Safety light curtain sensor without dead zone

A technology of safety light curtains and sensors, which is applied in the direction of maintenance and safety accessories, optical device exploration, metal processing machinery parts, etc., can solve the problems of blind spots and hidden safety hazards in light curtain sensors, and achieve the elimination of detection blind spots, improve safety performance, Increase the effect of extension modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

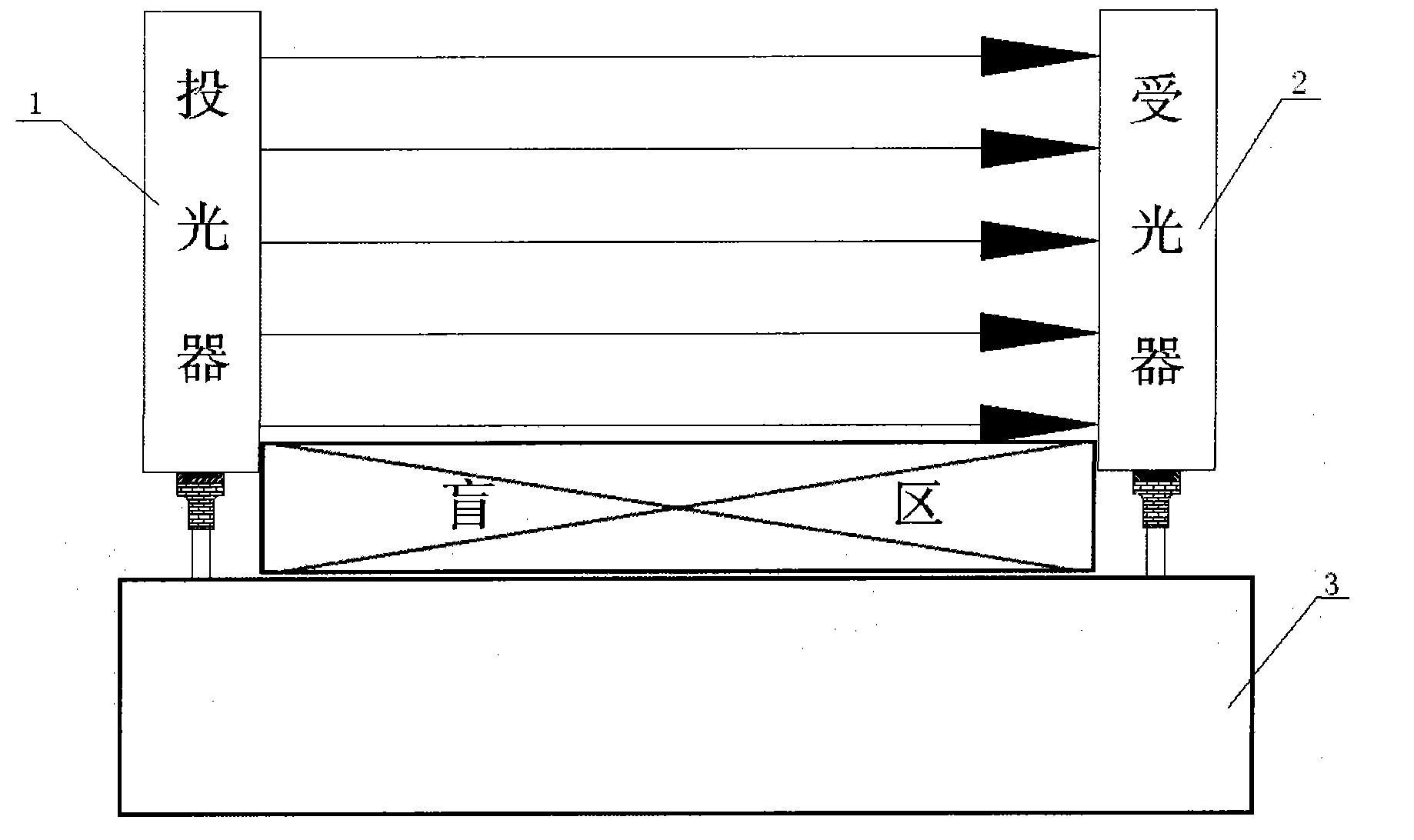

[0010] Such as figure 1 The schematic diagram of the use of the traditional light curtain sensor shown in the figure shows that there is a large detection blind spot between the machine tool 3 table and the first light at the bottom of the light curtain composed of light emitter 1 and light receiver 2. Hands can completely invade, and the light curtain sensor cannot detect Sending out an alarm signal will cause personal danger.

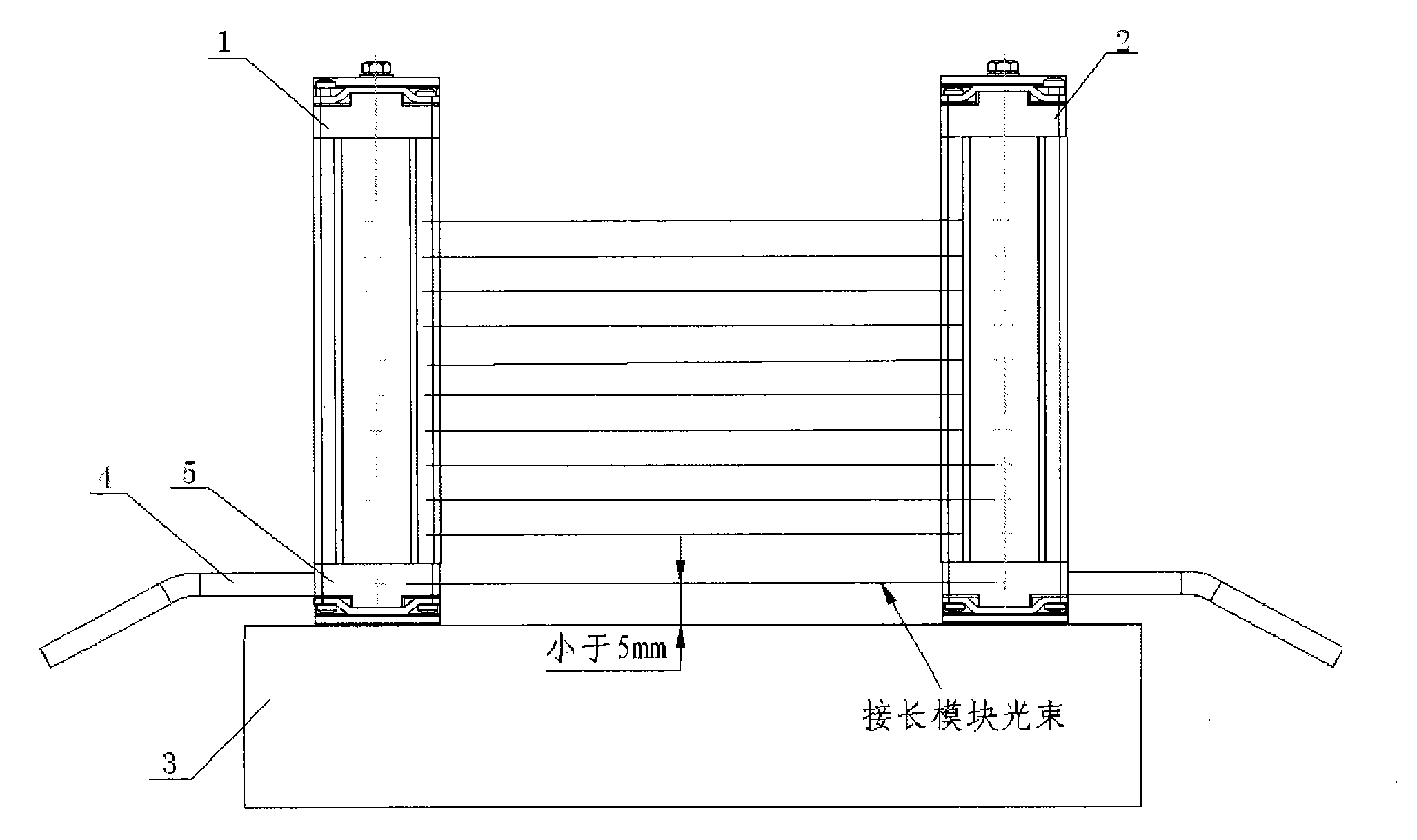

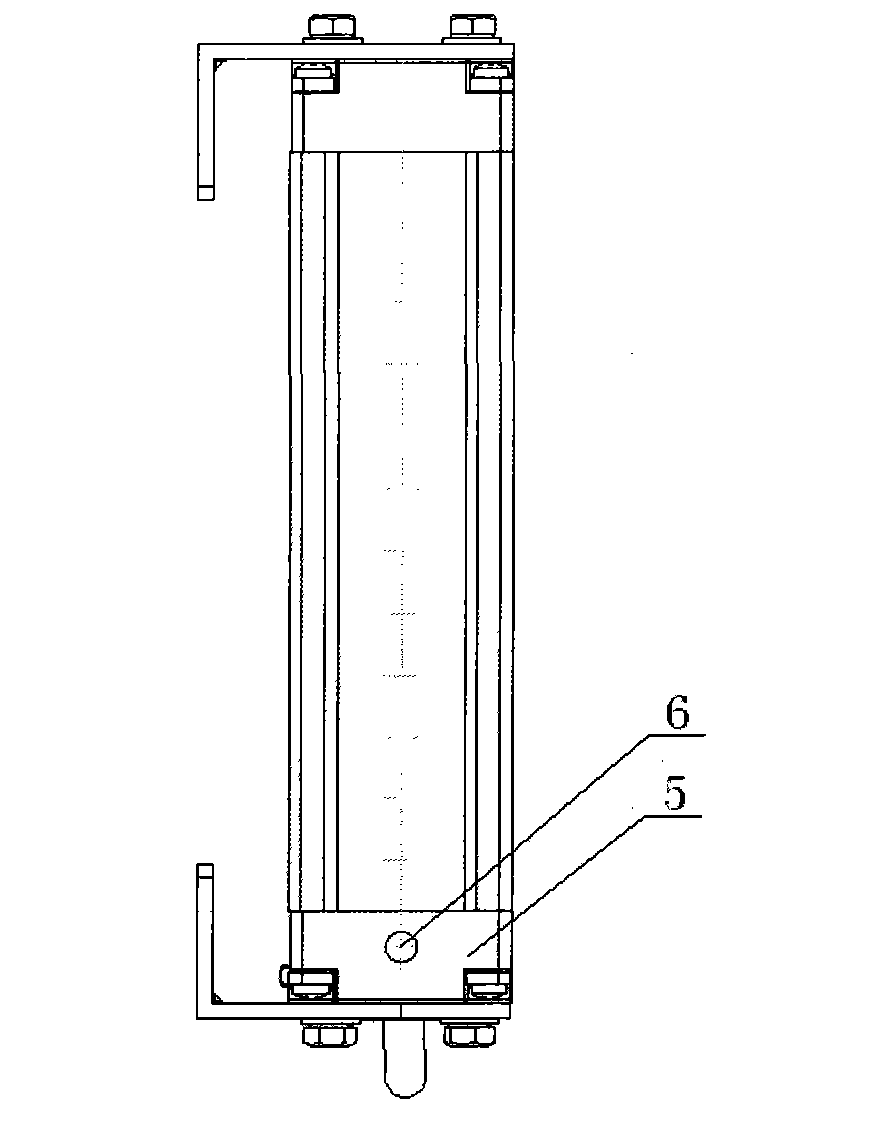

[0011] Such as figure 2 , 3 The schematic diagram and appearance structure diagram of the safety light curtain sensor without blind zone are shown. This light curtain sensor without blind zone adopts the way of output line 4 side outlet, and the extension module 5 is installed at the bottom of the light emitter 1 and light receiver 2 to detect the position of the blind zone. It is internally connected with the light curtain sensor. In order to prevent the increased light beam from shining on the machine tool 3 table, the extension module 5 uses the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com