Method for manufacturing large-diameter thick-wall seamless steel pipe

A seamless steel pipe and manufacturing method technology, applied in the field of iron and steel smelting, can solve the problem of high steel pipe price, achieve the effect of steel pipe quality satisfaction and obvious cost competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

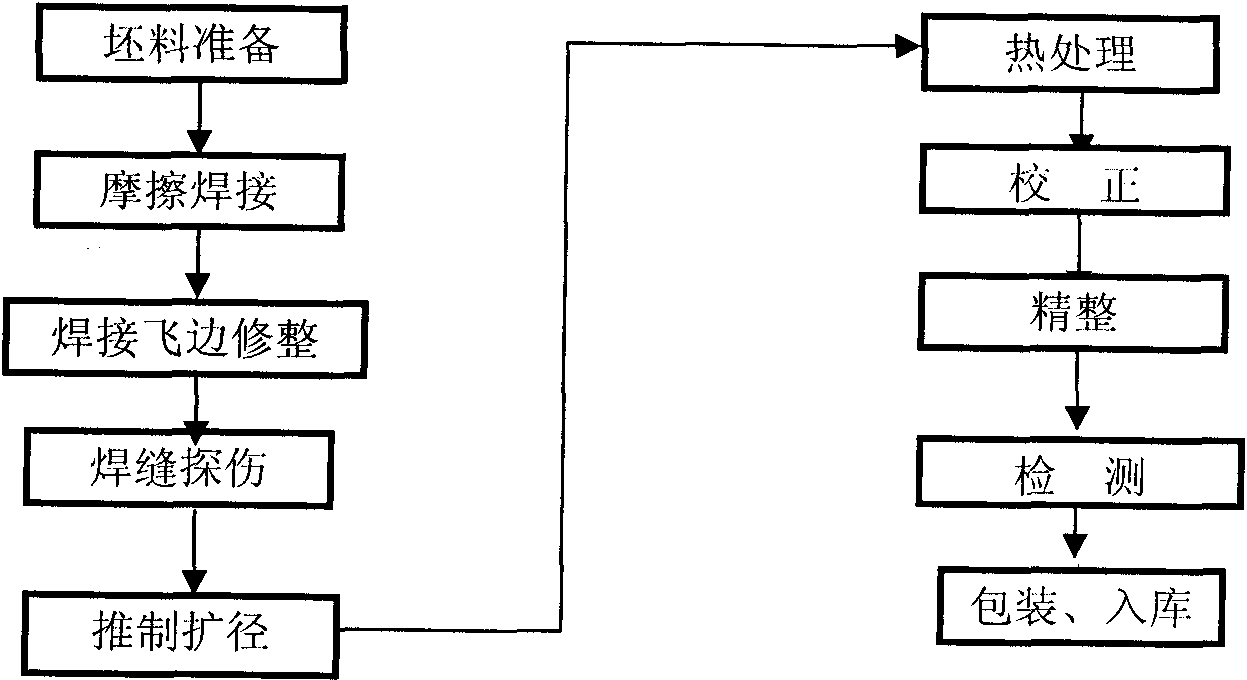

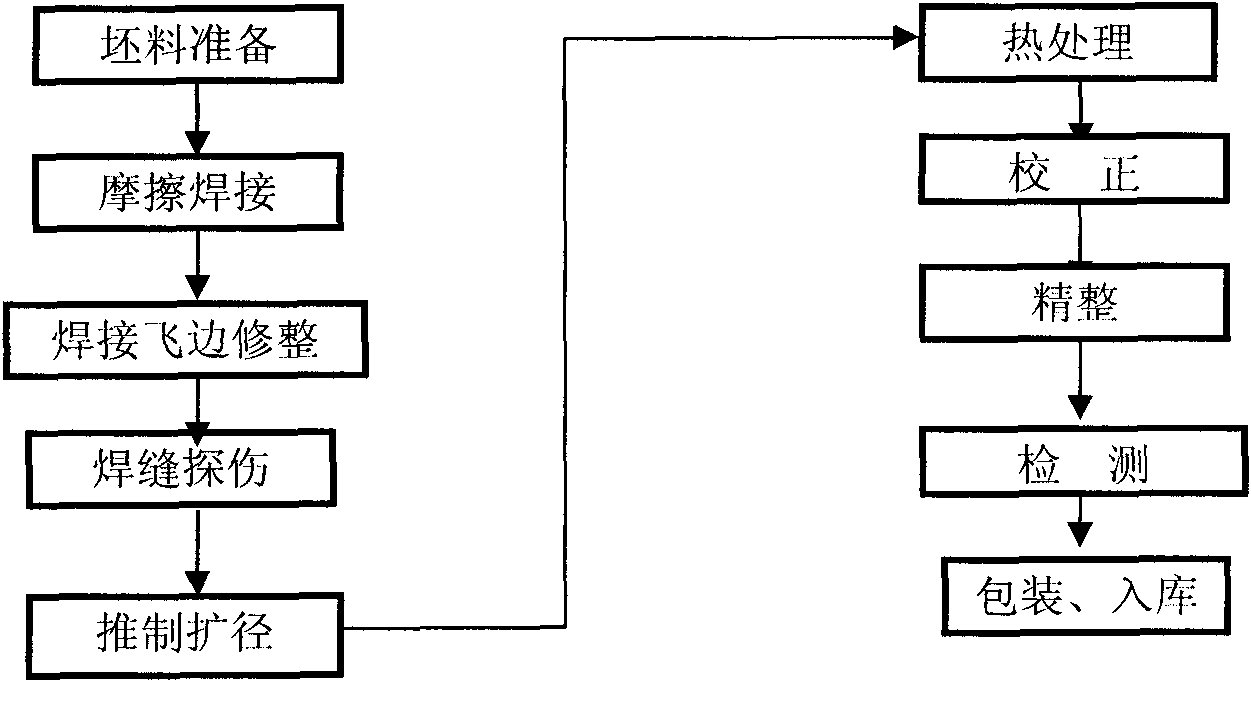

Method used

Image

Examples

Embodiment 1

[0021] For example, to produce steel pipes of φ1200x60x6500mm

[0022] 1. Two steel pipes of φ580x90x5000mm can be selected;

[0023] 2. Joint preparation, the flatness of the butt joint surface is ≤0.1mm, and the perpendicularity to the axis of the steel pipe is ≤0.15mm;

[0024] 3. Use a friction welding machine to butt the steel pipe into a tube blank of φ580x90x10000mm;

[0025] 4. Trim the flash generated by friction welding, and smooth the weld flash and the inner and outer surfaces of the steel pipe;

[0026] 5. Non-destructive testing of welds is required to be carried out in accordance with the flaw detection standards of finished steel pipes;

[0027] 6. Use the push pipe expander to expand the diameter of the pipe blank after butt jointing to φ1200x60x6550mm in 4 passes, and the diameter expansion ratio of each pass is about 1.2;

[0028] 7. Heat treatment;

[0029] 8. Calibrate and finish the steel pipes that have passed the heat treatment to meet the size requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com