult to meet, and achieve the effect of easy disassembly and cleaning and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

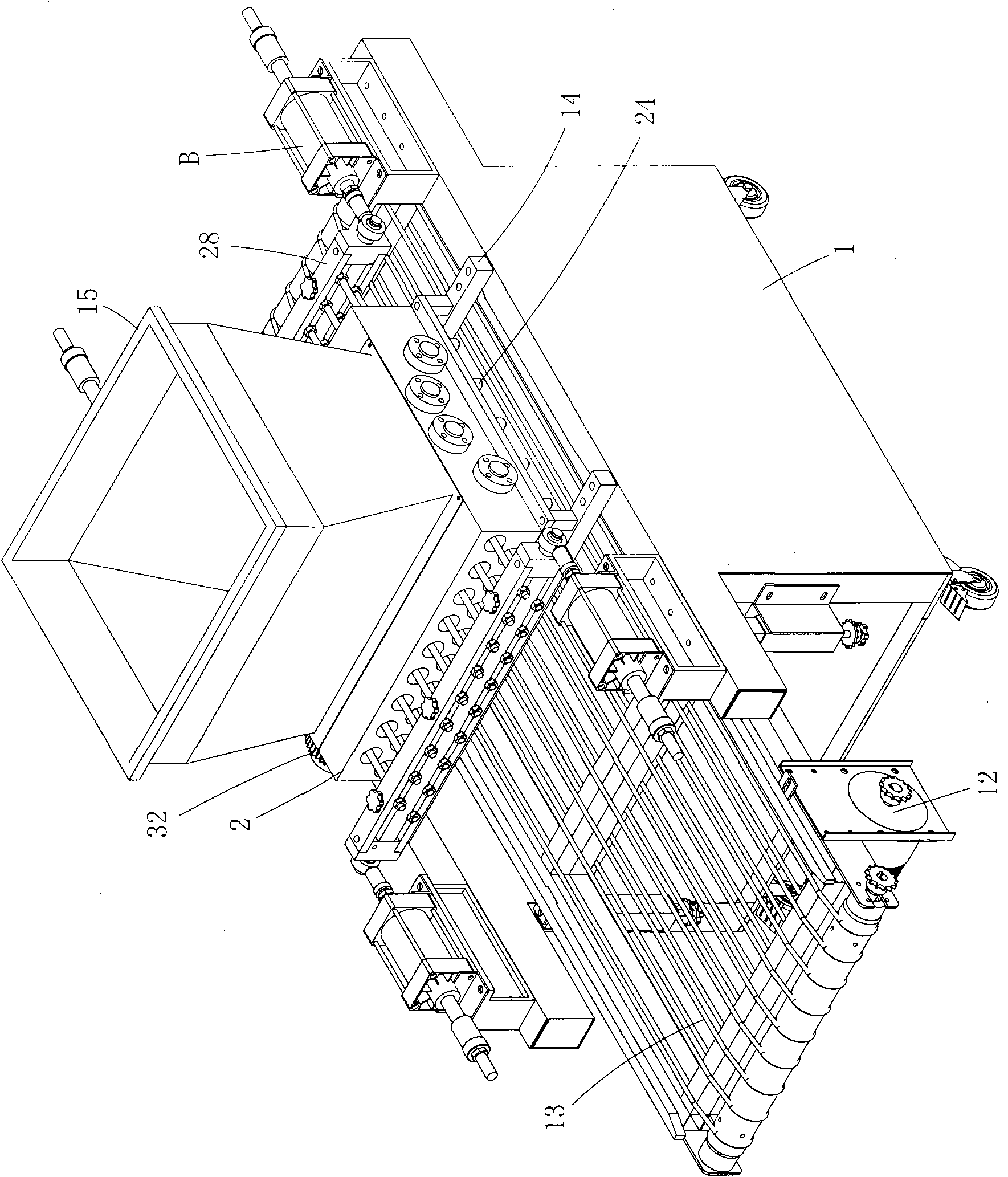

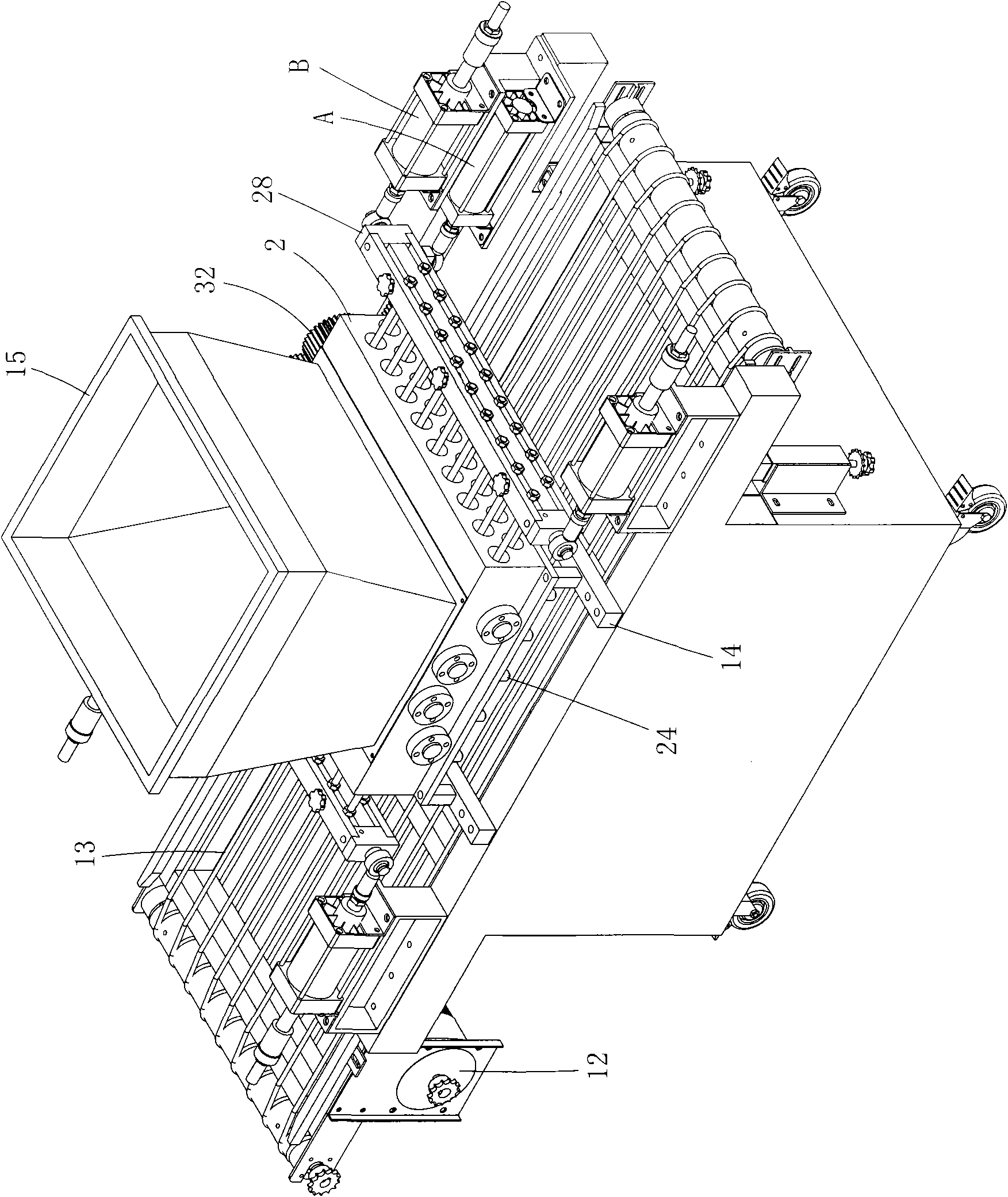

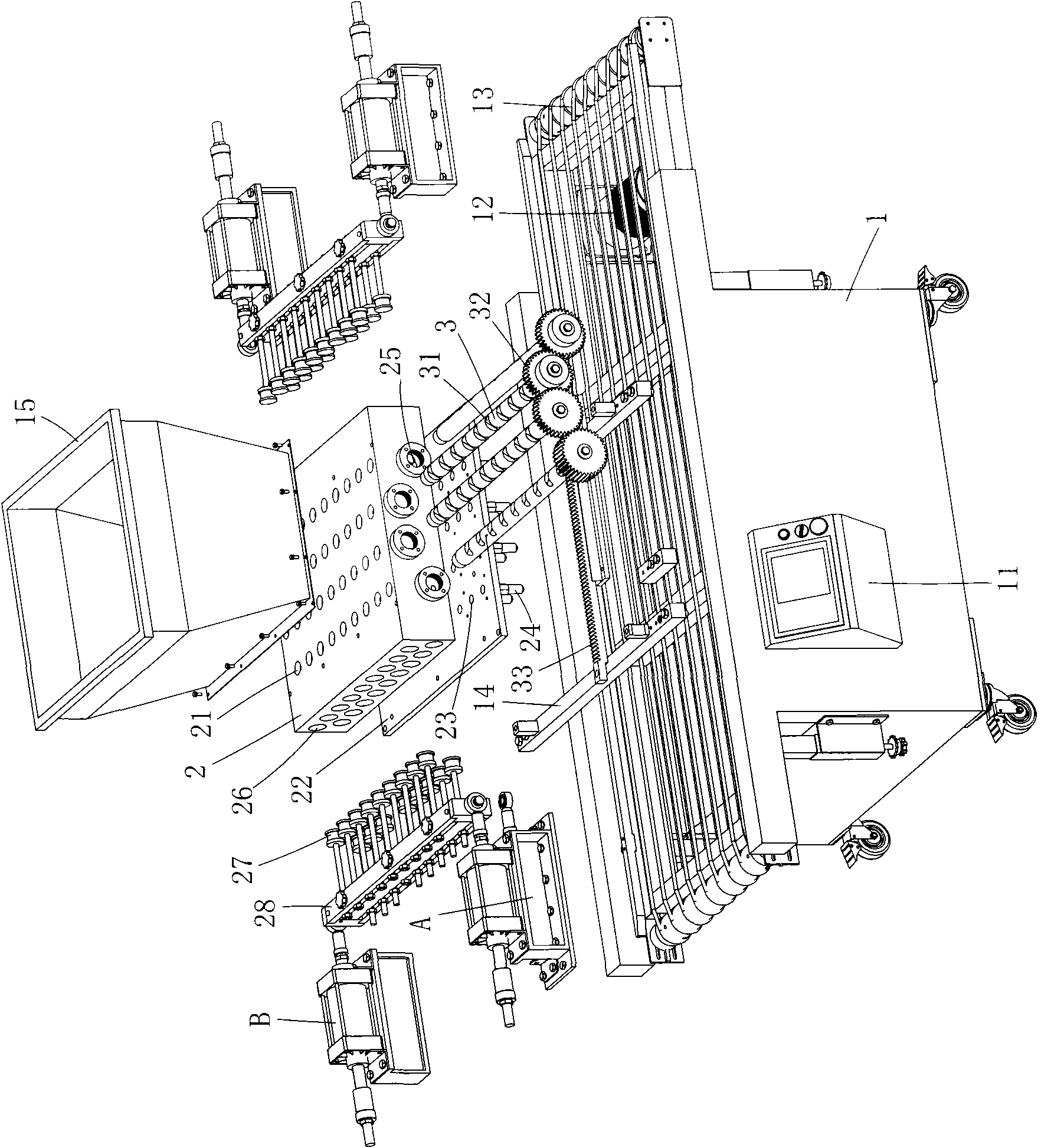

[0031] Please refer to Figure 1 to Figure 5 As shown, the present invention "multiple synchronous release device for food slurry" has a control box 11 on the machine platform 1, and a conveyor belt 13 driven by a motor 12 and several cylinders A and B are arranged above the machine platform 1. The built-in control circuit in the control box 11 described above can be used for input setting to control the actions of the air cylinders A, B and the conveyor belt 13.

[0032] A group of fixed brackets 14 are fixed on the machine table 1 above the conveyor belt 13, and a cylinder base 2 is fixed on the fixed bracket 14. A plurality of longitudinal apertures 21 run through the cylinder base 2 longitudinally, and a funnel is fixed above the cylinder base 2. 15. A support plate 22 is fixed under the cylinder base 2, and the support plate 22 is provided with communication holes 23 corresponding to the above-mentioned longitudinal apertures 21, and a plurality of extrusion nozzles 24 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com