Vibration damper and downhole drill comprising the same

A vibration damping device and drill pipe technology, which is applied in the direction of the driving device, drill pipe, and drill pipe for drilling in the borehole, can solve the problems of limited elastic deformation, limited vibration damping effect of the vibration damping device, and strong impact, etc., to achieve The effect of reducing impact vibration and optimizing vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

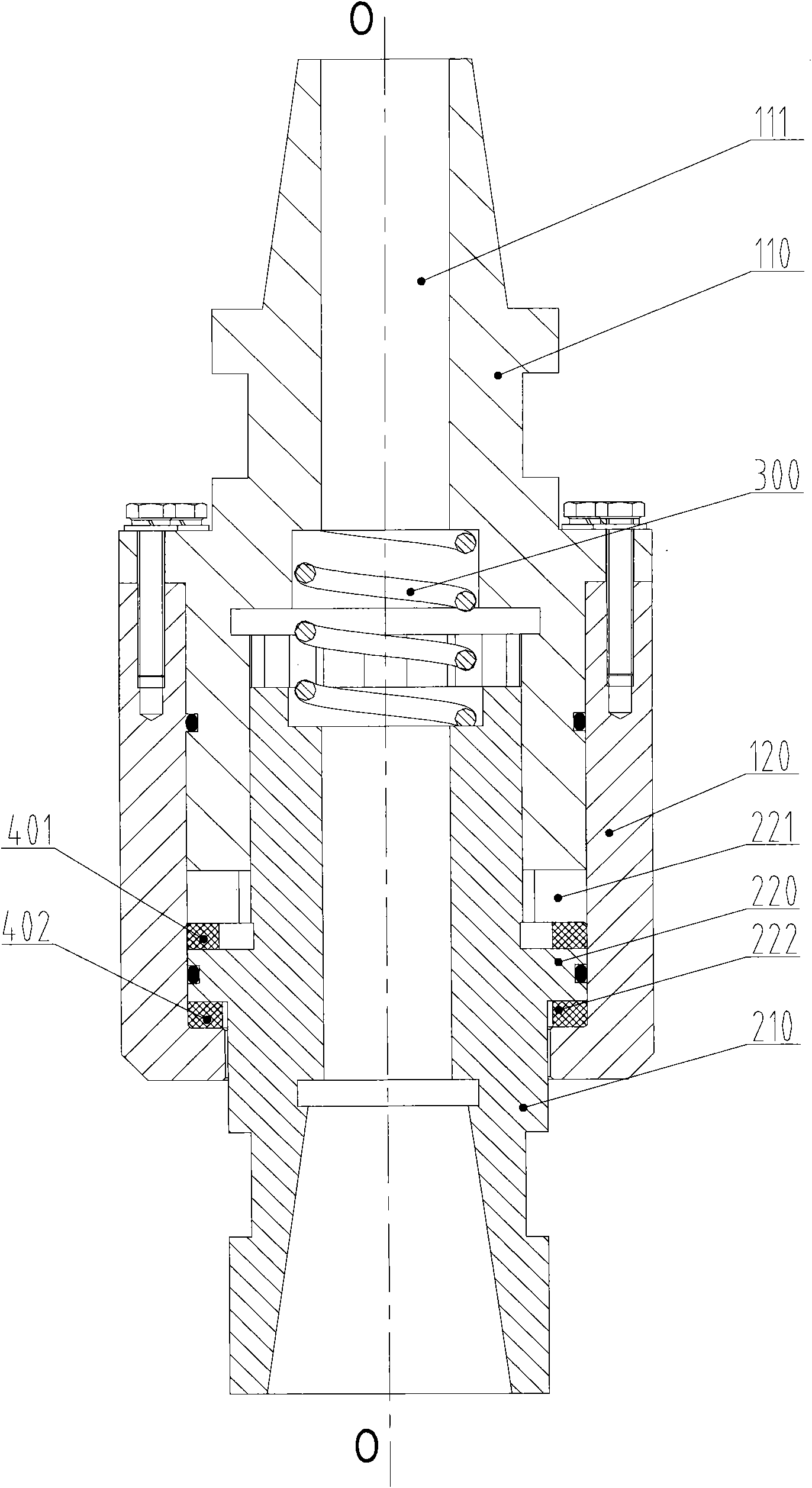

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

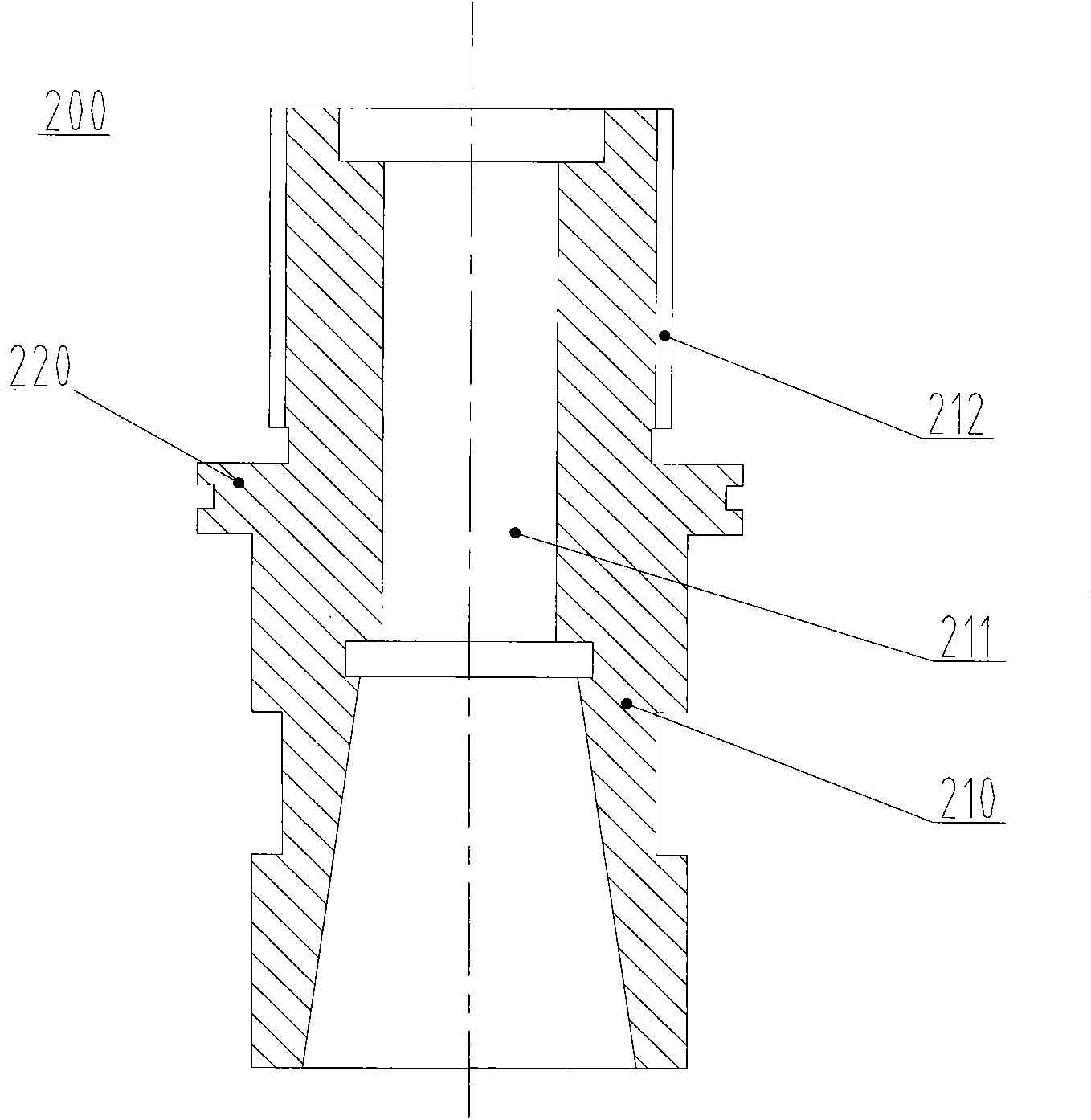

[0036] The vibration damping device provided in this embodiment includes a first joint 100 and a second joint 200 . The structures of the first joint 100 and the second joint 200 are described respectively below.

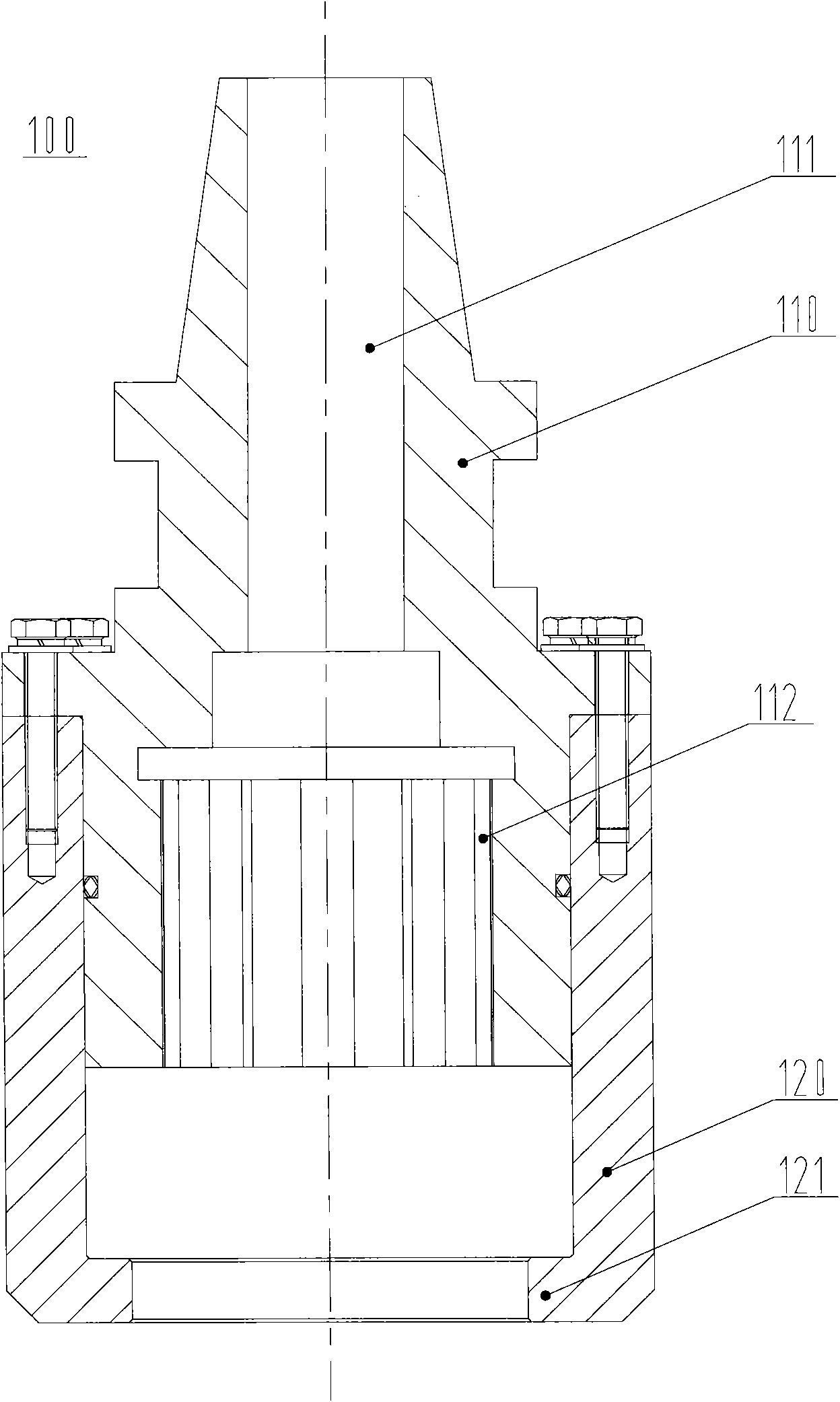

[0037] Please refer to figure 1, which is a schematic structural diagram of the first joint in the vibration damping device provided by the embodiment of the present invention. The first joint 100 includes a first joint body 110 and a sleeve 120 , and the first joint body 110 and the sleeve 120 are fixed together by fasteners; the first joint body 110 has a central through hole 111 inside. An inner spline groove 112 is provided near the lower end of the first connector body 110 , and the centerline of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com