Adhesive film and wafer processing tape

A technology for bonding films and wafers, applied in the direction of adhesives, film/sheet adhesives, semiconductor devices, etc., it can solve the problem of not being able to fit wafers, and achieve the effect of ensuring adhesion and reducing chip breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

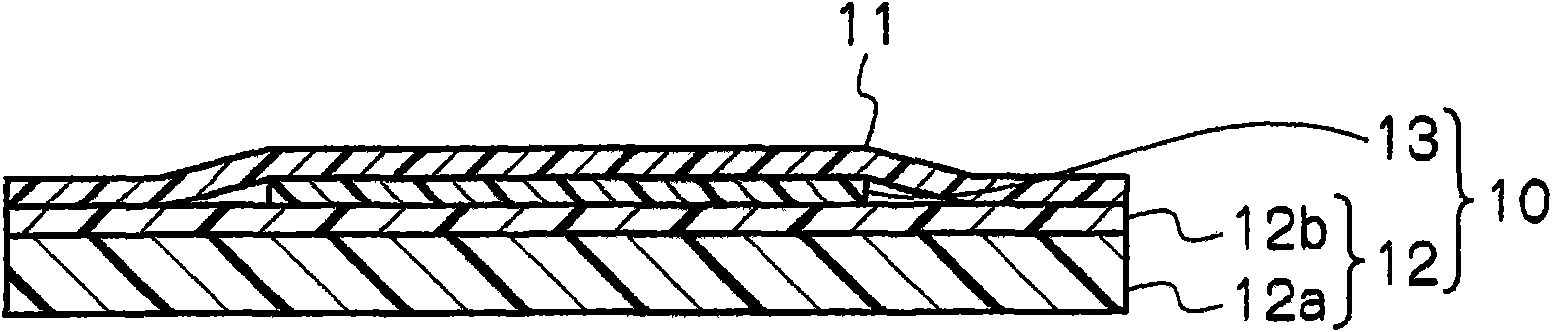

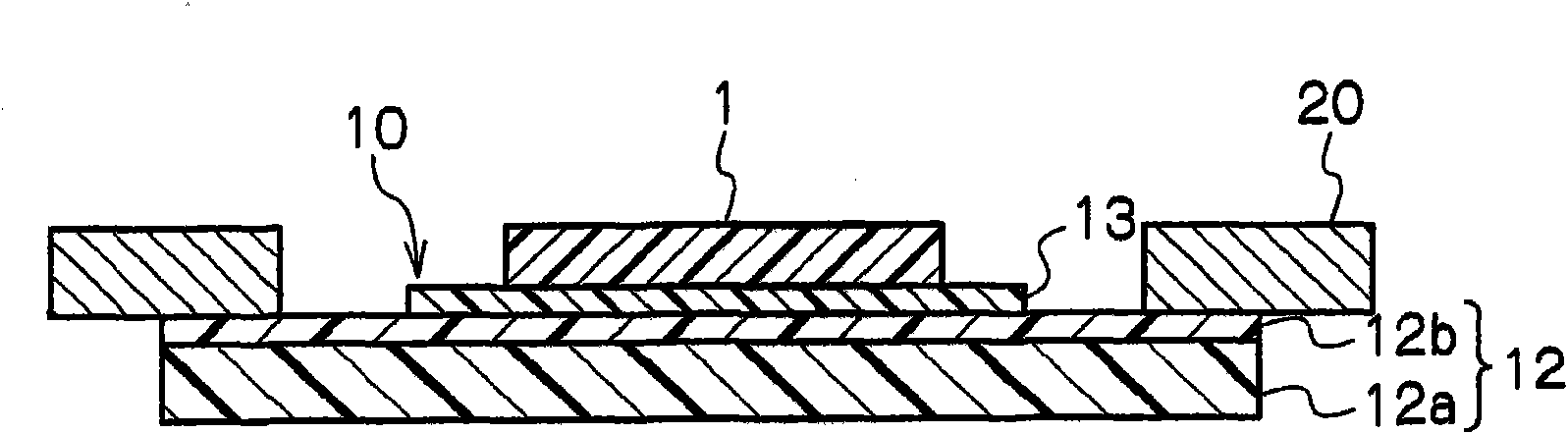

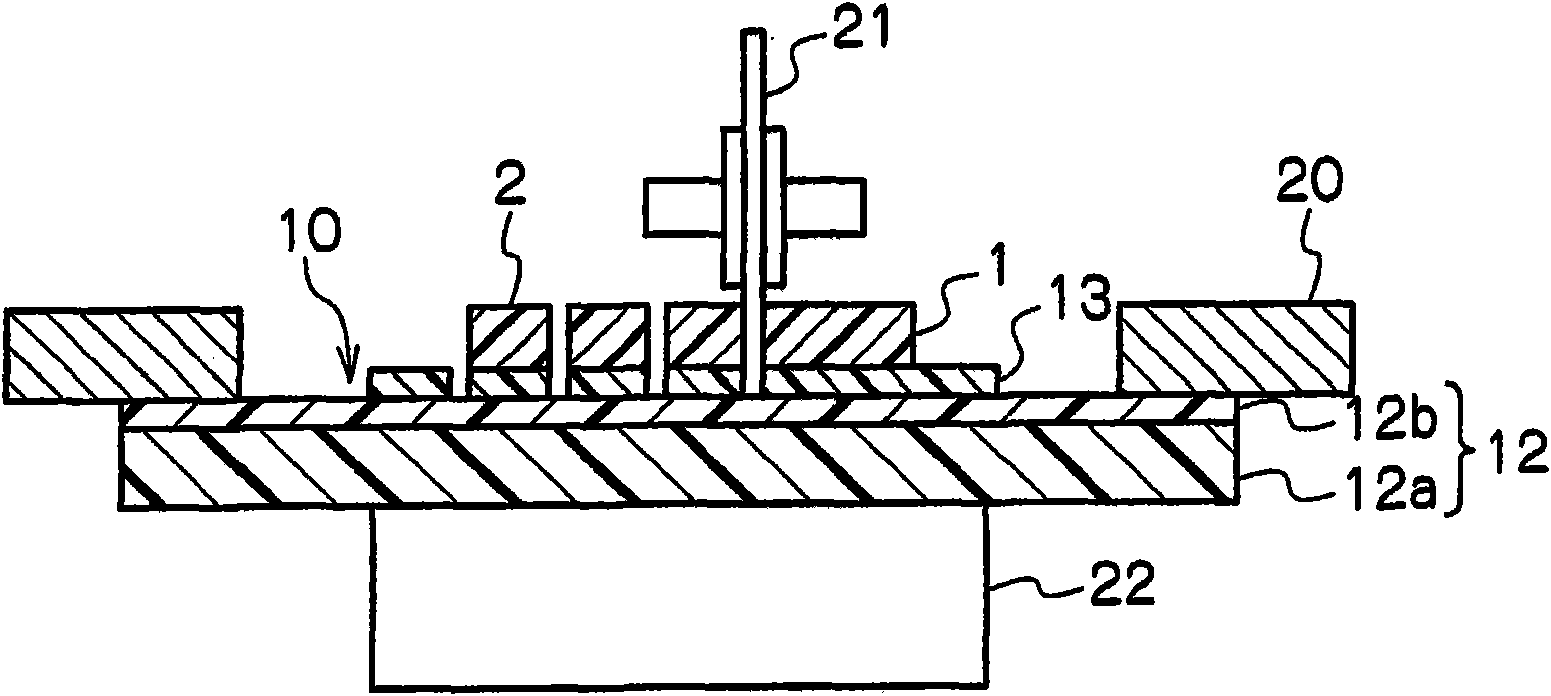

Image

Examples

Embodiment 1

[0103] To the above-mentioned acrylic polymer (1) obtained, each material shown in Table 1 was added in the compounding ratio shown in the same table, and the varnish of the adhesive material composition was obtained. The obtained varnish was coated on a polyethylene terephthalate (PET) film with a thickness of 50 μm, and heated and dried at 120° C. for 10 minutes to form a coating film in a B-stage state with a film thickness of 50 μm to produce an adhesive film. The adhesive film of Example 1 of the agent layer.

Embodiment 2

[0105] The materials shown in Table 1 were added to the obtained acrylic polymer (1) in the compounding ratio shown in the same table, and the adhesive film of Example 2 having an adhesive layer was produced in the same manner as in Example 1.

Embodiment 3

[0107] The materials shown in Table 1 were added to the obtained acrylic polymer (1) in the compounding ratio shown in the same table, and the adhesive film of Example 3 having an adhesive layer was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com